Process for the manufacture of polyethylene or polyethylene-vinyl acetate copolymer

A technology of vinyl acetate and its manufacturing method, which is applied in the field of manufacturing polyethylene or polyethylene-vinyl acetate copolymer, can solve the problems of yellowing of molded objects, reduction of organic peroxide concentration, reduction of polymerization productivity, etc., and achieve Improvement of processing productivity and effect of suppression of increase in fish eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

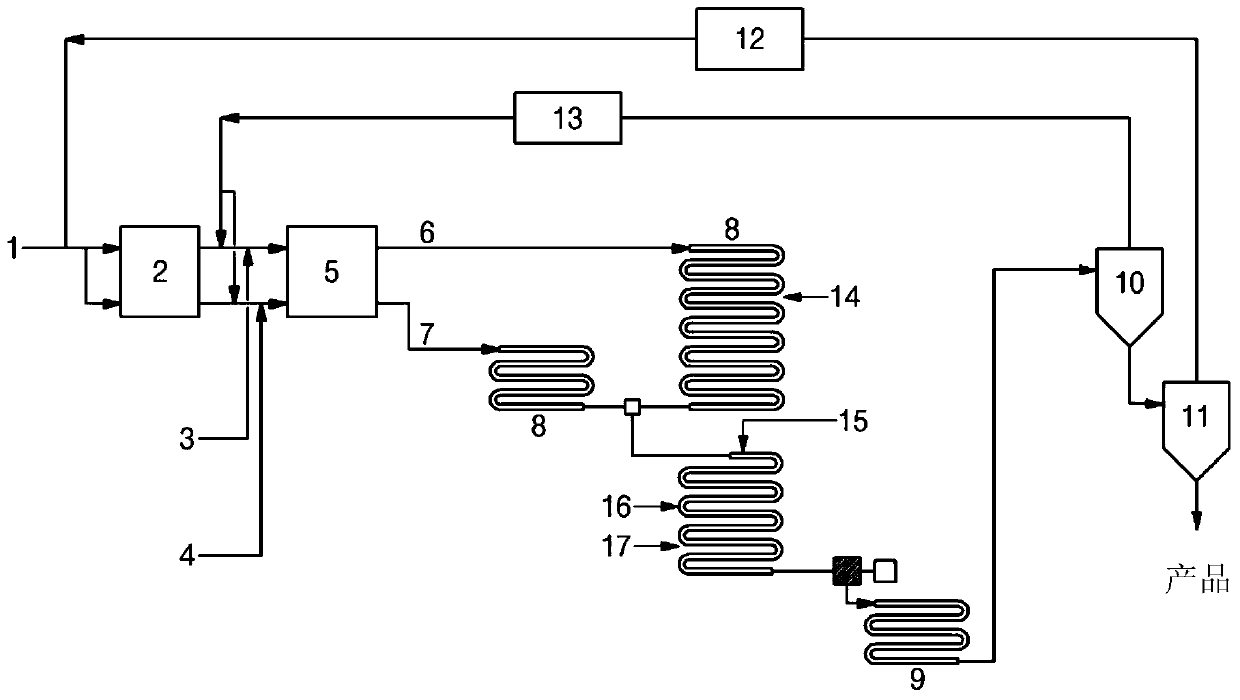

[0040] Such as figure 1 As shown, polyethylene resin was produced in a tubular reactor with 4 reactors.

[0041] The ethylene monomer and vinyl acetate monomer compressed by the compressor are preheated to the initial temperature of the reactor, and then injected into the tubular reactor containing 4 reaction zones.

