Device for controlling magnetic field orientation of composite material fiber, 3D printing device and 3D printing method

A 3D printing and composite fiber technology, applied in the field of 3D printing, can solve problems such as difficult processing, nozzle blockage, and no related reports, and achieve the effect of expanding the scope of processing and manufacturing processes and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are listed herewith, and are described in detail as follows in conjunction with the accompanying drawings:

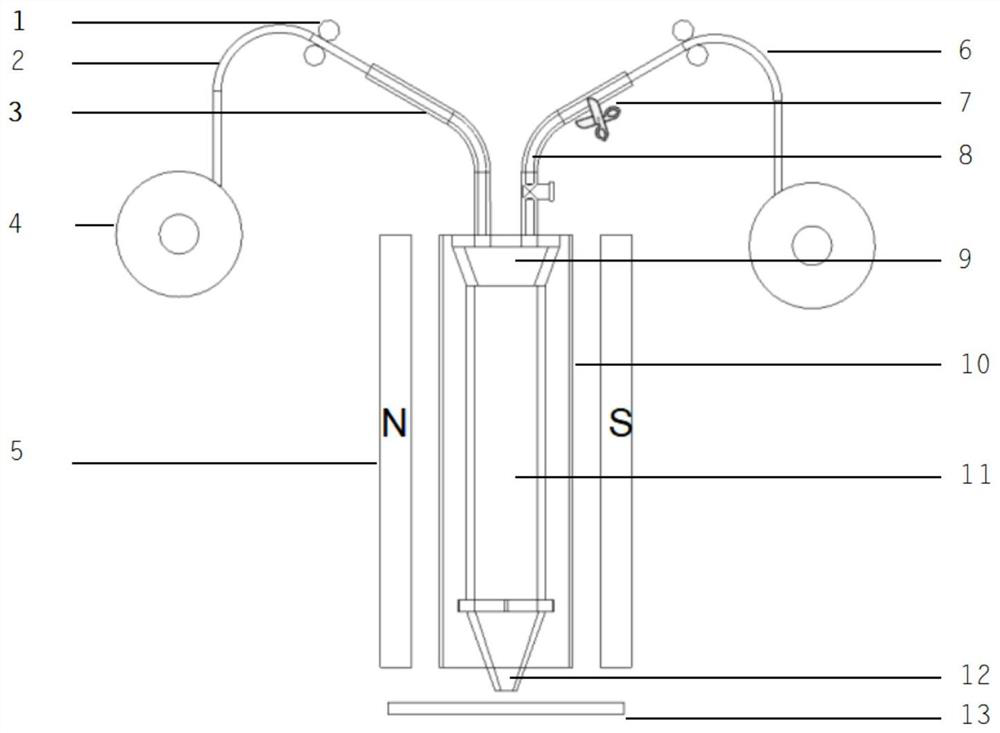

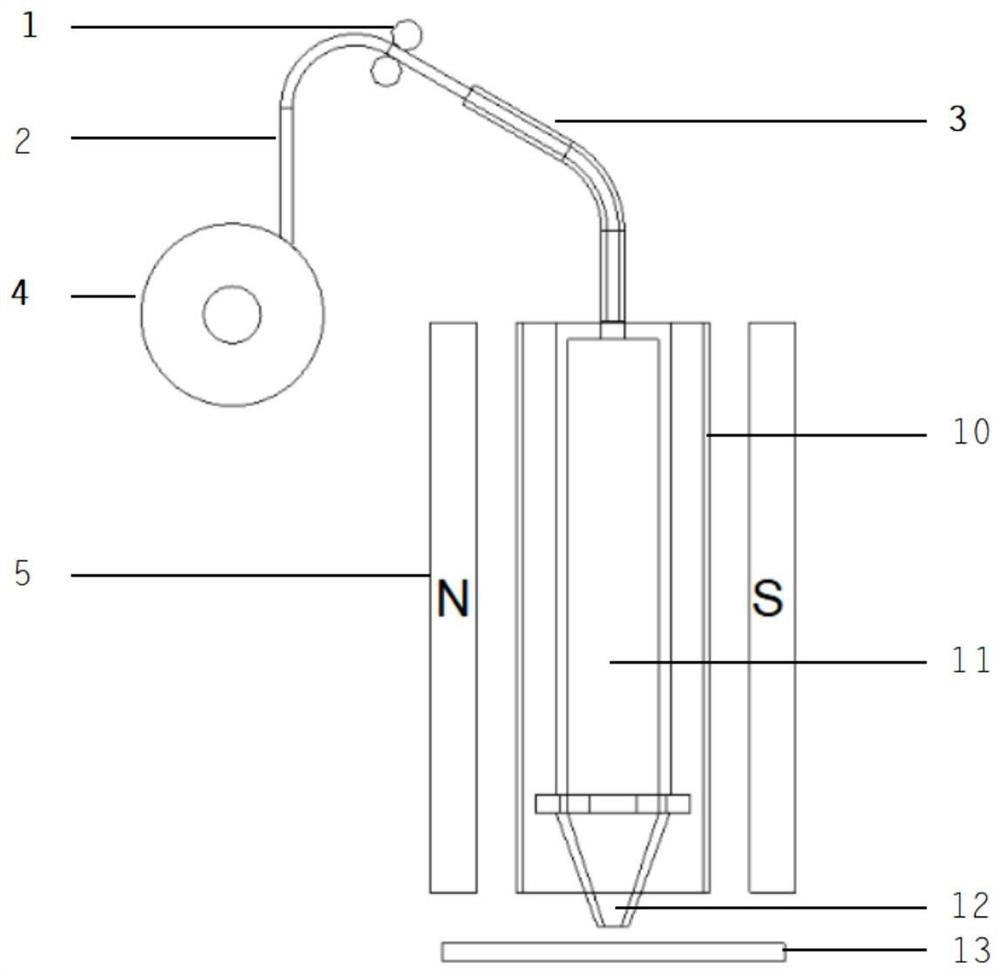

