Inertia friction welding device capable of freely adjusting inertia of flywheel

A friction welding and flywheel technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of unable to adjust the flywheel speed, slow downtime, frequent replacement of flywheels, etc., to save labor and time for replacing flywheel discs , increase the welding speed, reduce the use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

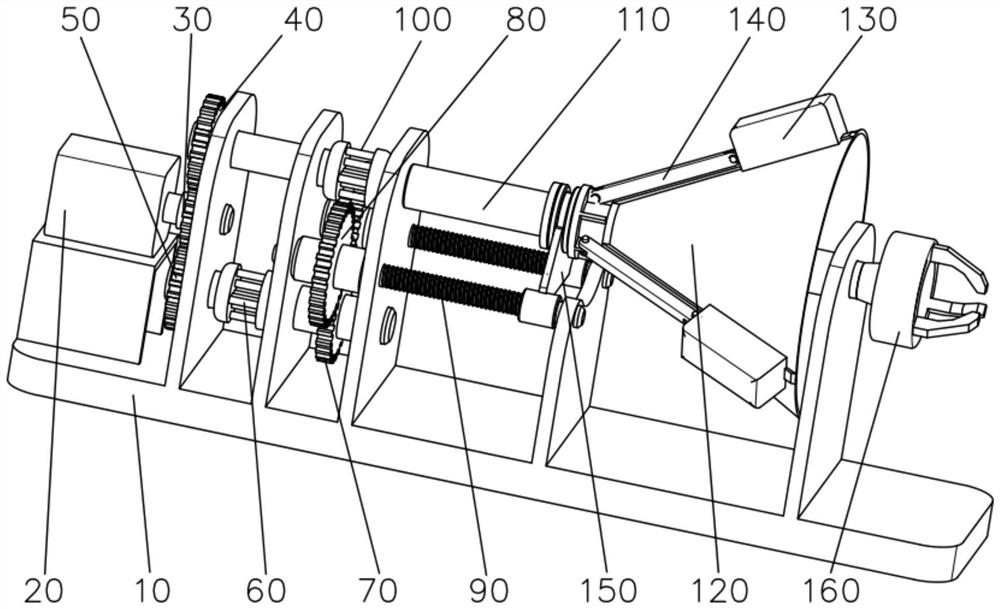

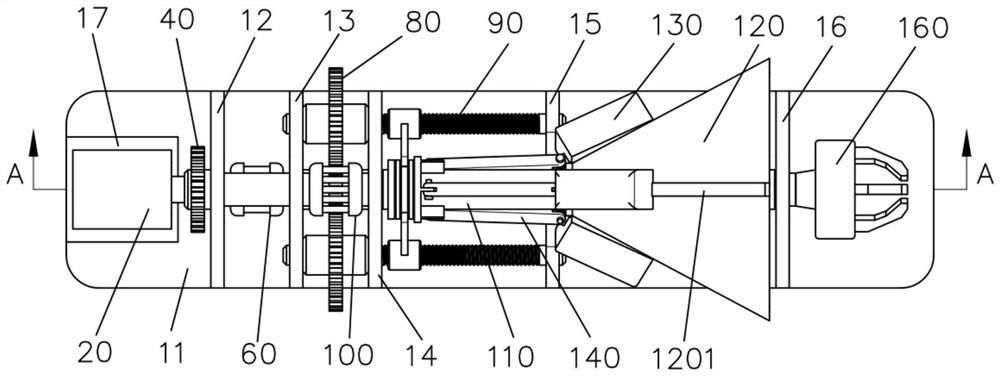

[0032] Such as Figure 1-8 As shown, an inertial friction welding device for freely adjusting flywheel inertia is characterized in that it includes a main body bracket 10, a motor 20, a driving gear 30, a first driven gear 40, a second driven gear 50, a lead screw clutch 60, The third driven gear 70, the fourth driven gear 80, the ball screw 90, the main shaft clutch 100, the main shaft 110, the conical flywheel disc 120, the mass slider 130, the connecting rod 140 and the driving assembly 150;

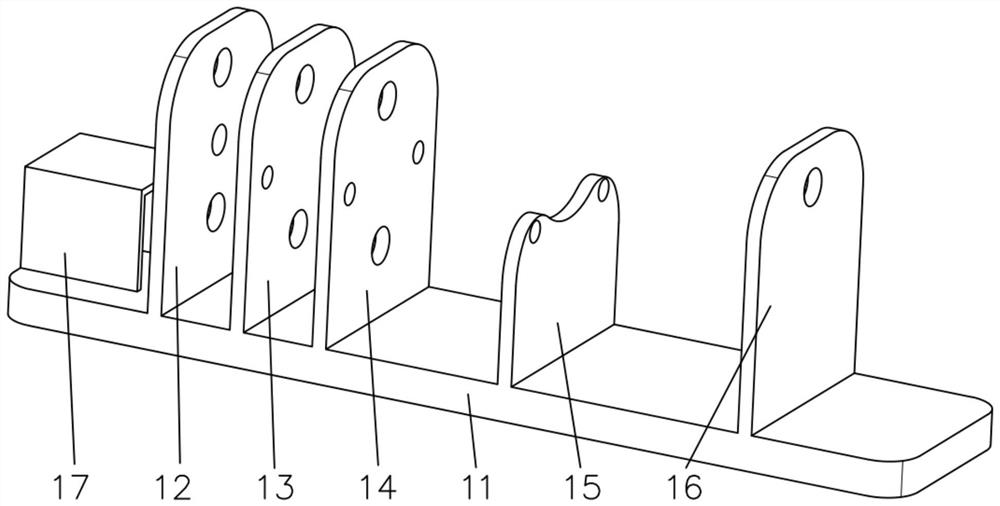

[0033] The main body bracket 10 includes a base 11, a gear bracket 12, a clutch bracket 13, a rotating shaft bracket 14, a screw bracket 15 and a main shaft bracket 16; the upper end surface of the base 11 is from left to right (such as figure 1 , figure 2 As shown), the gear bracket 12, the clutch bracket 13, the rotating shaft bracket 14, the lead screw bracket 15 and the main shaft bracket 16 are fixedly arranged in sequence;

[0034] The end of the output end of the motor 20 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com