Coupling scheduling model and coupling scheduling method for intelligent manufacturing workshop production and calculation tasks

A computing task, intelligent manufacturing technology, applied in computing models, manufacturing computing systems, biological models, etc., can solve problems such as target damage, and achieve the effect of optimizing the completion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] The present invention will be further described below in conjunction with drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not as limitations of the present invention.

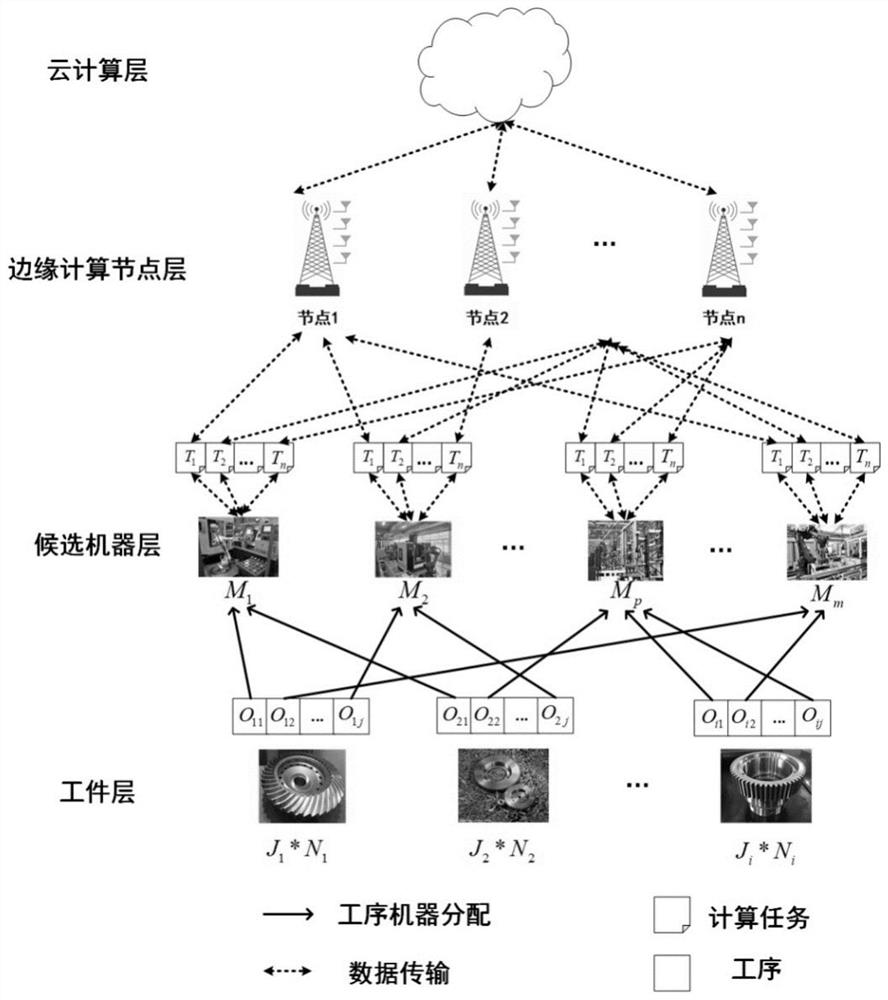

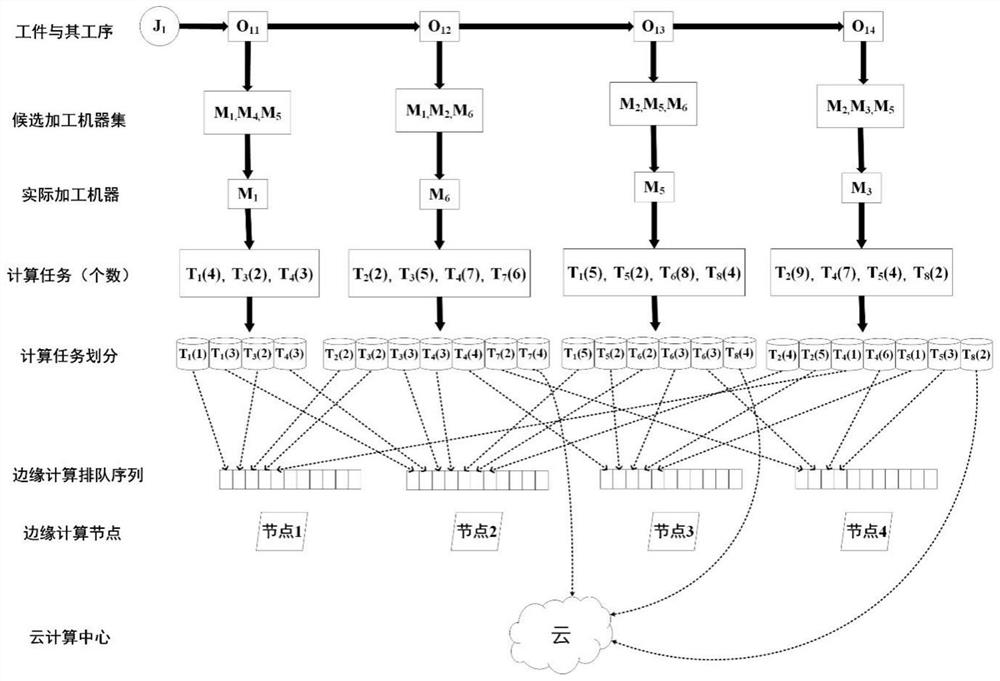

[0124] Such as figure 1 Shown is the frame diagram of the intelligent manufacturing workshop system. The intelligent manufacturing workshop system is mainly composed of four layers, which are workpiece layer, processing machine layer, edge computing layer and cloud computing layer. The workpiece layer is composed of workpieces that need to be processed in the workshop. Each workpiece needs to go through a series of processing procedures to complete, and different workpieces need to be processed in different numbers. J in the figure i represents the i-th workpiece, N i Indicates the processing quantity of the workpiece, O ij Indicates the j-th process of the i-th workpiece, and each process has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com