System for transporting plate-shaped bottom die

A bottom mold, plate-shaped technology, applied in the field of plate bottom mold transportation systems, can solve the problems of error-prone transportation supervision effects at the end of transportation, and achieve the effect of reducing the transportation error rate and ensuring the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

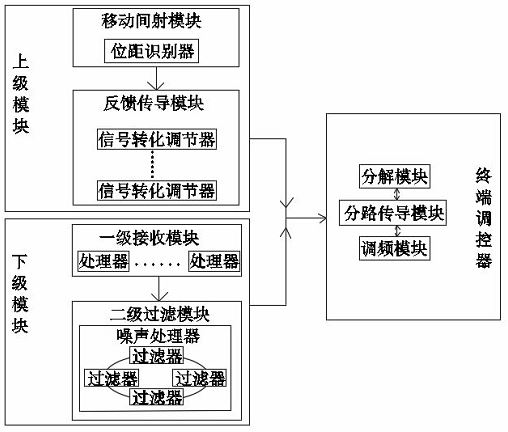

[0022] Please refer to the attached figure 1 , this embodiment provides a system for transporting a plate-shaped bottom form. The system for transporting a plate-shaped bottom form is mainly used to solve the problems in the prior art that the transportation terminals of different plate-shaped bottom forms are prone to errors and the transportation supervision effect is poor. The system has been It is in the stage of actual use, and it should be noted that the object of the plate-shaped bottom form in this application is a plate-shaped plate with different sizes and materials, and the use environment of this system is positioning and transportation within the scope of the construction site, and the transportation method is semi-automatic For transportation, construction workers only need to follow the car.

[0023] This embodiment specifically includes an upper-level unit used for signal generation and a lower-level unit that cooperates with the upper-level unit to receive sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com