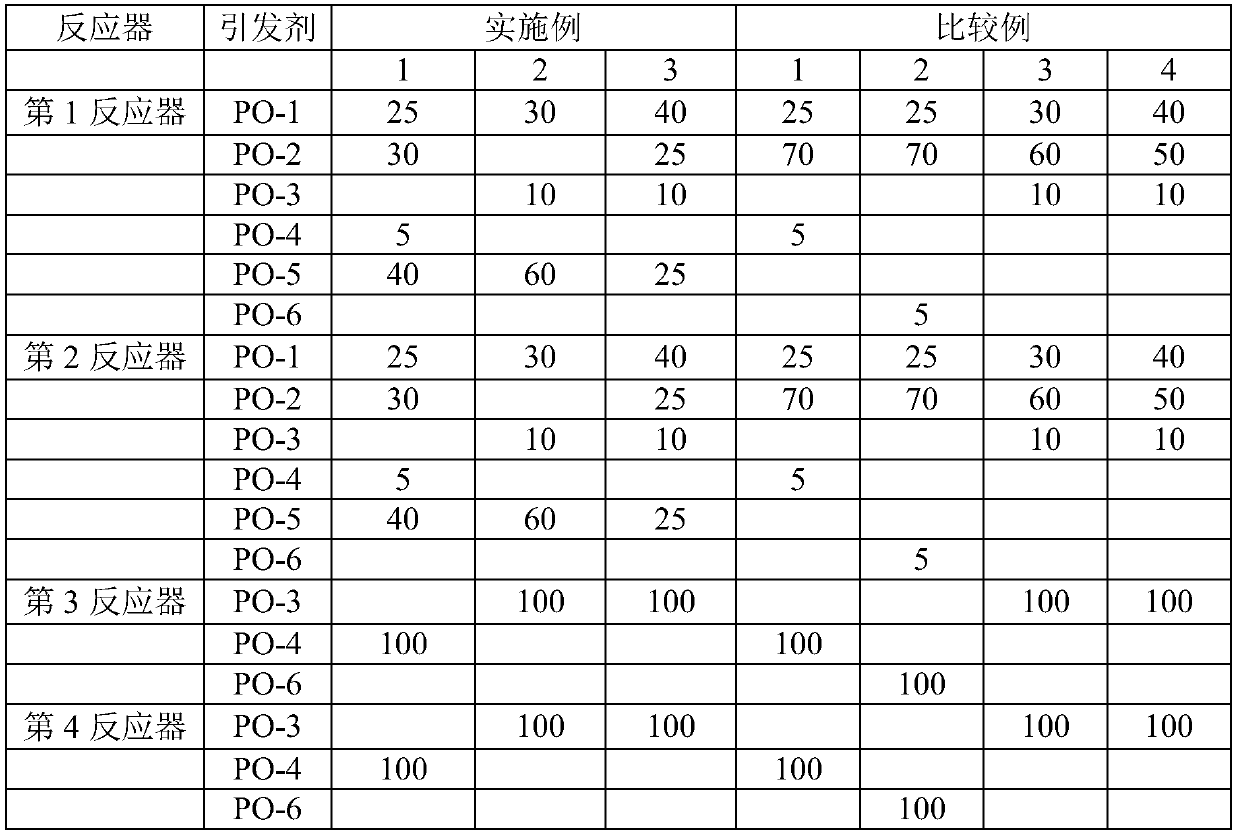

[0042] The monomer is divided into the main airflow entering the first reactor and the auxiliary airflow directly entering the second reactor, and the input is at a ratio of 55:45. Use propionaldehyde or propylene as the molecular weight regulator, and inject the main airflow and auxiliary airflow at a ratio of 50:50. The injection amount of the molecular weight regulator is shown in Table 2. The type of organic peroxide used as a reaction initiator and the composition ratio of each component are shown in Table 1 below, and the polymerization conditions such as pressure, temperature, and input amount of a molecular weight modifier in each stage of the reaction ...

