Single-cavity three-mode ceramic waveguide resonator and filter

A waveguide filter and waveguide resonance technology, which is applied to waveguide-type devices, circuits, electrical components, etc., can solve the problem of difficulty in meeting the requirements of small size and high out-of-band suppression characteristics at the same time, so as to improve the out-of-band suppression characteristics and reduce the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

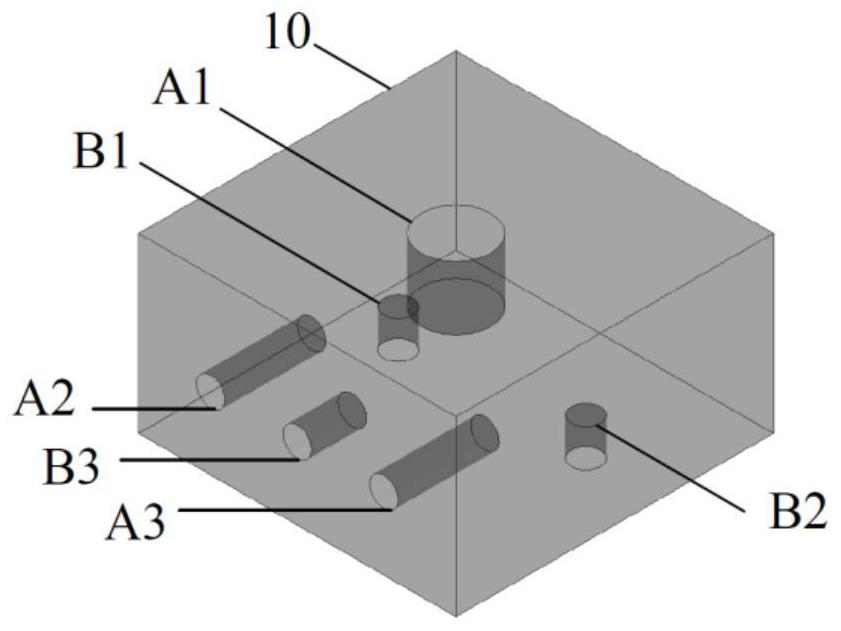

[0050] Such as figure 1 As shown, in one of the embodiments of the present invention, a single-cavity three-mode ceramic waveguide resonator is provided, including a ceramic waveguide resonator body 10 with a metal coating on the surface, three tuning blind holes on the surface of the body, and three Coupling blind vias.

[0051] The three tuning blind holes provided on the surface of the resonator body are tuning blind hole A1, tuning blind hole A2 and tuning blind hole A3, wherein the tuning blind hole A1 is located on the upper surface of the resonator, and the depth of the blind hole is adjustable. Adjust the depth of the tuning blind hole A1 to adjust the resonant frequency of the TE101 mode of the resonator. The tuning blind hole A2 and the tuning blind hole A3 are located on the side of the resonator. In this embodiment, the tuning blind hole A2 and the tuning blind hole A3 are located on the same side (based on figure 1 Look, it is located at the front of the four si...

Embodiment 2

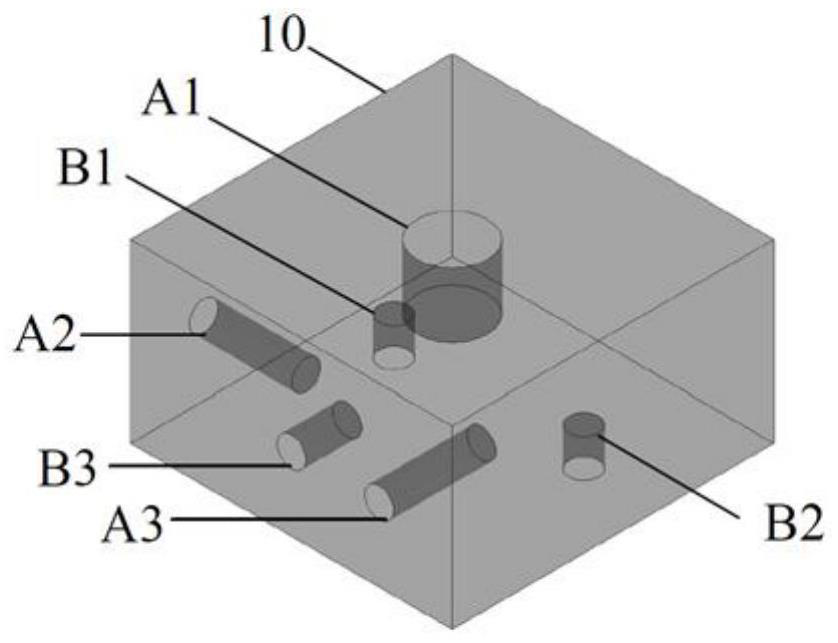

[0056] Such as figure 2 As shown, different from Embodiment 1, in this embodiment, the tuning blind hole A2 and the tuning blind hole A3 are located on adjacent sides (based on the attached figure 2 See, respectively located on the left side and the front side in the side), the coupling blind hole B3 can be located on any one of the four sides, and the depth of the coupling blind hole B3 is less than the tuning blind hole A2 and the tuning blind hole A3 arranged on the side. At this time, the coupling between the two quasi-TEM modes is negative coupling, and the resonator can be regarded as a capacitive CT structure, which will generate a transmission zero at the low frequency end of the passband.

Embodiment 3

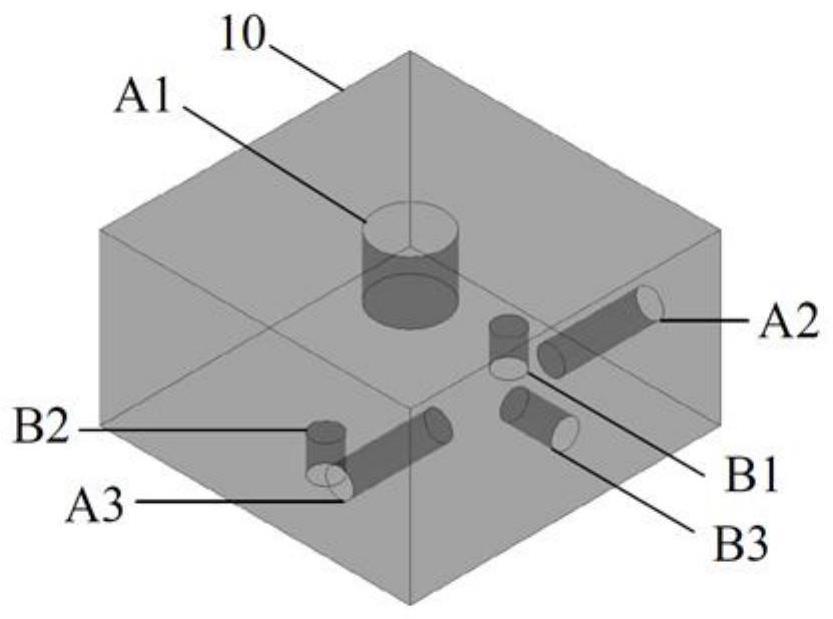

[0058] Such as image 3 As shown, different from Embodiment 1, in this embodiment, the tuning blind hole A2 and the tuning blind hole A3 are located on two opposite sides (based on the attached image 3 Look, they are respectively located at the front and rear of the sides), and the coupling blind hole B3 can be located at any one of the four sides. At this time, the coupling between the two quasi-TEM modes is negative coupling, and the resonator can be regarded as a capacitive CT structure, which will generate a transmission zero at the low frequency end of the passband.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com