Bottom baffling type two-way oxygen supply pyrolysis gasification furnace for plateau

A pyrolysis gasification and baffle technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as odor air pollution, soil pollution, and affecting the quality of pyrolysis gasification, achieving secondary Complete combustion, improve the quality of pyrolysis and gasification, and improve the effect of distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

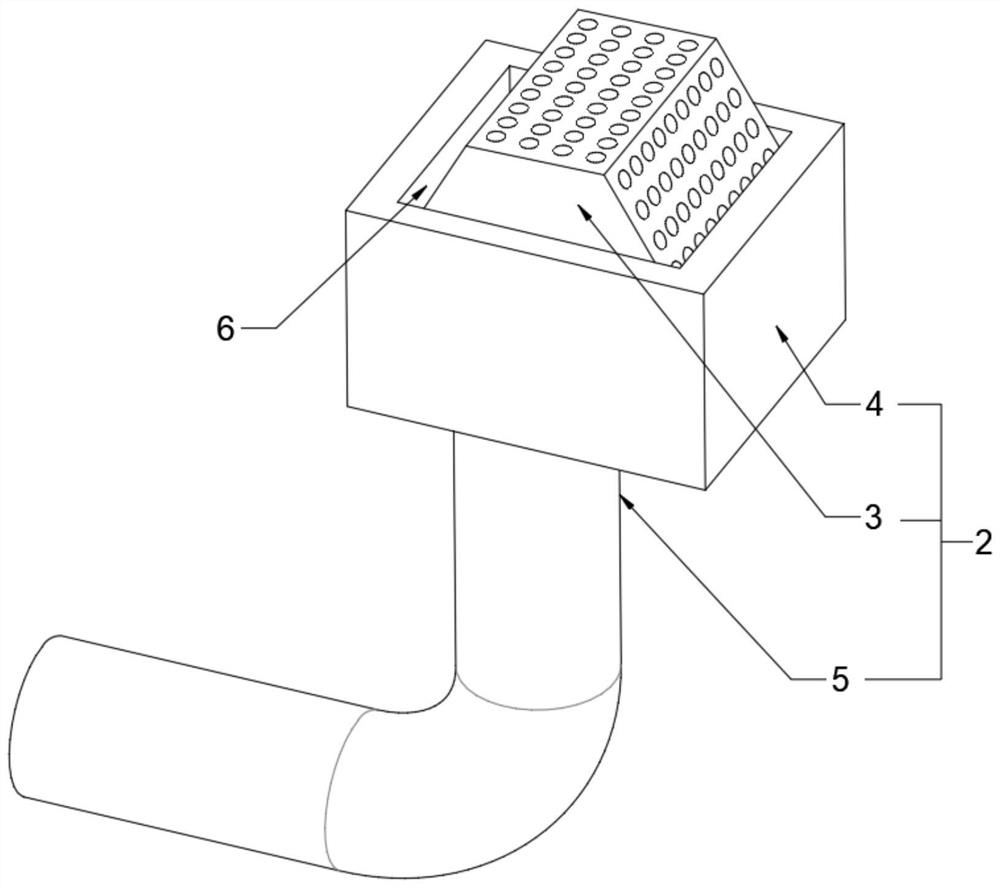

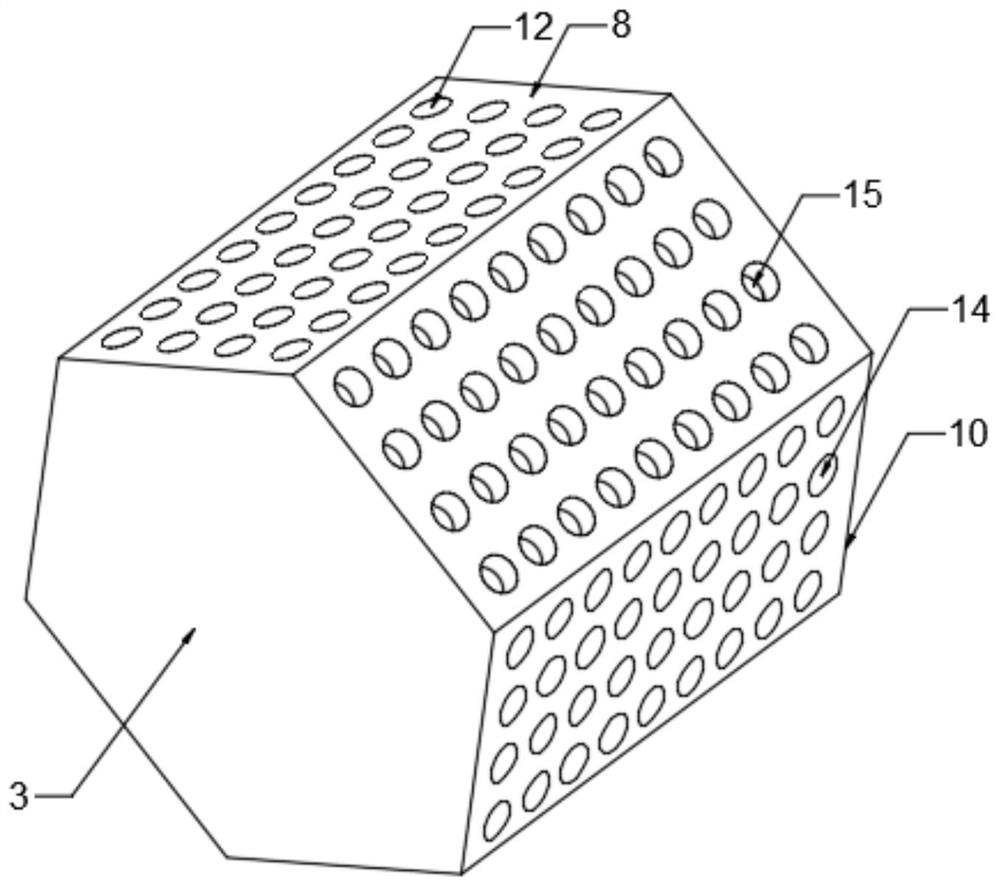

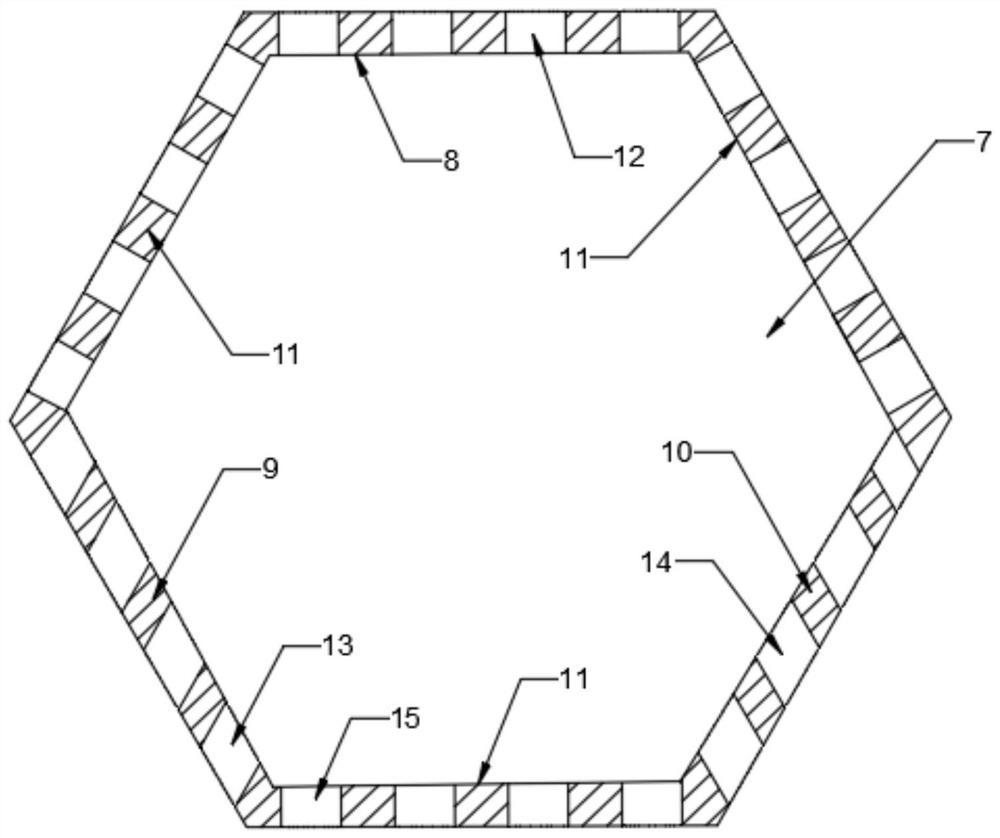

[0027] Embodiment one, as Figure 1 to Figure 3As shown, a bottom baffle type bidirectional oxygen supply pyrolysis gasifier for the plateau includes a gasification furnace body 1 and an oxygen supply assembly 2, and the oxygen supply assembly 2 is arranged in the gasification furnace body 1, The oxygen supply assembly 2 includes a rotating oxygen supply block 3, an oxygen supply housing 4 and an oxygen supply pipeline 5. The oxygen supply housing 4 is provided with a rotating chamber 6 with an open top, and the rotating oxygen supply block 3 is rotatably arranged in the rotating chamber 6. The oxygen supply pipeline 