Embodiment 2

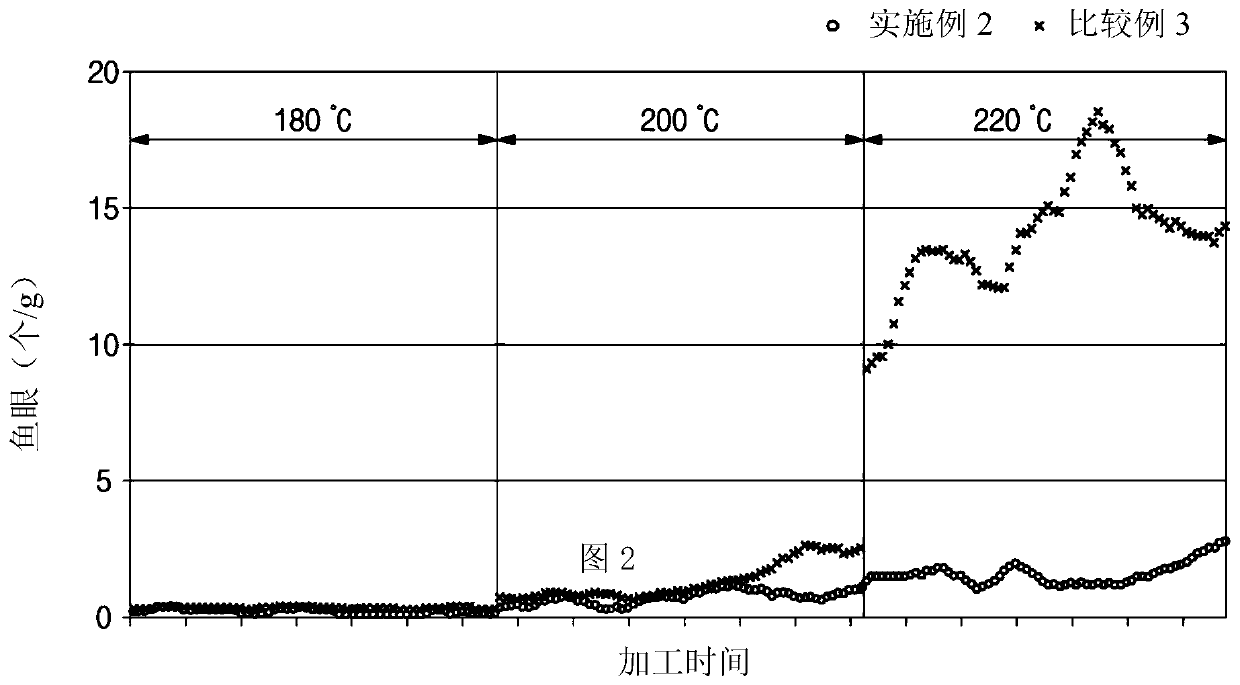

[0052] Production was carried out in the same manner as in Example 1 above, and ethylene and vinyl acetate monomers were mixed and charged in the ratio shown in Table 2 as monomers to produce an ethylene-vinyl acetate copolymer. In the first reactor and the second reactor where the reaction temperature is lower than 230°C, tert-amyl peroxide 2-ethylhexanoate with a half-life temperature of 1 second at 185°C is mixed with tert-butyl-based organic peroxide. The oxides were mixed together at the ratio shown in Table 1 and used. At the stage of granulating the product, SONGNOX-1076 (octadecyl 3-(3,5-di-tert-butyl-4-hydrophenyl) propionate) as an antioxidant was prepared by mixing 400 ppm.

Embodiment 3

[0054] Production was carried out in the same manner as in Example 1 above, and ethylene and vinyl acetate monomers were mixed and charged in the ratio shown in Table 2 as monomers to produce an ethylene-vinyl acetate copolymer. In the first reactor and the second reactor where the reaction temperature is lower than 230°C, tert-amyl peroxide 2-ethylhexanoate with a half-life temperature of 1 second at 185°C is mixed with tert-butyl-based organic peroxide. The oxides were mixed together at the ratio shown in Table 1 and used. At the stage of granulating the product, SONGNOX-1076 (octadecyl 3-(3,5-di-tert-butyl-4-hydrophenyl)propionate) as an antioxidant was prepared at 1200ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com