Mashed taro strip frying equipment for food processing

A technology of food processing and taro paste, which is applied in metal processing, oil/fat baking, etc., can solve the problems of low cutting efficiency and uneven cutting of taro paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

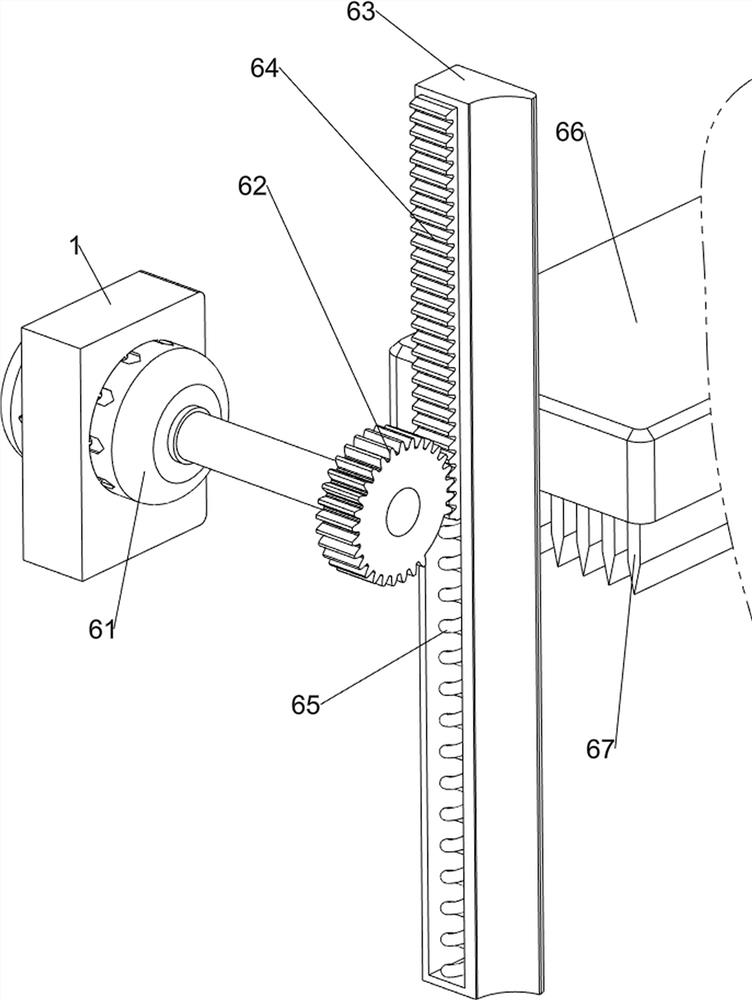

[0035] A kind of fried taro paste equipment for food processing provided by the invention, refer to Figure 1 to Figure 3 , including frame 1, hot oil frame 2, drain frame 3, grip rod 4, material storage frame 5, first support column 51, half-plate cylinder baffle plate 52 and first rotating rod 53, the lower part of the right side of frame 1 A hot oil frame 2 is placed, and two leak frames 3 are placed in the hot oil frame 2, and the left side of the upper part of the two leak frames 3 is provided with a handle bar 4, and the left side of the inside of the frame 1 is provided with two first support columns 51. A material storage frame 5 is arranged between the right sides of the two first support columns 51, and the front and rear sides of the lower part of the material storage frame 5 are rotatably provided with a first rotating rod 53. Between the two first rotating rods 53 A half-plate cylinder material baffle 52 is arranged between, and the half-plate cylinder material ba...

