Bending device for aluminum alloy ingot machining and forming

A processing forming and bending device technology, which is applied in the field of aluminum alloy ingot processing, can solve the problems of manual pressing and low bending efficiency, and achieve the effects of avoiding offset, improving bending efficiency, and improving bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

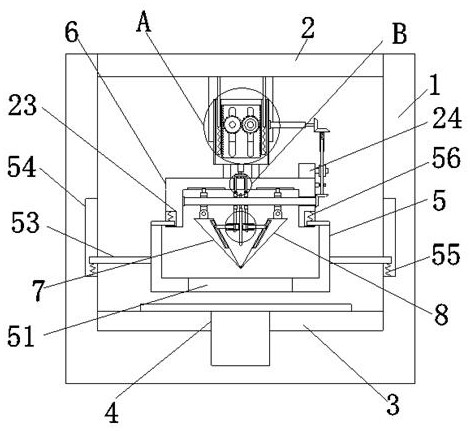

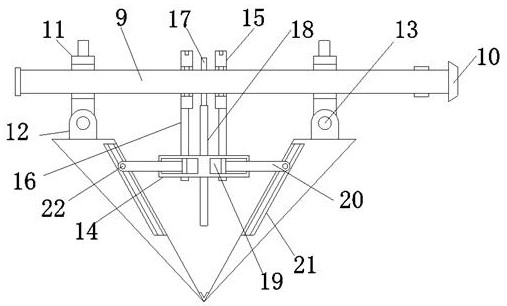

[0033] Example one, by Figure 1 to Figure 7 Given, the present invention includes a support frame 1, the top end of the support frame 1 is provided with a horizontal plate 2, the inner bottom end of the support frame 1 is provided with a bending table 3, and the bottom end of the bending table 3 and the support frame 1 is provided with a connecting Through the bending groove 4, the upper part of the bending table 3 is provided with a pressing plate 5, the upper part of the pressing plate 5 is connected with a mounting plate 6, and the upper part of the mounting plate 6 is connected with the horizontal plate 2 through a height adjustment mechanism, and the mounting plate 6 is inverted. The U-shaped structure, the lower part of the mounting plate 6 is provided with a bending plate 1 7 and a bending plate 2 8, the bottom ends of the bending plate 1 7 and the bending plate 2 8 are connected by hinges, and the bending plate 1 7 It is connected with the bending plate 2 8 by a spaci...

Embodiment 2

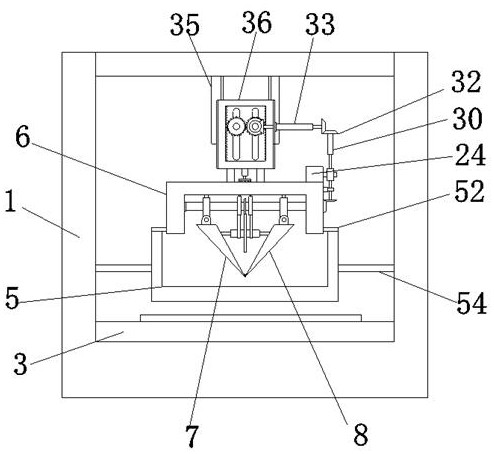

[0036] Embodiment 2, on the basis of Embodiment 1, by figure 1 , figure 2 , image 3 and Figure 7 Given, the spacing adjustment member includes an internal thread groove 19, a T-shaped screw 20, a sliding groove 21 and a sliding rod 22, and a sliding groove 21 is provided on the adjacent side of the bending plate 7 and the bending plate 2 8, and the rotating cylinder 14 The inner wall is symmetrically provided with an internal thread groove 19, the inner thread of the internal thread groove 19 is threadedly connected with a T-shaped screw 20, one end of the T-shaped screw 20 extends to the interior of the sliding groove 21, and the T-shaped screw 20 is provided with the sliding groove 21. The sliding rod 22 is slidably connected, the driver includes a motor 24, a turbine 25, a worm 26, a bevel gear 27 and a transmission part, the top of the mounting plate 6 is provided with a motor 24, the output shaft of the motor 24 is connected with a turbine 25, and the mounting plate ...

Embodiment 3

[0038] Embodiment 3, on the basis of Embodiment 1, by figure 1 , figure 2 , Figure 5 and Image 6 Given, the height adjustment mechanism includes a fixed plate 35, a height adjustment frame 36, a bevel gear five 37, a slot 38, a rotating shaft 39, a gear three 40, gear teeth 41 and a connecting piece, and the bottom end of the horizontal plate 2 is provided with a fixed Plate 35, a height adjustment frame 36 is arranged on one side of the fixed plate 35, a rotating shaft 39 is symmetrically installed on the side wall of the fixed plate 35, a slot 38 is symmetrically opened on the height adjustment frame 36, and one end of the rotating shaft 39 runs through the slot 38 Inside, and one end of the rotating shaft 39 is provided with a gear three 40, two gear three 40 are meshed and connected, one of the rotating shaft 39 is connected with the transmission part, the inner wall of the height adjustment frame 36 is provided with gear teeth 41 at equal distances, and the gear thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com