Display panel and manufacturing method thereof

A display panel and display area technology, which is applied in the direction of instruments, electrical components, circuits, etc., can solve the problems of poor performance of red light and green light, difficulty in full-color display, and low product yield, so as to simplify the manufacturing process and ensure The effect of product yield and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

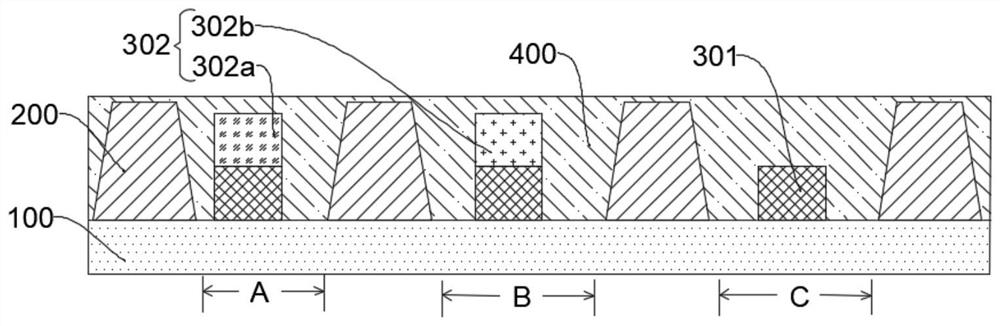

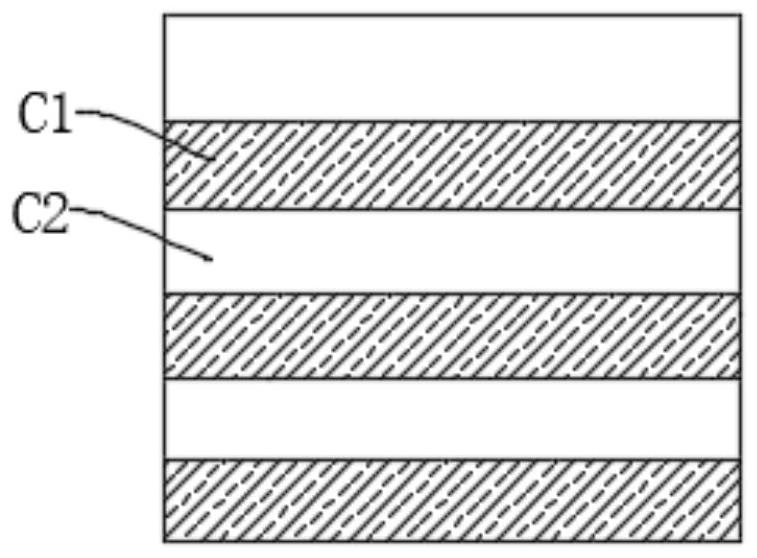

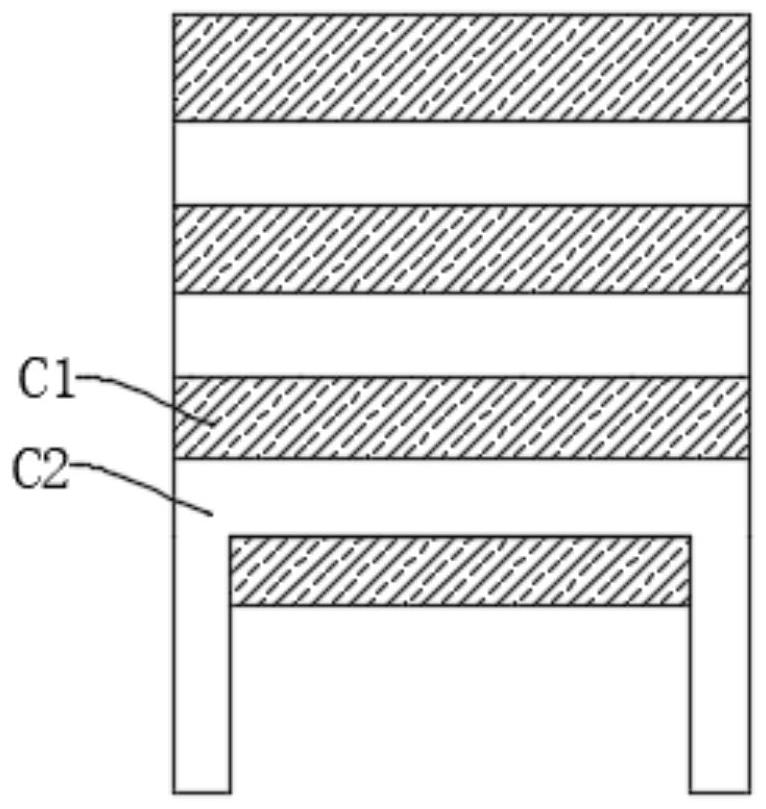

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the application with reference to the drawings in the embodiments of the application. Apparently, the described embodiments are only some of the embodiments of the application, not all of them. Based on the embodiments in this application, all other embodiments obtained by those skilled in the art without making creative efforts belong to the scope of protection of this application.

[0036] With the development of display technology, traditional human liquid crystal display technology is gradually unable to meet the needs of the market in terms of color rendering, luminous efficiency, and flexibility. The new generation of lighting and display technology has become a hot spot for investment and research. Among them, micro light-emitting diodes (micro light-emitting diodes, Micro-leds) have relatively smaller pixel sizes, and are suitable for indoor screens and small-sized di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com