5 is fixedly installed on the gasifier body 1, one end of the oxygen supply pipeline 5 is connected to the bottom of the oxygen supply shell 4, and the oxygen supply pipeline 5 communicates with the rotating chamber 6; the shape of the rotating oxygen supply block 3 is six The two ends of the prism and the rotating oxygen supply block 3 are rotatably connected wit...

Embodiment 2

[0029] Embodiment two, such as Figure 4 and Figure 5 As shown, the furnace body 1 of the gasifier is provided with a furnace bridge 24. The furnace bridge 24 is located below the oxygen supply shell 4. The furnace bridge 24 includes a furnace bridge frame 25 and two sets of furnace bridge mechanisms 26. On the inner wall of the furnace body 1, two groups of furnace bridge mechanisms 26 are arranged on the furnace bridge frame 25 at intervals, and an oxygen supply gap 27 for the oxygen supply pipeline 5 to pass is formed between the two groups of furnace bridge mechanisms 26, and the oxygen supply gap 27 The width of the furnace bridge mechanism 26 includes a plurality of first rotating shafts 28 and a plurality of second rotating shafts 29, and the first rotating shafts 28 and the second rotating shafts 29 are alternately arranged. The first rotating shaft 28 and the second rotating shaft 29 are rotatably connected to the furnace bridge 25 through bearings. The rotating dir...

Embodiment 3

[0031] Embodiment three, as Figure 7 As shown, the top of the gasifier body 1 is connected with a gas outlet pipe 37, the gas outlet pipe 37 is connected with a temporary storage box 38, the temporary storage box 38 is connected with an exhaust pipe 39, and the gas outlet pipe 37 is provided with a gas path check valve. 40. The exhaust pipe 39 is provided with a switch valve 41; the gas generated by the burning of garbage enters the temporary storage box 38 through the air outlet pipe 37. Since the gas circuit check valve 40 can only be conducted in one direction, the gas can only pass through the outlet pipe. The gas pipe 37 enters the temporary storage box 38 and cannot flow into the gasification furnace body 1 from the temporary storage box 38. The gas is temporarily stored through the temporary storage box 38, and the switch valve 41 is opened to make the gas in the temporary storage box 38 flow from Exhaust pipe 39 is discharged for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com