Pressure bulkhead

A technology of pressure chamber and laminated body, applied in the direction of fuselage bulkhead, fuselage, weight reduction, etc., can solve the problems of increase in mass and volume, and achieve the effect of weight reduction, cost reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

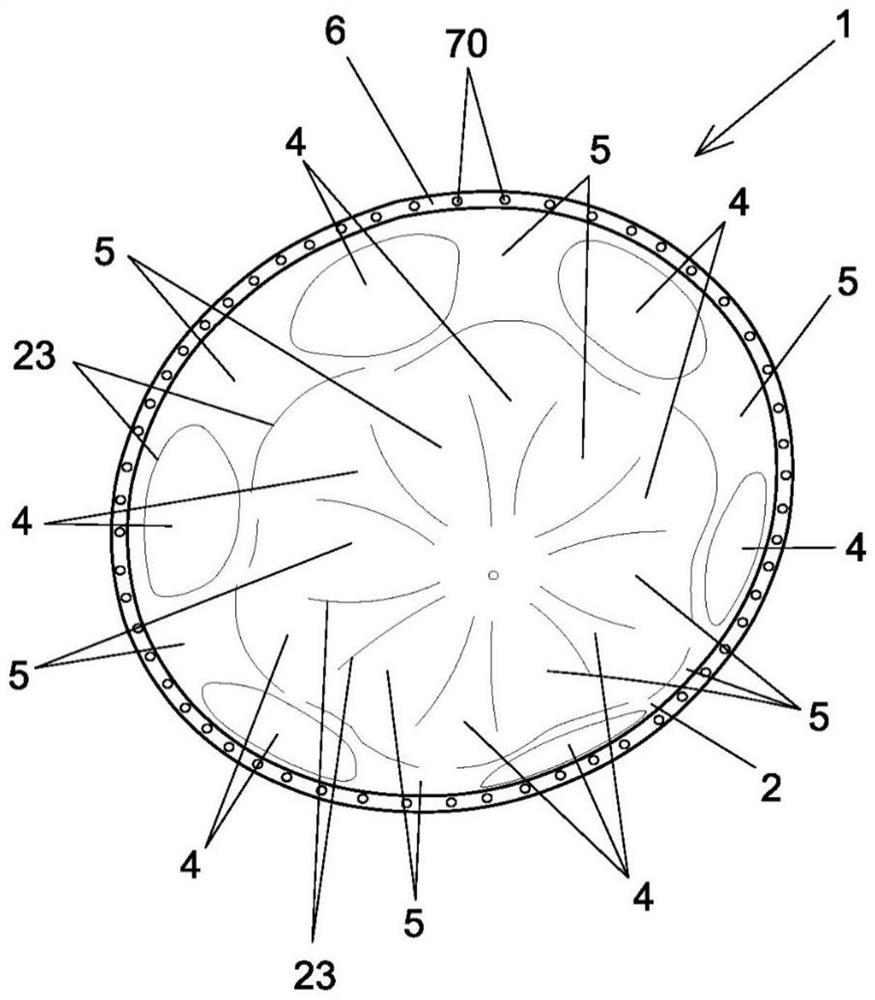

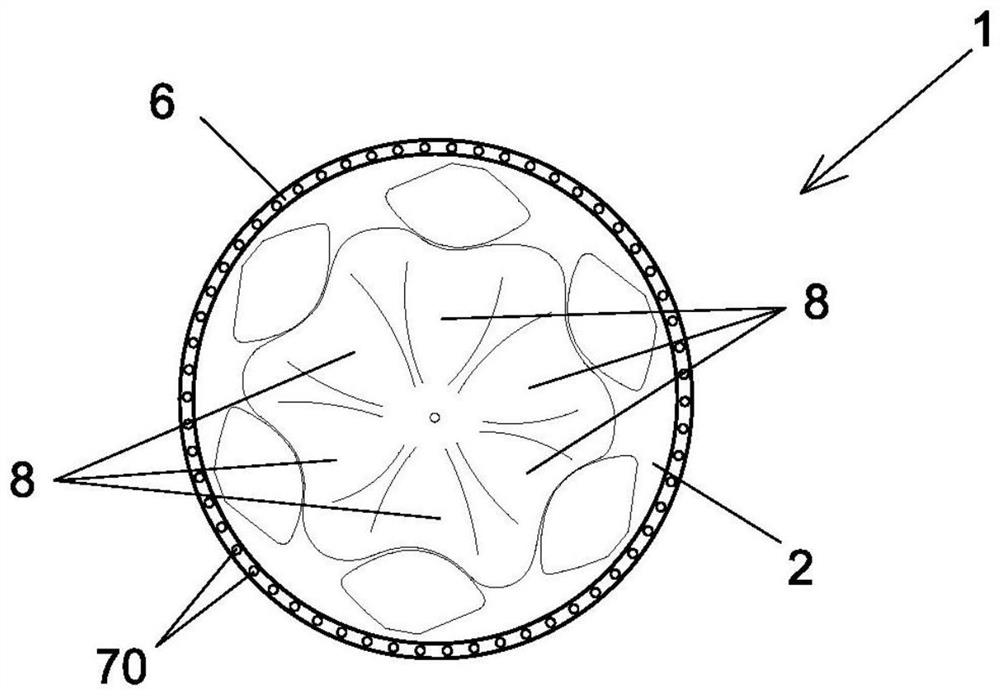

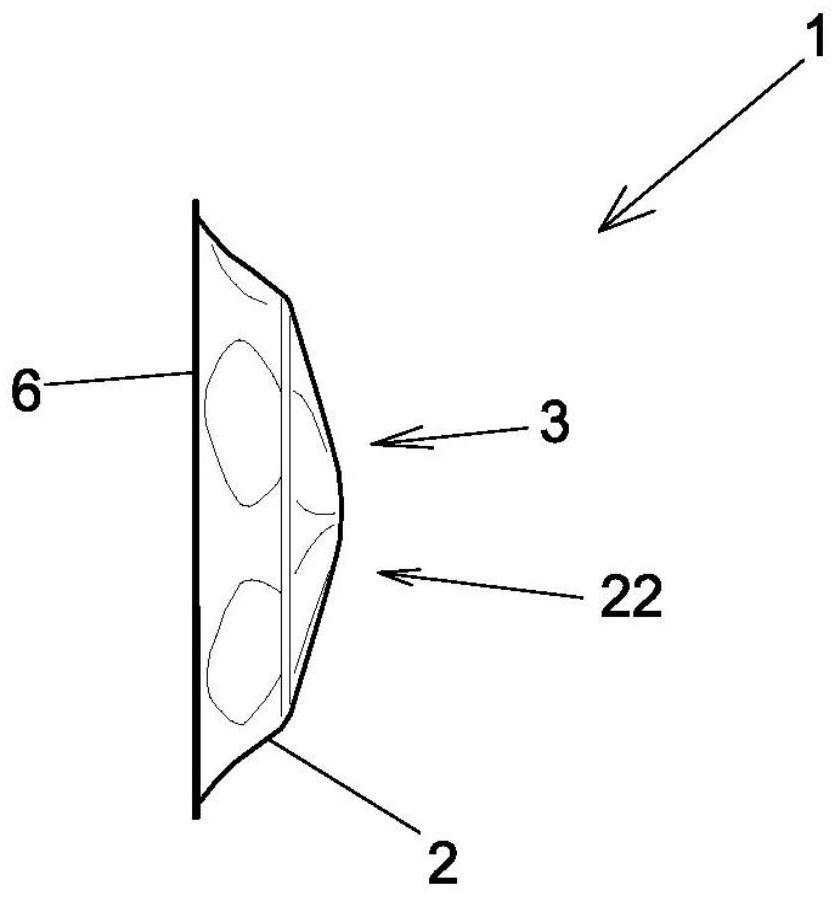

[0017] The pressure bulkhead 1 of the present invention comprises:

[0018] - a laminate 2 made of composite material having a polymer matrix in a laminated arrangement reinforced with continuous fibers,

[0019] - the overall raised portion 3 of the laminate 2 (see image 3 ), the raised portion 3 extends along the laminate surface 22,

[0020] - concave relief 4 and convex relief 5 arranged alternately on the laminate 2 (see figure 1 ), defining a reinforcement area 23 that changes from convex to concave and acts as a reinforcement (the reinforcement areas are shown with thin lines in the drawings, but they are not actually physical edges, they are only marked for a better understanding of the present invention invention).

[0021] - the concave relief 4 and the convex relief 5 have a maximum angular width of 180 degrees to prevent negatives in the production mold and to facilitate demolding; and

[0022] - a rigid interface 6 embedded in the laminate 2 for fixing the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com