Waviness measuring device and use method

A measuring device and waviness technology, applied in the field of aircraft measurement, can solve the problems of poor accessibility, complex composition, large volume, etc., and achieve the effect of simple structure, convenient operation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

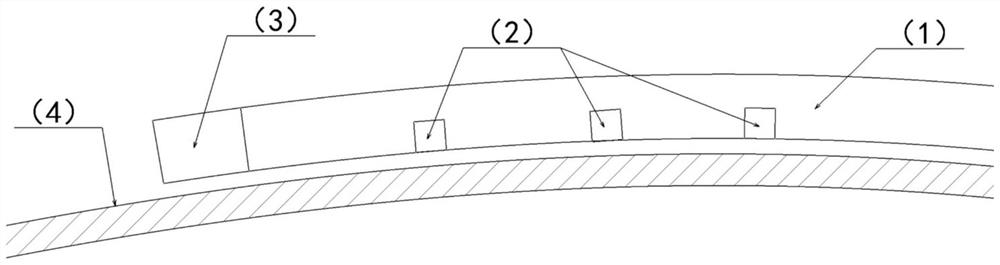

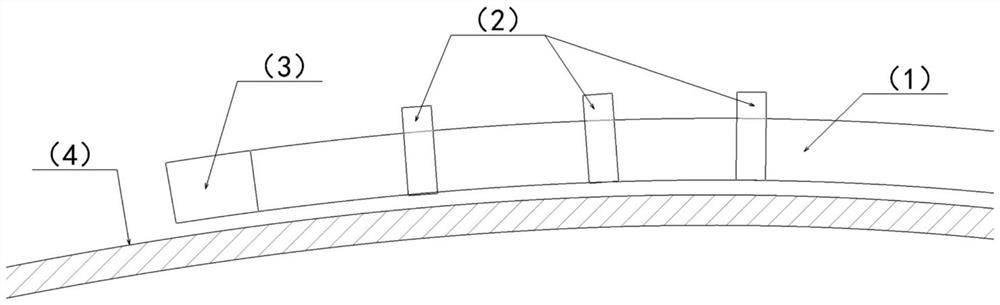

[0024] A waviness measuring device, comprising a spline 1, a sensor 2 and a data transmission and power supply module 3, a number of sensors 2 are distributed on the spline 1 at certain intervals, and the data transmission and power supply module 3 is connected to all sensors 2 for data transmission ;Sensor 2 is a distance sensor, and the detection direction is below spline 1.

[0025] Further, spline 1 is a strip-like structure.

[0026] Further, the spline 1 is a material with suitable elasticity and rigidity, such as a polyurethane rubber strip.

[0027] Further, the sensor 2 is a laser sensor or an infrared sensor.

[0028] Further, the probes of all sensors 2 are flush with the bottom of spline 1.

[0029] Further, the sensor 2 is connected to the spline 1 in a fixed installation manner, specifically, the sensor 2 is em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com