Composite component for a motor vehicle locking system

A technology of composite material components and motor vehicles, applied in the field of mass inertial rods, can solve problems such as the opening of the joystick locking mechanism and the unintentional opening of the side door, and achieve the effects of high structural freedom, low cost, and low manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

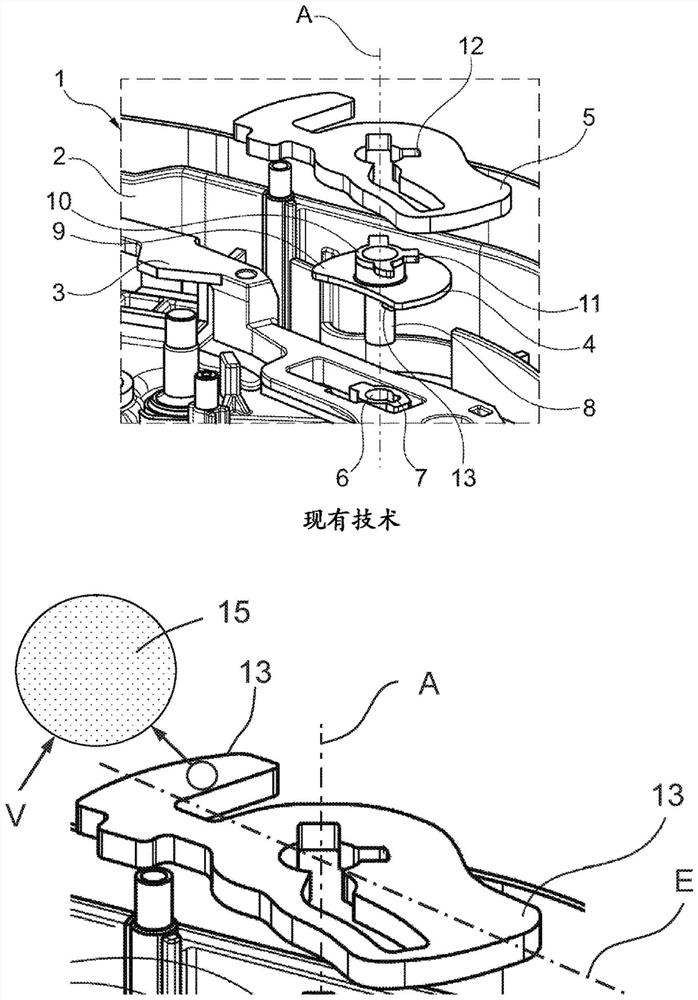

[0027] exist figure 1 A motor vehicle lock 1 is shown in a three-dimensional view according to the prior art and according to DE 10 2018 116 313, wherein only a part of the components of the motor vehicle lock 1 is shown. exist figure 1 The housing 2, the moving element 3, the plastic mandrel 4 and the mass-inertia element 5 are shown in . The mass-inertia element 5 is fixed along the axis A on the plastic mandrel 4 , wherein the plastic mandrel 4 can be inserted into the opening 6 of the housing 2 . An extension of this opening 7 can be seen in the opening 7 , so that the plastic mandrel 4 can be inserted into the opening 6 in a form-fitting manner.

[0028] The plastic mandrel 4 has a cylindrical extension 8 extending through the housing 2 . The joint surface 9 serves on the one hand as a seat, for example, for riveting the cylindrical extension 8 and, on the other hand, as a guide surface for the displacement element 3 . Furthermore, the task of the joint surface 9 is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com