Circumferential hole drilling, clamping and positioning tool

A positioning tooling and clamping technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of low circumferential hole processing efficiency and poor quality consistency, and meet the requirements of ensuring hole system processing, convenient combination, and improved processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

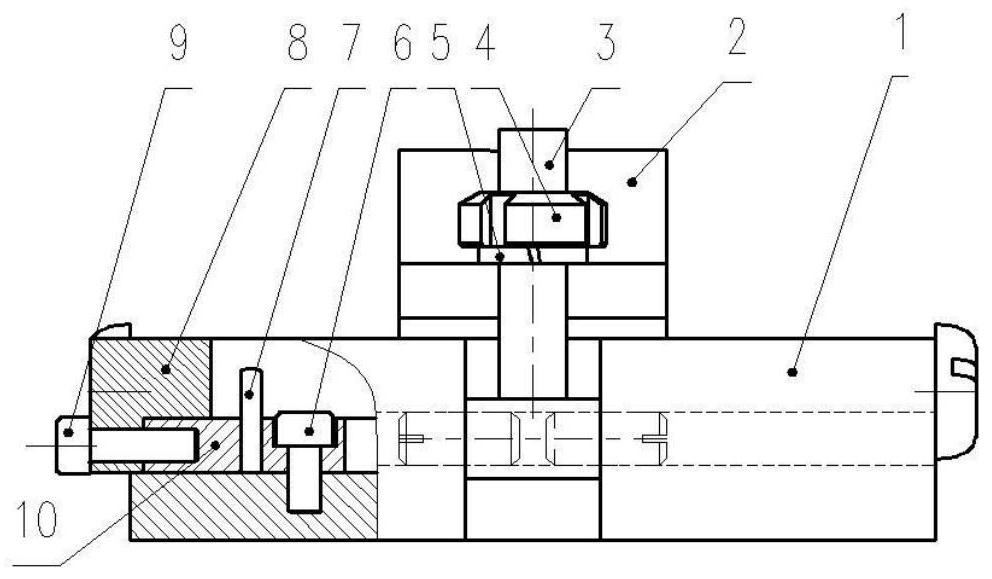

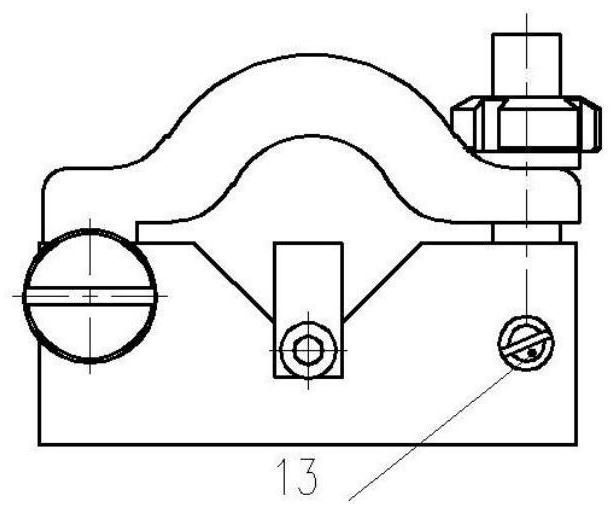

[0017] This embodiment proposes a peripheral hole drilling and clamping positioning tool, its structure is shown in Figure 2, mainly including a V-shaped base 1, a bottom plate 10, a pin 7, a positioning block 8, a pin shaft 11, a nut 12, and a cover plate 2. Column 3, stud 13, lock nut 4 and spring washer 5.

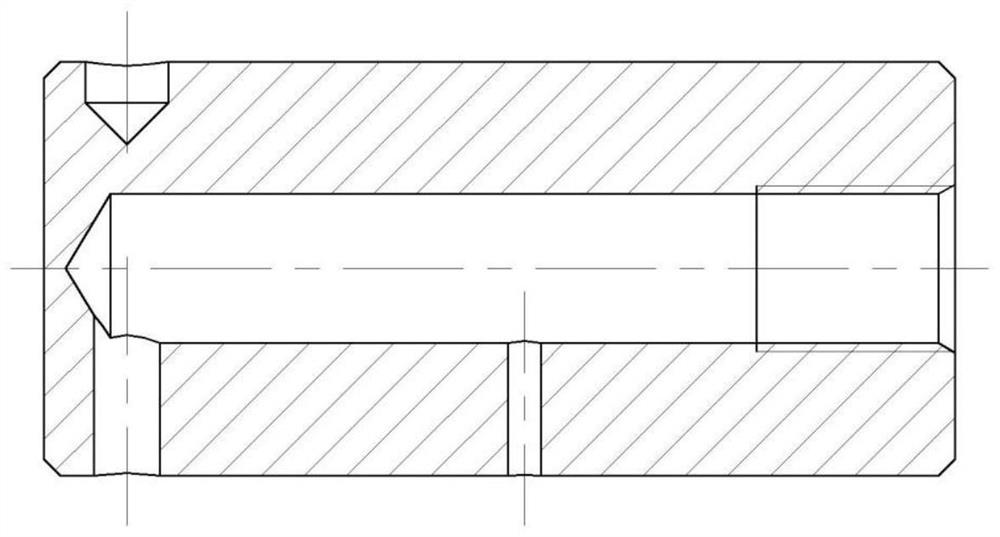

[0018] The V-shaped base 1 is processed with a V-shaped groove running through the length direction of the base. The bottom of the V-shaped groove has a square groove structure, and the two sides of the V-shaped groove are processed with a first pin hole and a second pin hole opposite to each other.

[0019] After the V-shaped base 1 is aligned, it is fixed on the machine tool table through the pressure plate. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com