Industrial robot automatic feeding and discharging system for numerical control machine tool

An industrial robot, automatic loading and unloading technology, applied in the direction of gear cutting machines, manufacturing tools, mechanical equipment, etc., can solve the problems of untimely discovery of gear quality problems, low degree of automation, low efficiency, etc., to avoid waste of production costs, automation High degree, reduce artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

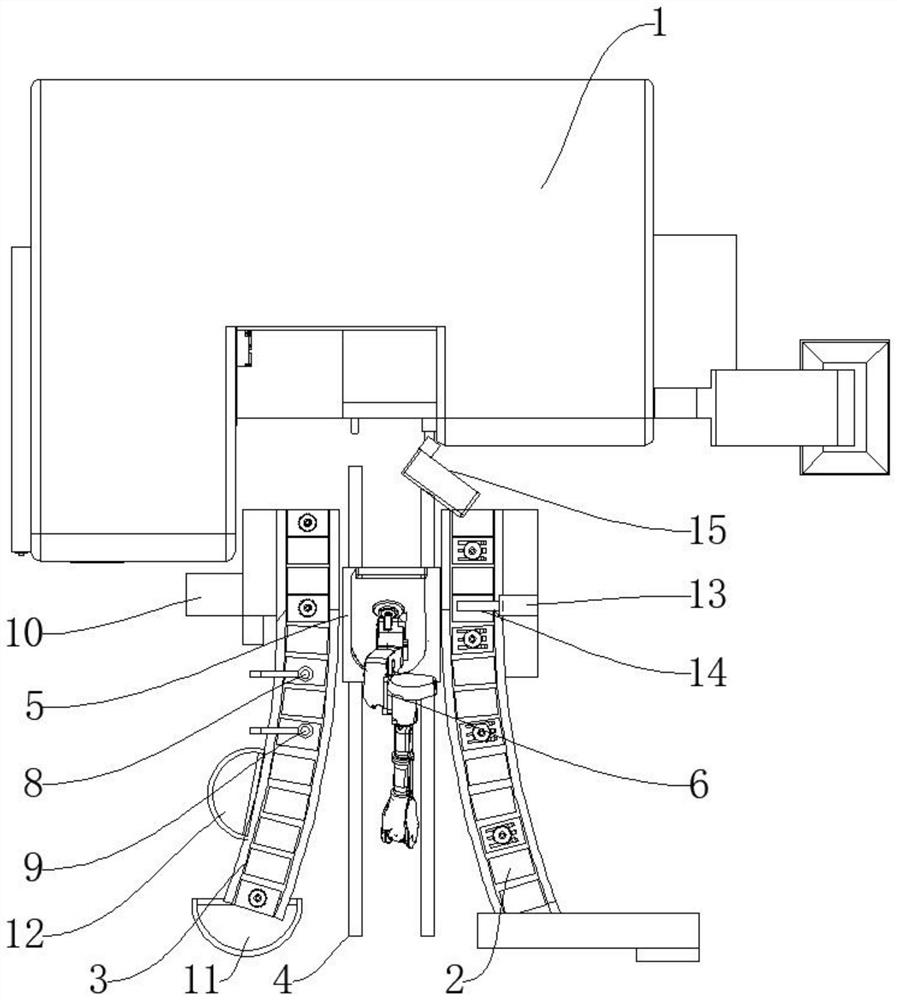

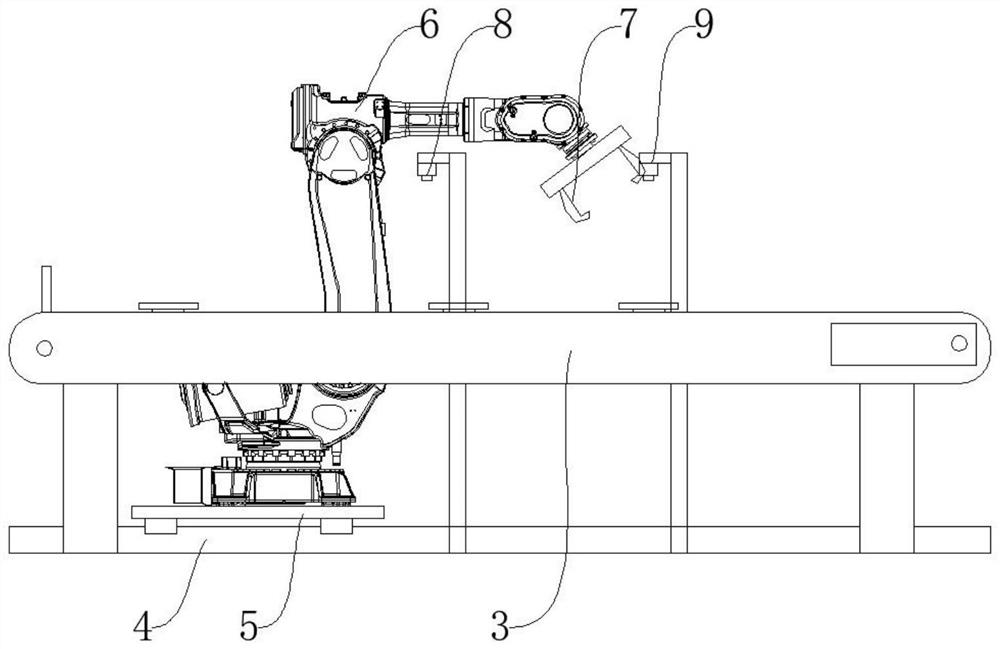

[0039] The following is attached Figure 1~4 The application is described in further detail.

[0040] The embodiment of the present application discloses an automatic loading and unloading system of an industrial robot for a numerically controlled machine tool.

