Well washing sampling pump for environmental monitoring well

An environmental monitoring and sampling pump technology, applied in the direction of sampling devices, etc., can solve the problems of slowing down the rotation speed of the impeller, retention, and slowing the pumping speed, and achieves the effect of accelerating the rotation speed, maintaining the rotation speed, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

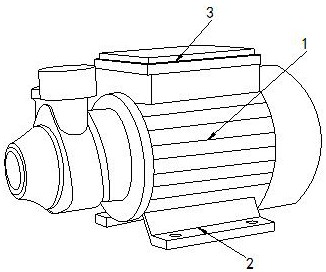

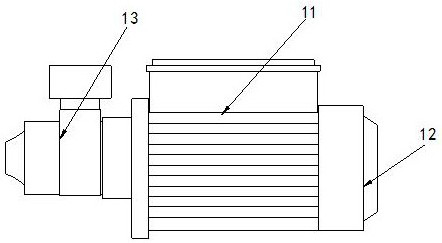

[0029] Its structure includes a main body 1, a base 2, and a top cover 3. The bottom of the main body 1 is provided with a base 2, and the top cover 3 is engaged with the top of the main body 1. The main body 1 includes a heat dissipation shell 11 and a rear engaging cover. 12. The pumping device 13, the bottom end of the heat dissipation shell 11 is connected with the base 2, and the top cover is engaged with the top cover 3, the rear engaging cover 12 is flange-connected to the rear end of the heat dissipation shell 11, the pumping device 13 is connected to the front end of the heat dissipation shell 11.

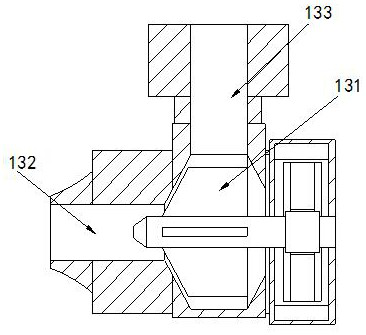

[0030] The pumping device 13 includes a rotating impeller 131, a water inlet 132, and a water pumping tank 133. The rotating impeller 131 is connected to the inside of the heat dissipation shell 11. The water inlet 132 is arranged at the front end of ...

Embodiment 2

[0035] Example 2: Please refer to Figure 7-Figure 9 , the specific embodiments of the present invention are as follows:

[0036]The sealing device a3 includes a sealing plate c1, a sand retaining bar c2, an embedded groove c3, a collar c4, a ball c5, and a sealing ring c6, the sealing plate c1 is arranged at the rear end of the rotating shaft a1, and the sand retaining bar c2 is set There are eight of them, and they are arranged around the end face of the sealing plate c1. The embedding groove c3 is set in the middle of the inner sealing plate c1, the collar c4 is engaged in the embedding groove c3, and the ball c5 is provided with More than eight, arranged around the side end surface of the collar c4, and movably matched with the side end of the embedded groove c3, the sealing ring c6 is nested on the side end surface of the sealing plate c1, the collar c4 is connected with the rotating shaft a1 The transitional fit facilitates the contact between the collar c4 and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com