Embodiment 2

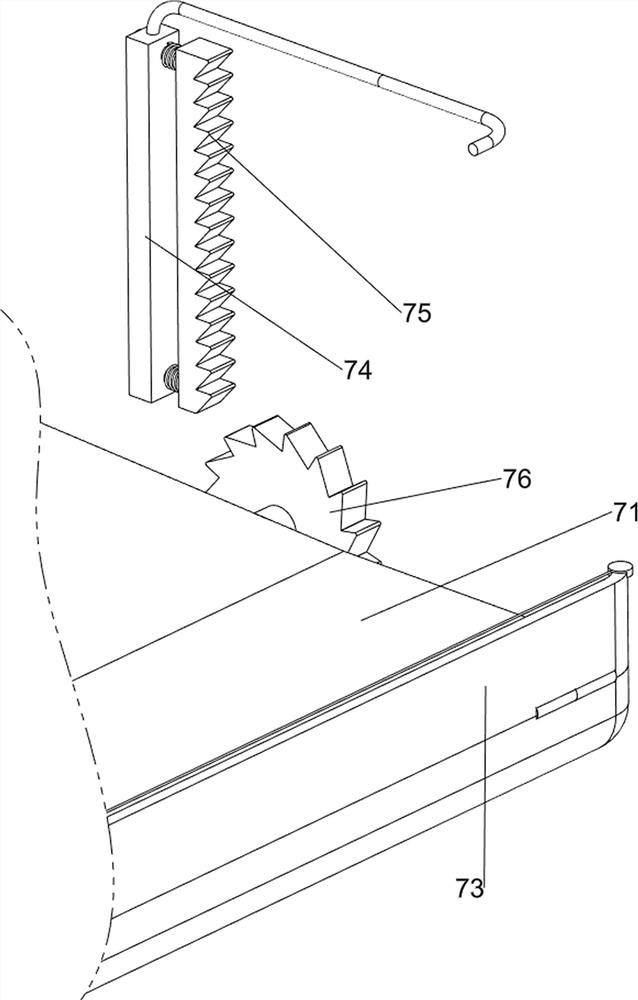

[0039] On the basis of embodiment 1, refer to Figure 4 to Figure 8 , also includes an unloading mechanism 7, the unloading mechanism 7 includes an unloading plate 71, a second rotating rod 72, a baffle plate 73, a first pressing rod 74, a ratchet rack 75 and a ratchet gear 76, and the front and rear of the frame 1 inner middle part Both sides are provided with second rotating rods 72, between the two second rotating rods 72, a discharge plate 71 is rotatably provided, the right side of the discharge plate 71 is hingedly connected with a baffle plate 73, and the left side of the discharge plate 71 The rear side is provided with a ratchet gear 76, and the rear side of the knife rest 66 is provided with a first pressing bar 74, and the first pressing bar 74 is slidably connected with the material storage frame 5, and the right side of the first pressing bar 74 bottom is A ratchet bar 75 is provided in a side sliding manner, an elastic member is provided between the ratchet bar 7...

Embodiment 3

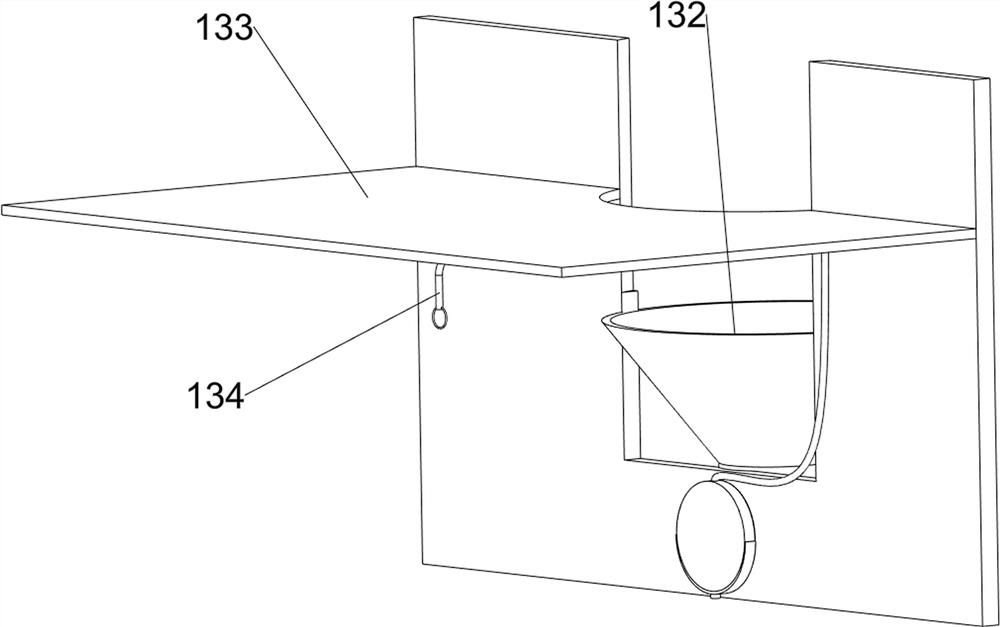

[0044] On the basis of embodiment 2, refer to figure 2 , Figure 9 and Figure 10 , also includes a blanking mechanism 10, the blanking mechanism 10 includes a hopper 101, a third cover plate 102, a wedge block 103, a third slide rail 104, a support spring 105, a second rack 106, a third rotating rod 107, a first Two support plates 108 and spur gears 109, the upper right side inside the frame 1 is provided with a lower hopper 101, the rear side of the bottom of the lower hopper 101 is provided with a second support plate 108, and the second support plate 108 is rotatably provided with a third rotation. Rod 107, the left side of the third rotating rod 107 is provided with a spur gear 109, the right side of the third rotating rod 107 is provided with a third cover plate 102, and the third cover plate 102 cooperates with the lower hopper 101, and the lower side of the lower hopper 101 A third slide rail 104 is provided at the bottom of the bottom, and a second rack 106 is slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com