Aloe extract processing equipment

A technology of aloe vera extract and processing equipment, which is applied in the direction of grain processing and the like, can solve the problems of wasting time, low processing efficiency, adverse effects of grinding effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

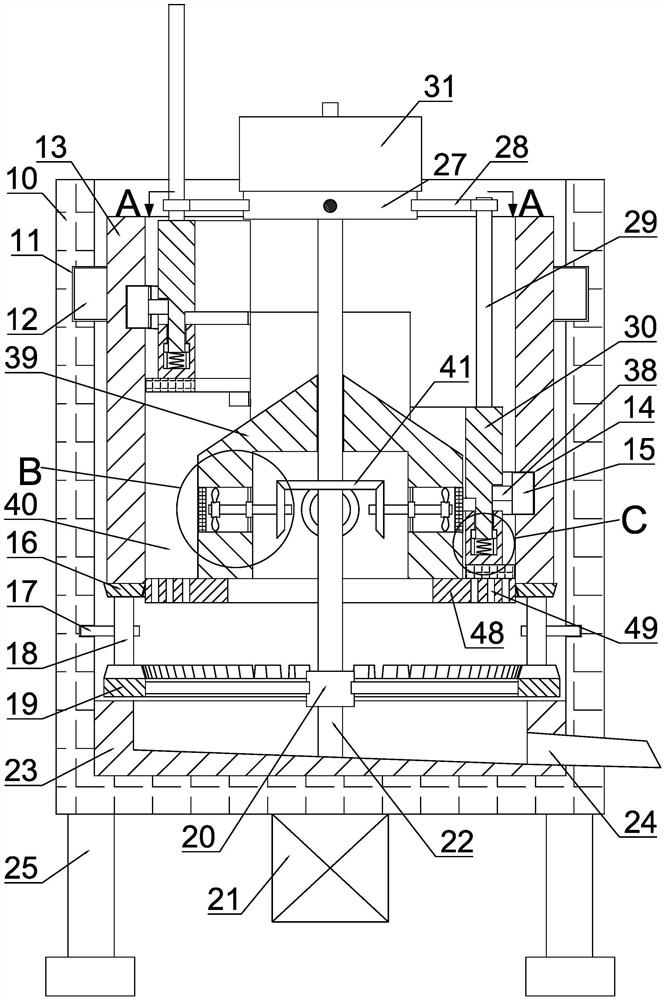

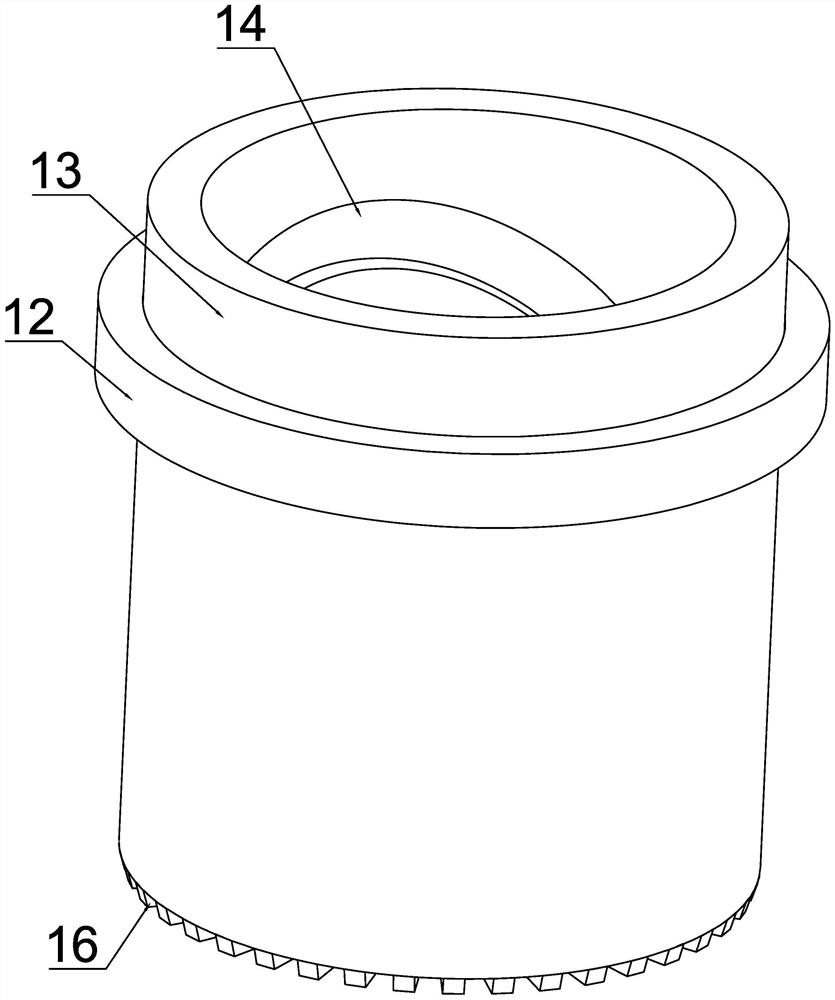

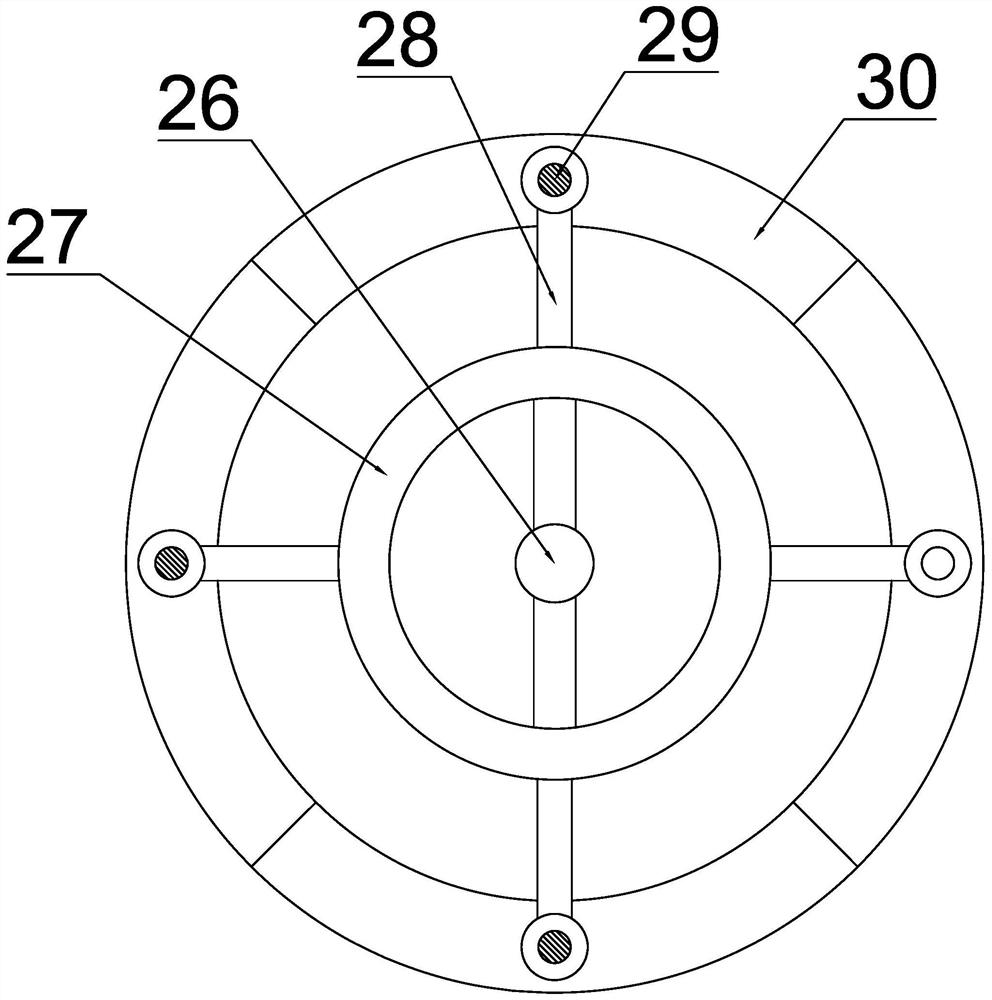

[0021] Such as figure 1 , figure 2 As shown, an aloe extract processing equipment includes a housing 10, and a centrifugal crushing mechanism is provided on the upper side of the casing 10. The centrifugal crushing mechanism is used to grind and squeeze the flesh of the aloe leaves to ensure that the flesh of the aloe leaves is fully crushed. The centrifugal crushing mechanism includes a support slide rail 11 on the upper side of the inner wall of the housing 10, a slip ring 12 is provided for sliding inside the support slide rail 11, an outer grinding box 13 is fixed on the inner side of the slip ring 12, and a processing slide is provided on the inner wall. Groove 14, four processing sliders 15 are slidably arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com