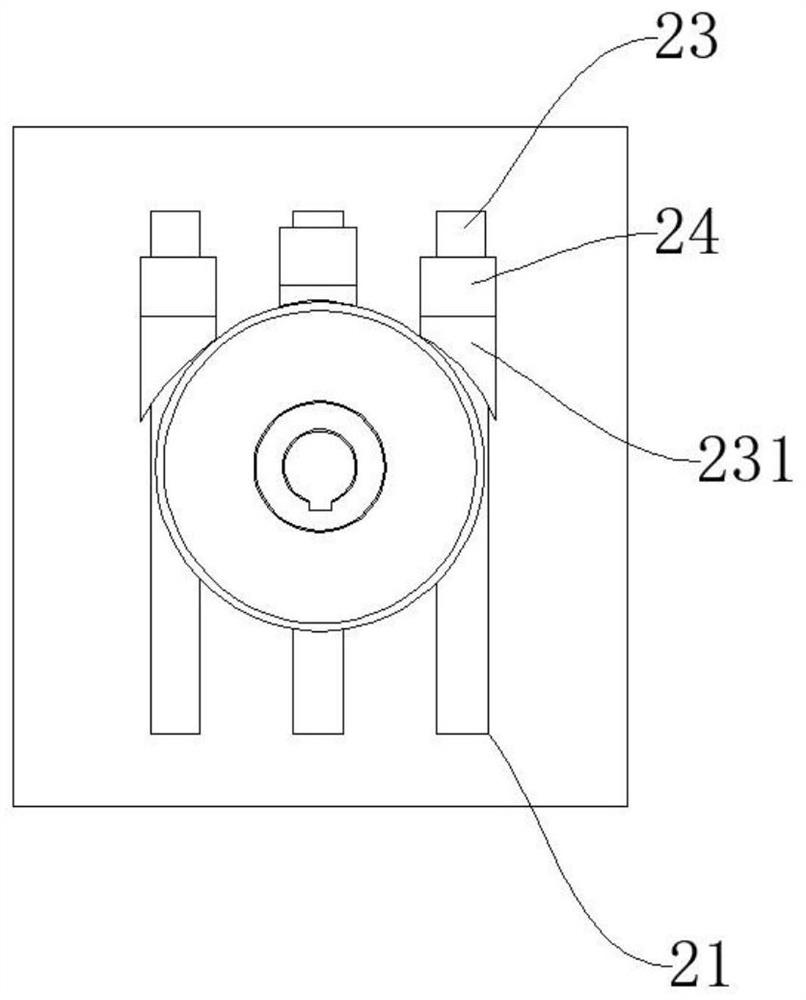

[0041] refer to Figure 1 ~ Figure 4 , an industrial robot automatic loading and unloading system for CNC machine tools, including a CNC machine tool body 1. The industrial robot automatic loading and unloading system includes a product circulation mechanism, an industrial robot loading and unloading mechanism, and a quality management module based on visual recognition. The product circulation mechanism includes Blank conveyor 2 for transmission gears, adjustable position positioning device for position positioning of gear blanks with different shapes, and semi-finished product conveyor 3 for transmission and processing of completed semi-finished products, blank conveyor 2 and semi-finished product conveyor 3 The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com