New energy automobile front bumper assembly anti-sinking structure convenient to disassemble and assemble

A technology for a new energy vehicle and a front bumper is applied in the field of anti-sinking structure of a front bumper assembly of a new energy vehicle, and can solve the problem of difficult fixed connection of front bumper connecting rods, time-consuming and laborious disassembly and assembly of the front bumper, and front bumper. Problems such as easy offset and sinking, to achieve the effect of preventing extrusion offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

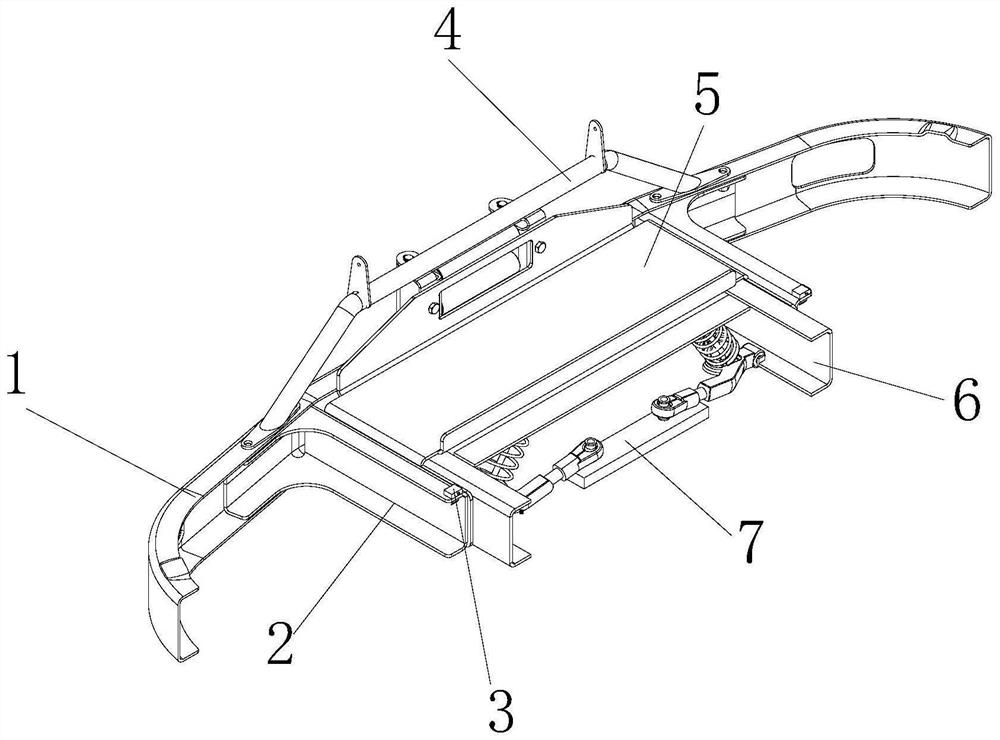

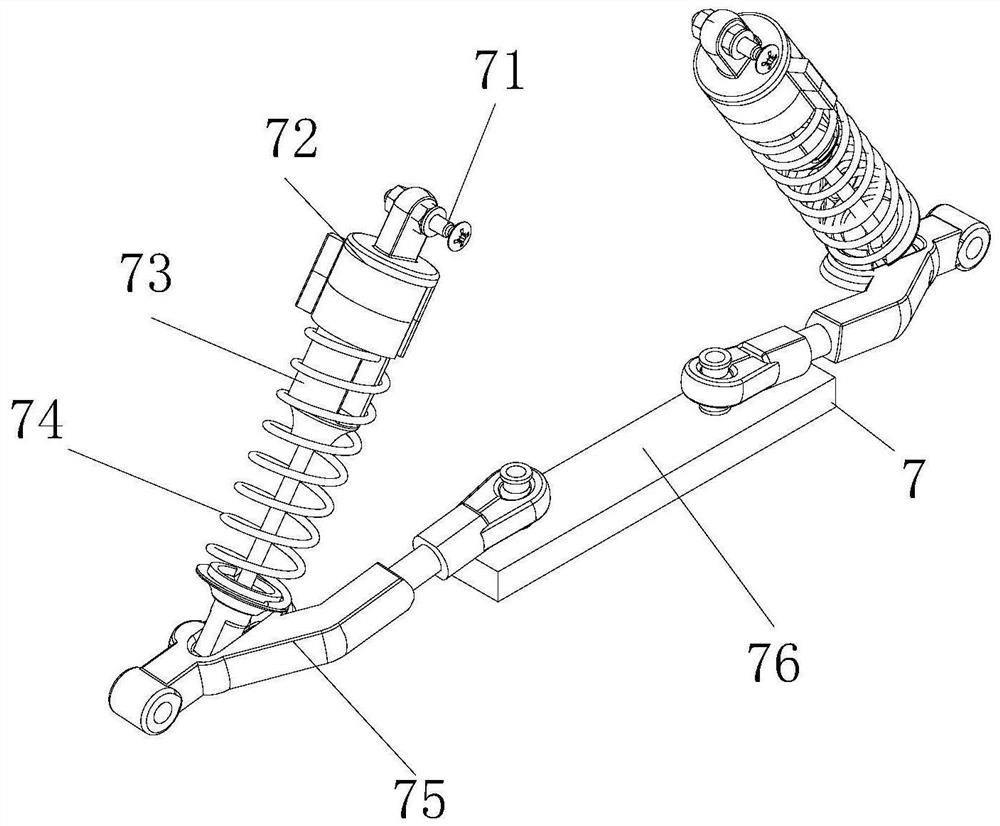

[0027] see figure 1 , the present invention provides an anti-sinking structure for the front bumper assembly of a new energy vehicle that is convenient for disassembly and assembly through improvement, including a front bumper 1, a support frame 2, a support beam 4, a connecting plate 5, a connecting rod 6, a positioning Mechanism 3 and supporting mechanism 7, the inner side of the front bumper 1 is embedded with a support frame 2, the upper end of the supporting frame 2 is provided with a positioning mechanism 3, the inner side of the connecting rod 6 is equipped with a supporting mechanism 7, the front bumper 1 and the bottom of the supporting beam 4 The front bumper 1 is fixed to the left end of the connecting plate 5, and the connecting rod 6 is arranged on the inner side of the connecting plate 5.

