Full-automatic side feeding computer saw with manipulator and control system and control method of full-automatic side feeding computer saw

A manipulator and fully automatic technology, which is applied in the field of computer saws, can solve the problems of manpower consumption, increased labor costs, and low time efficiency, and achieve the effects of convenient production operations, reduced manpower consumption, and lower labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

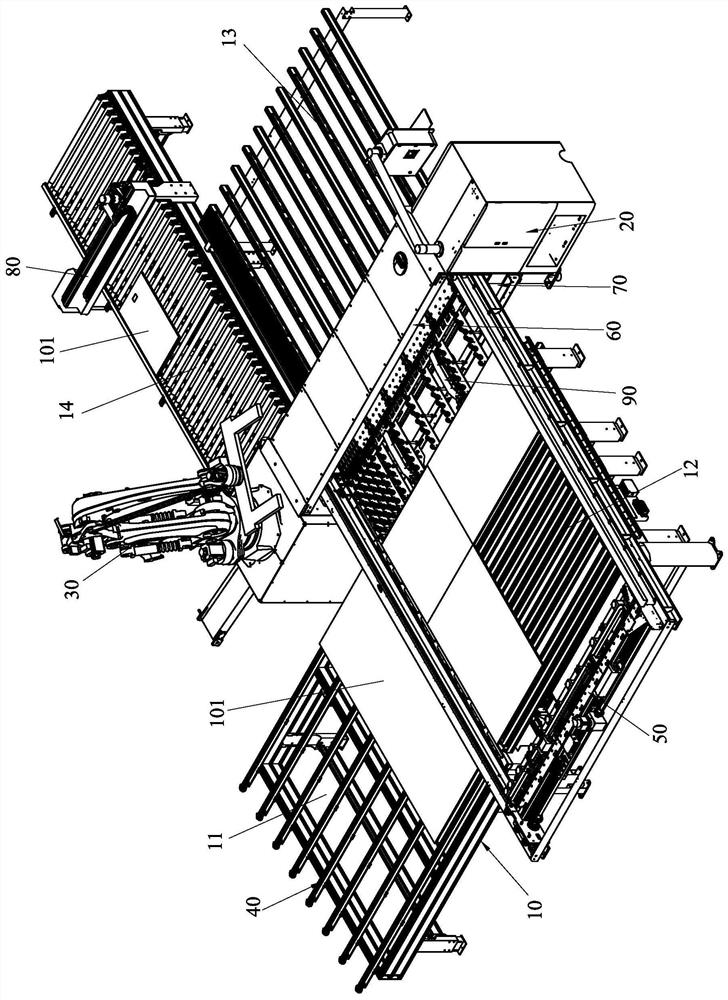

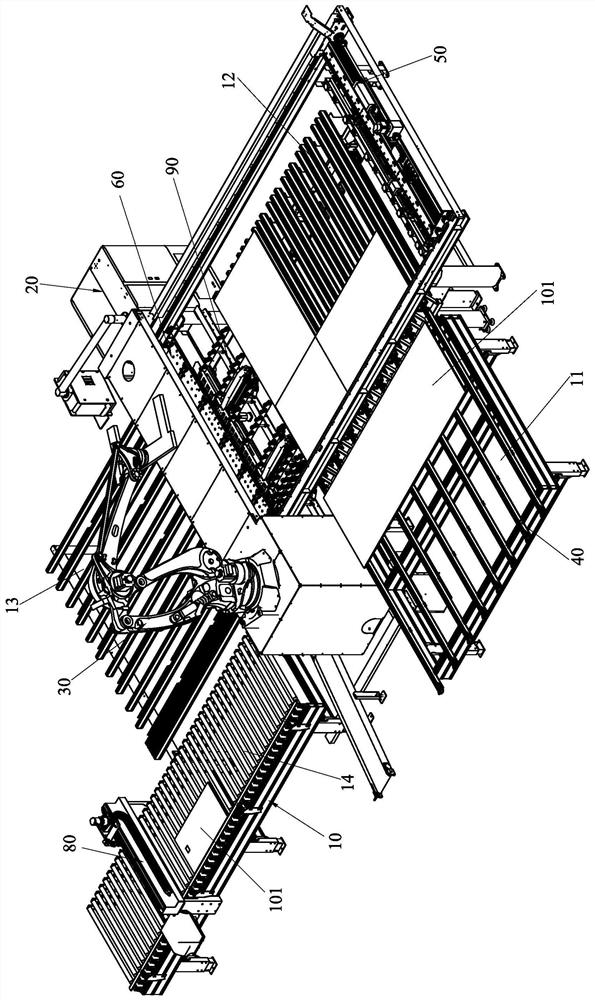

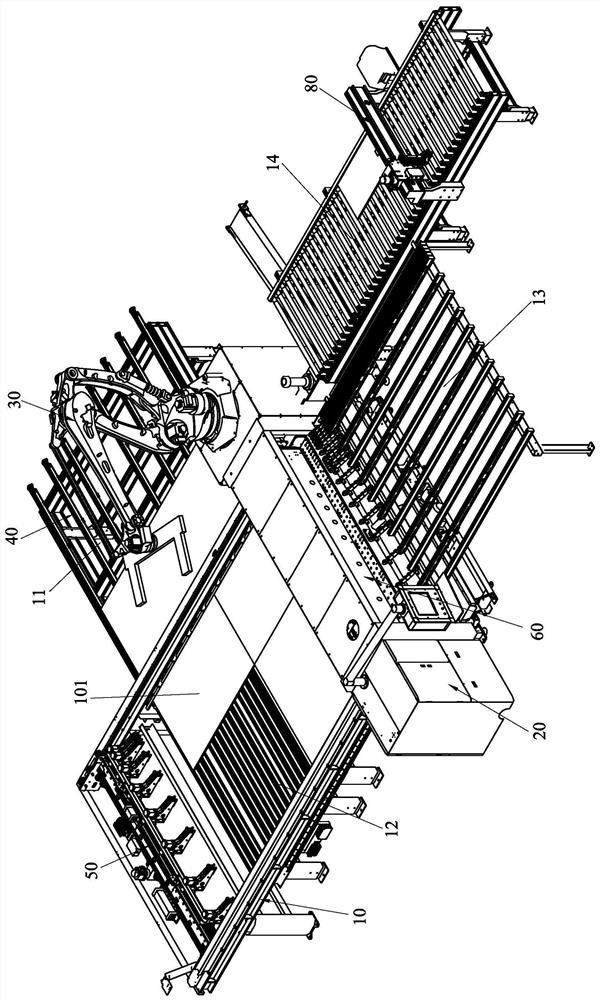

[0088] Please refer to Figure 1 to Figure 8As shown, it has shown a specific structure of a fully automatic side feeding computer saw with a manipulator in a preferred embodiment of the present invention, including a frame 10, a control cabinet 20, a manipulator retrieving device 30, and a feeding device 40 , The clamp feeding device 50 , the pressing device 60 , the cutting device 70 and the labeling device 80 .

[0089] The frame 10 has an incoming material area 11, a processing area 12, a material output area 13 and a labeling area 14; the control cabinet 20 is arranged on the frame 10; the manipulator retrieving device 30 is arranged on the frame 10 and connected The control cabinet 20, the aforementioned incoming material area 11, the processing area 12, the discharging area 13 and the labeling area 14 are arranged around the manipulator retrieving device 30; Side, the discharge area 13 is located at the front side of the processing area 12, the labeling area 14 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com