Cutting tool

A technology of cutting tools and unit layers, which is applied in the direction of manufacturing tools, workpieces, drilling accessories, etc., and can solve problems such as cutting edge wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0185] Hereinafter, although an Example is given and this invention is demonstrated in detail, this invention is not limited to these Examples.

[0186] "Making of Cutting Tools"

[0187]

[0188] First, as a substrate to be coated, substrates made of cemented carbide shown in Table 1 below (hereinafter, may be simply referred to as “substrates”) were prepared (first step). Specifically, first, raw material powders having a mixing composition (mass %) described in Table 1 were uniformly mixed. "Remainder" in Table 1 indicates that WC occupies the remainder of the mixed composition (mass %).

[0189] [Table 1]

[0190]

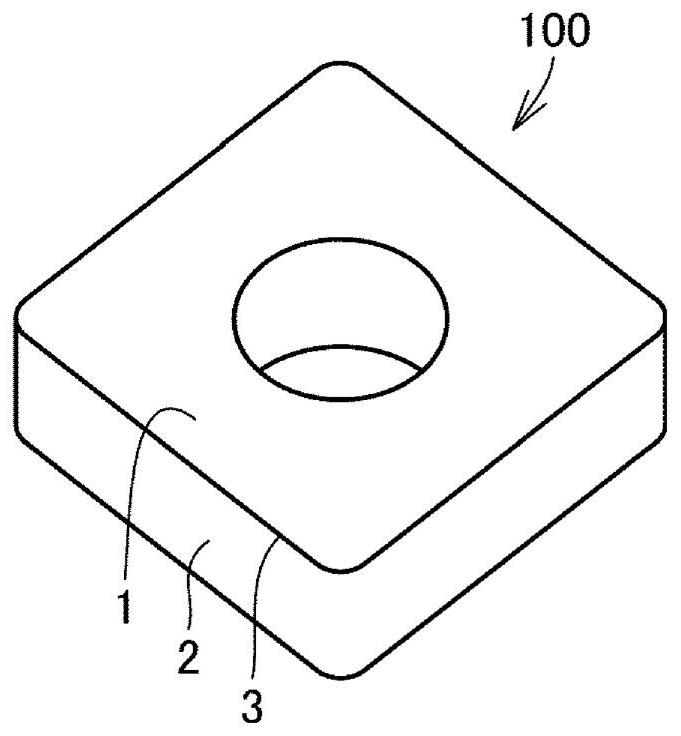

[0191] Next, the mixed powder was press-molded into a predetermined shape, and then sintered at 1300-1500° C. for 1-2 hours to obtain the above-mentioned substrate (substrate shape (JIS standard): SEET13T3AGSN-G). It should be noted that SEET13T3AGSN-G is the shape of an indexable cutting insert for milling.

[0192]