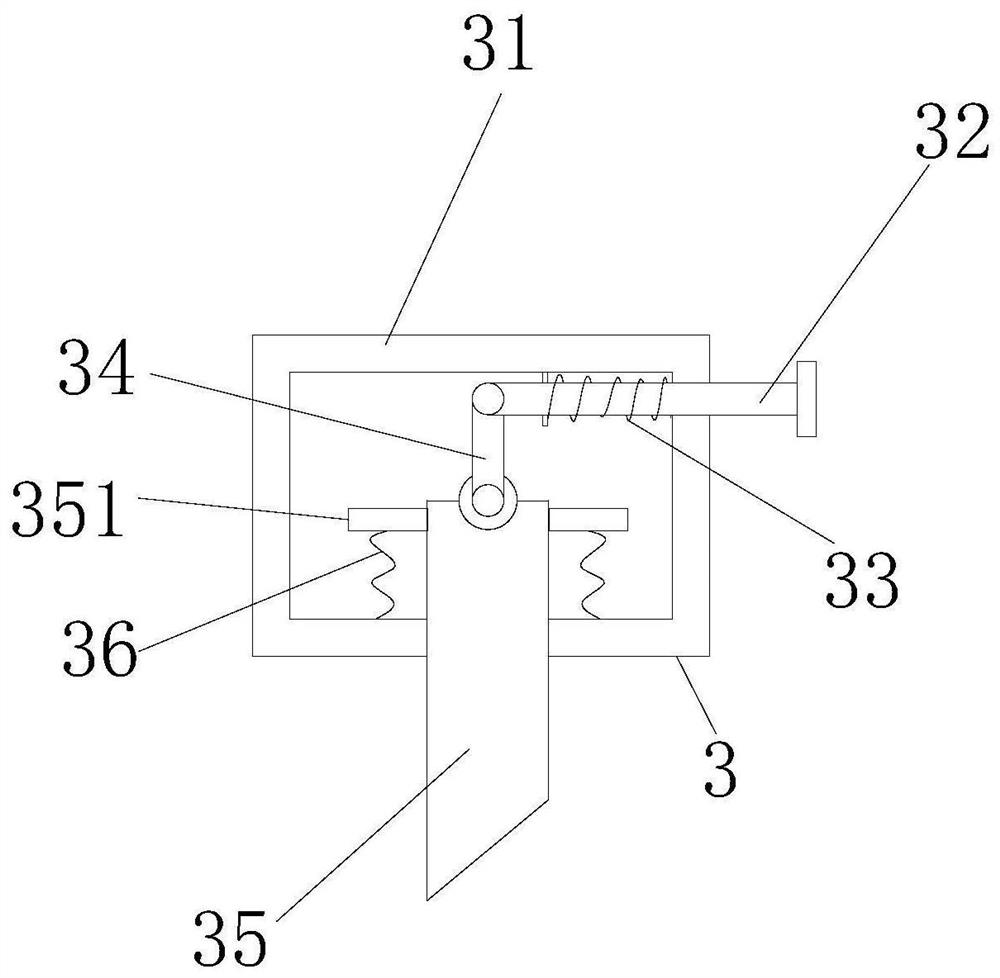

[0028] see figure 2 , the present invention provides an anti-sinking structure for the front bumper assembly of a new energy vehicle that is convenient for disassembly and a...

Embodiment 2

[0032] The present invention provides an anti-sinking structure for the front bumper assembly of a new energy vehicle that is convenient for disassembly and assembly through improvement. There are two compression springs 36, and the compression springs 36 are arranged opposite to each other along the left and right sides of the upper end of the limit rod 35. , which is beneficial to reset the limit rod 35, there are two positioning mechanisms 3, and the positioning mechanisms 3 are respectively located at the upper ends of the two supporting frames 2.

[0033] The present invention provides an anti-sinking structure for the front bumper assembly of a new energy vehicle that is convenient for disassembly and assembly through improvement, and its working principle is as follows;

[0034] First, before use, place the anti-sinking structure of the front bumper assembly of the new energy vehicle horizontally, so that the front bumper 1 can fix and support the structure;

[0035] Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com