Bending pressure maintaining unit and product bending production line

A production line and product technology, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems of small production capacity, large space occupation, and complex structure, so as to reduce production costs, improve production efficiency, and meet beat requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

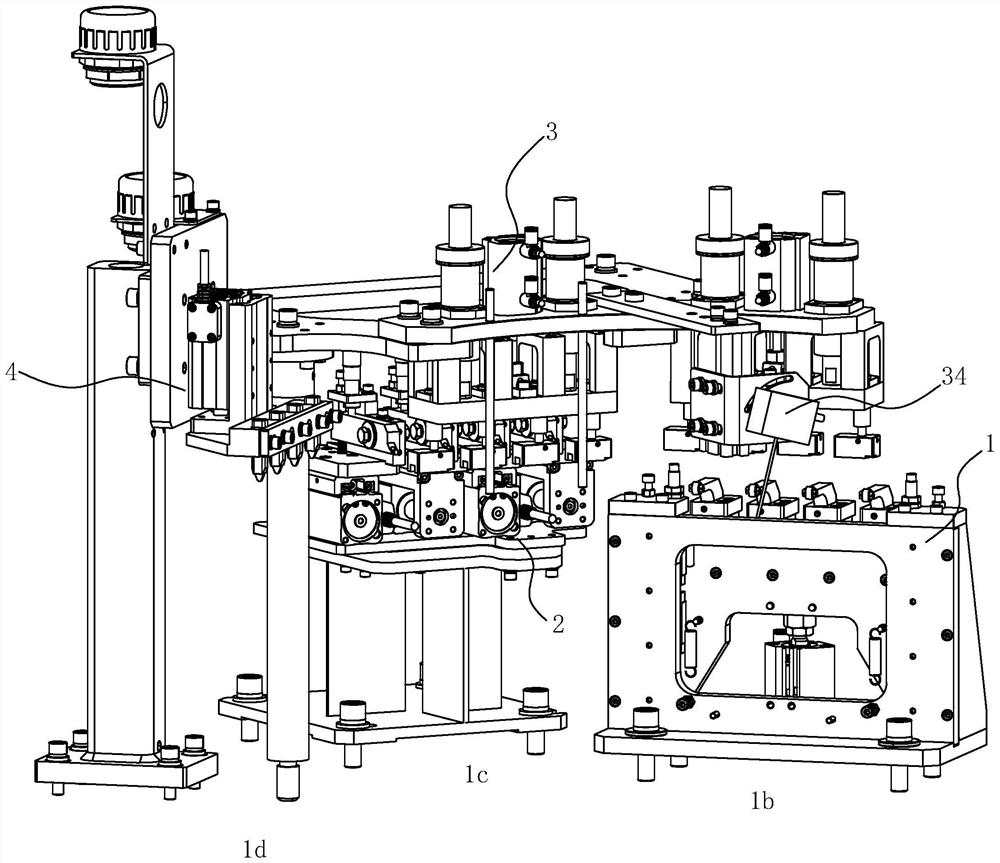

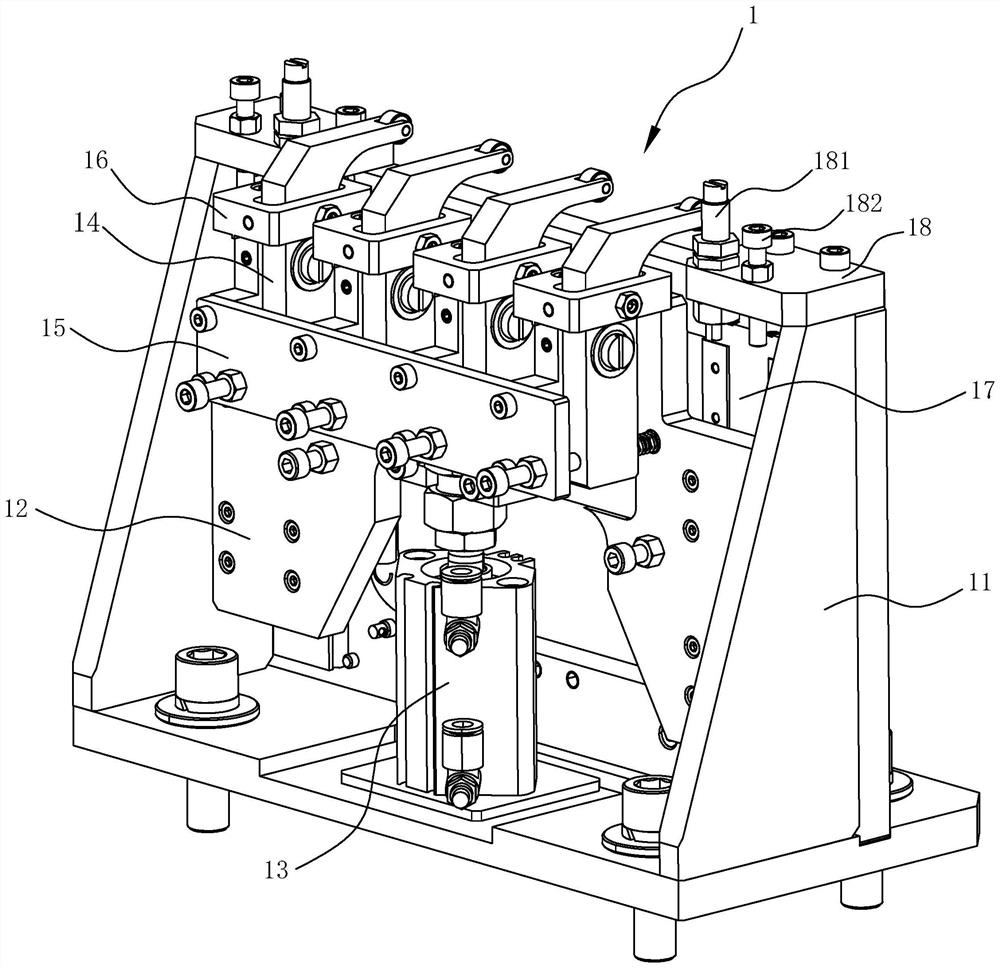

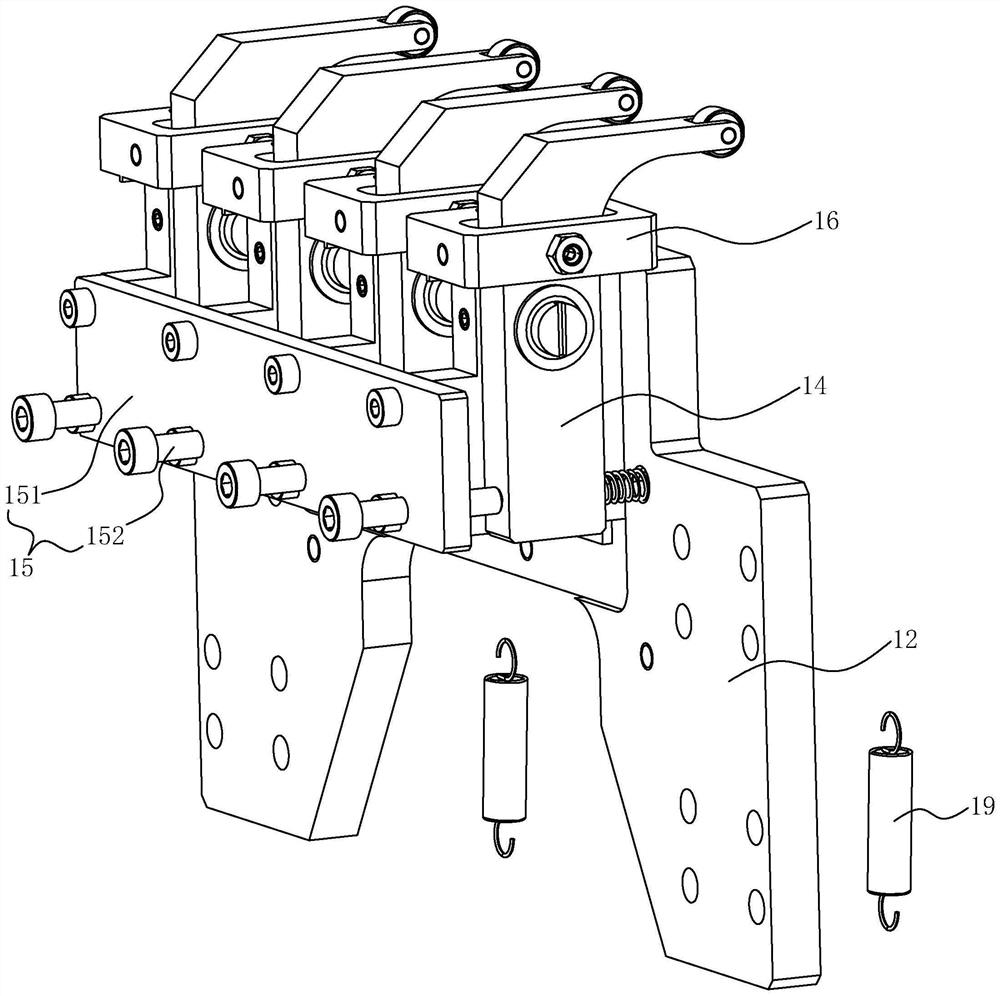

[0069] Depend on figure 1 As shown, this embodiment discloses a bending and pressure holding unit, including a first bending device arranged at the first bending station 1b, a second bending device arranged at the second bending station 1c, and The first bending station 1b and the second bending station 1c correspond to the pressing auxiliary bending device 3 and the holding device 4 arranged at the holding station 1d; with the assistance of the pressing auxiliary bending device 3, The first bending device is used to simultaneously bend the parts to be bent of multiple products (four products shown in the figure) in the first direction, and the second bending device is used to bend the parts that have been bent in the first direction The bending parts of the four products continue to bend in the second direction at the same time, and the first direction is perpendicular to the second direction; the pressure holding device 4 is used to simultaneously hold the bending parts of a...

Embodiment 2

[0091] Depend on Figure 12 , Figure 13 and Figure 17 Commonly shown, this embodiment discloses a product bending production line, including a multi-station turntable device 7 (which solves the problem of many bending stations caused by horizontal arrangement, simplifies the structure and meets the rhythm of the product process requirements), product conveying device 8, product feeding device 5, product unloading device 6, and the bending and pressure-holding unit disclosed in the first embodiment above.

[0092] Among them, the surrounding of the multi-station turntable device 7 is successively provided with a loading station 1a, a first bending station 1b, a second bending station 1c, a holding station 1d, a blanking station 1e, a first The empty station 1f, the optical fiber detection station 1g and the second empty station 1k have a total of eight stations; the multi-station turntable device 7 is used to drive a plurality of transfer tooling 74 for loading products to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com