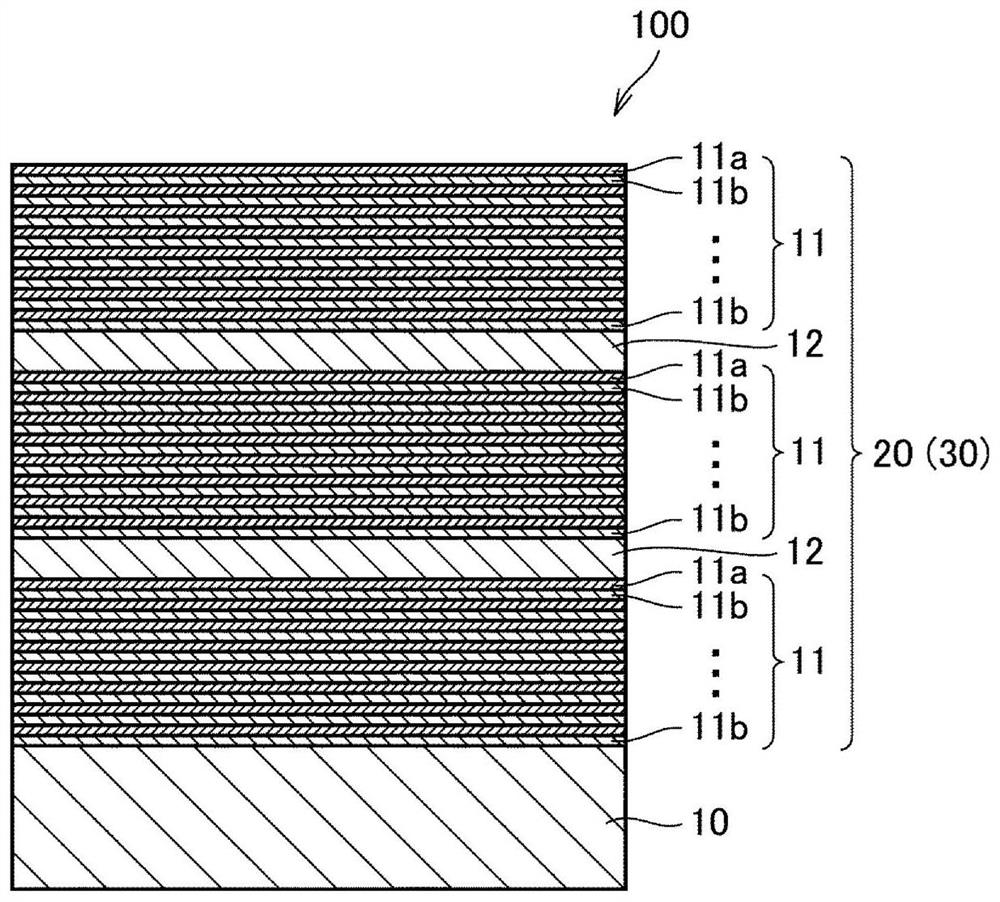

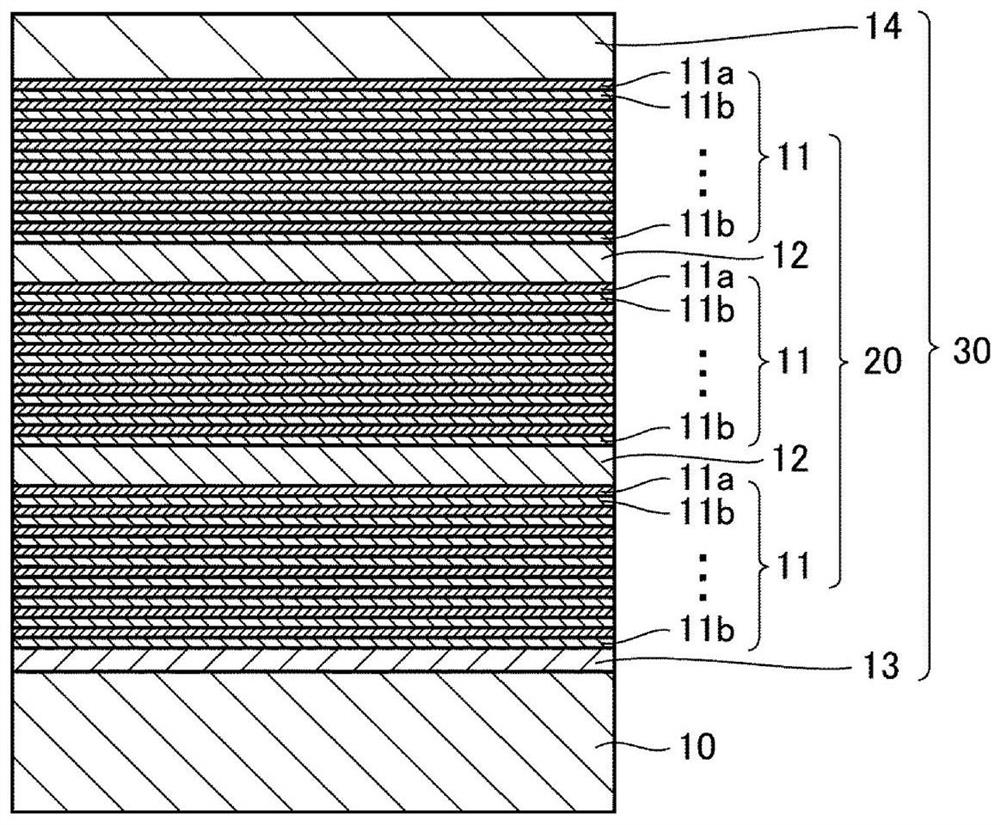

[0193] By forming the base laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap