Novel double-circulation type magnetic grinding machine

A magnetic grinding and double-cycle technology, which is applied to machine tools suitable for grinding the edge of workpieces, grinding machines, surface polishing machine tools, etc., can solve the problems of reducing the processing capacity of magnetic grinding machines and prolonging the processing time of alloy parts, so as to facilitate processing , Improve processing capacity, reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 3-8 The application is described in further detail.

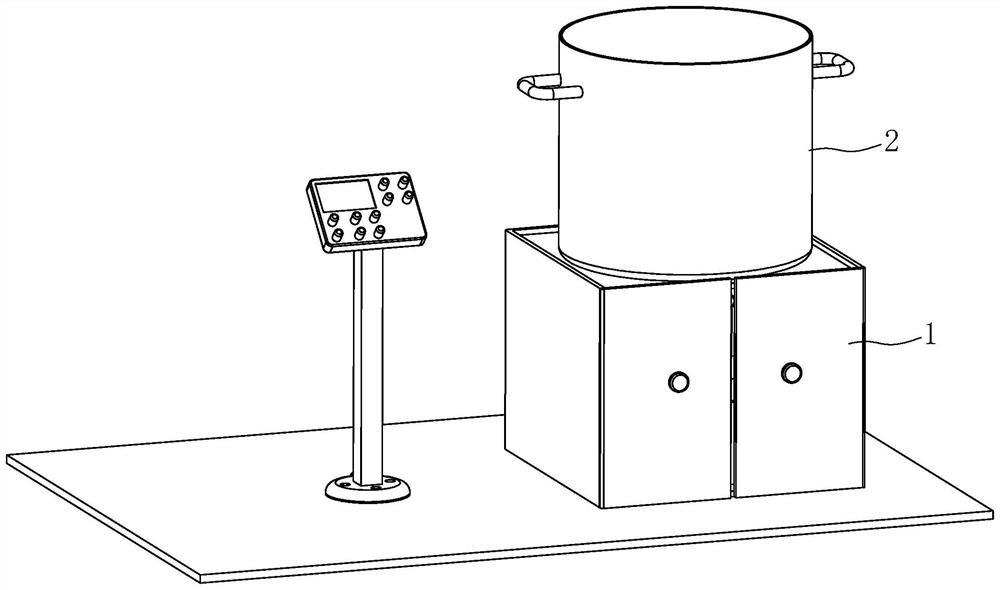

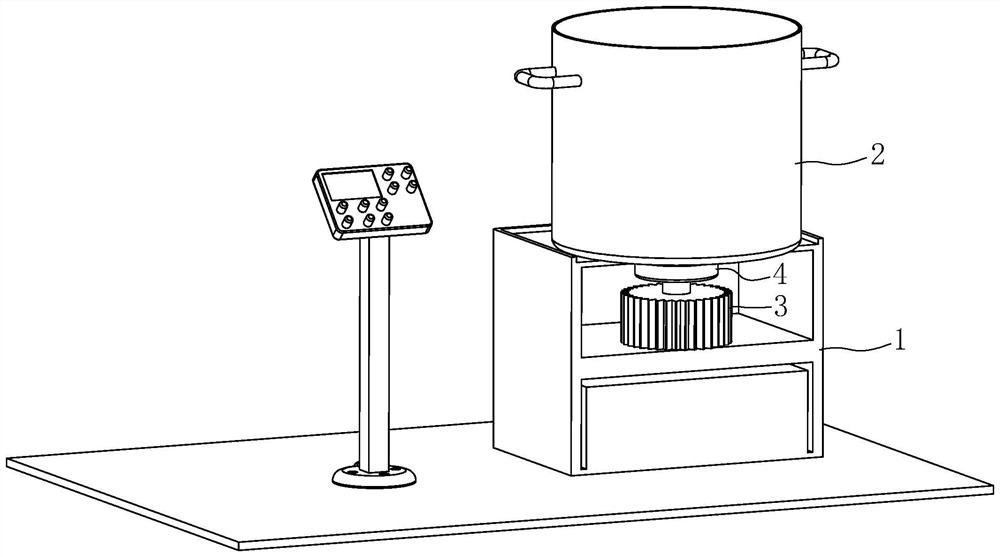

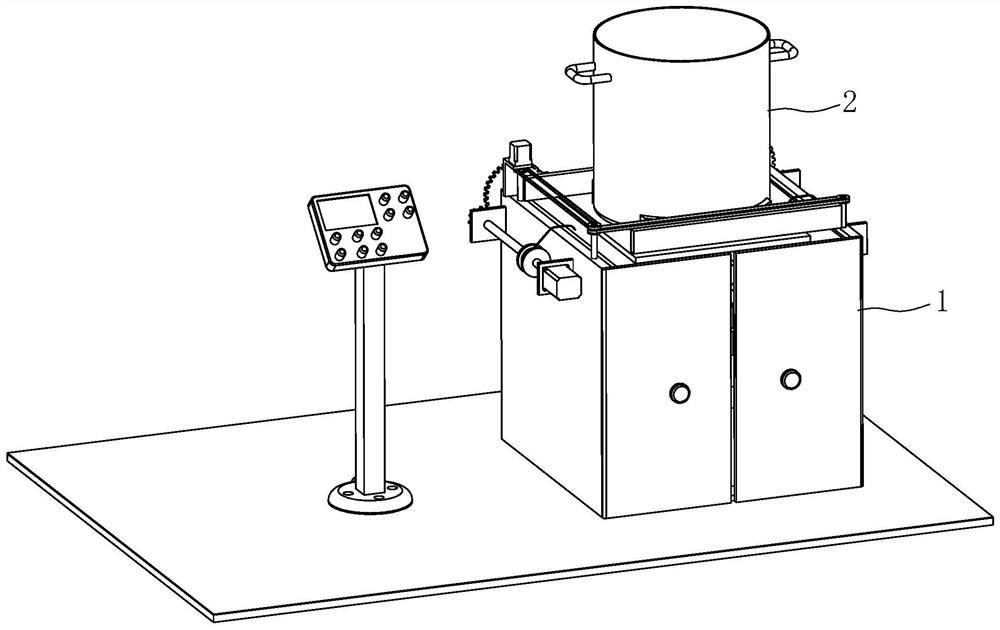

[0040] The embodiment of the present application discloses a new double-cycle magnetic grinder. refer to image 3 , the double-cycle new magnetic grinding machine includes a body 1, and a first magnet 4 is installed in the body 1 for rotation. In the embodiment of the application, the plane where the first magnet 4 is located is parallel to the top surface of the body 1, and a useful For the first motor 3 that drives the first magnet 4 to rotate, the length direction of the output shaft of the first motor 3 is perpendicular to the top surface of the body 1, and the first magnet 4 is fixedly arranged on the output shaft of the first motor 3; During surface treatment, the aluminum alloy parts are placed in the processing cylinder 2, and detergent and stainless steel needles are added to the processing cylinder 2; then the first motor 3 is started, and the first motor 3 drives the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com