[0031] See Figure 1 to Figure 3 , a device for controlling the magnetic field direction of 3D printing composite fiber materials. A magnetic field generating device 5 is arranged on the peripheral side of the melting area of the printing material of the 3D printing system. The size and direction of the magnetic field generated by the magnetic field generating device 5 can be adjusted.

[0032] Preferably, the magnetic field generating device 5 may include an electromagnet and a current controller; the current controller controls the magnitude and direction of the current flowing through the electromagnet to control the magnitude and direction of the generated magnetic field.

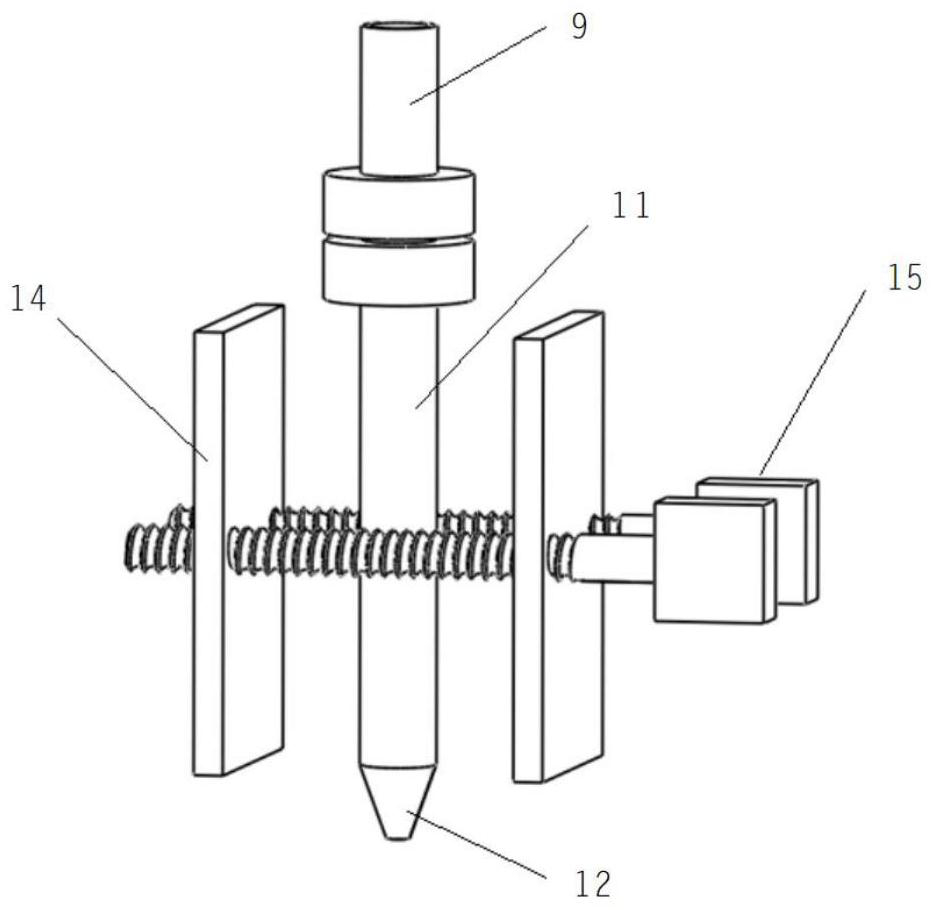

[0033] Preferably, a mounting frame 15 for installin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com