Dough leaf processing machine

A processing machine and noodle leaf technology, which is applied in the direction of dough extruder, dough sheeter/rolling machine/rolling stick, dough processing, etc., can solve the problem of low efficiency of manual rolling, inability to work for a long time, work High strength and other problems, to achieve the effect of improving processing effect, continuous strength, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments.

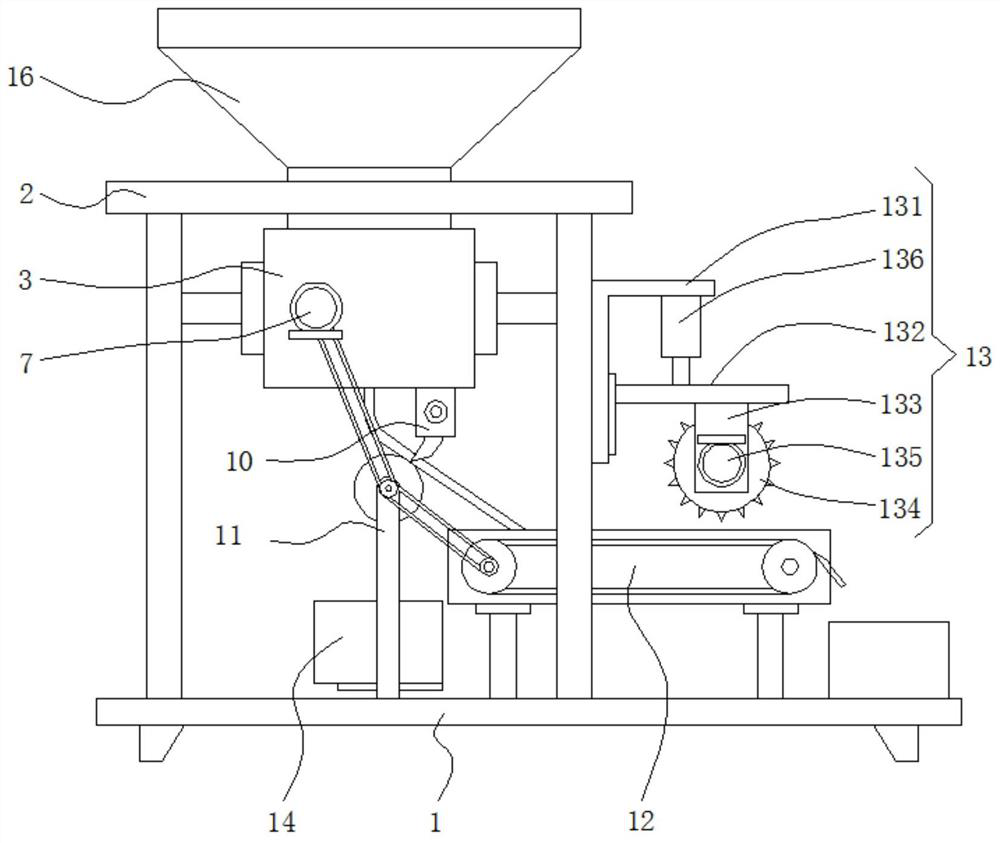

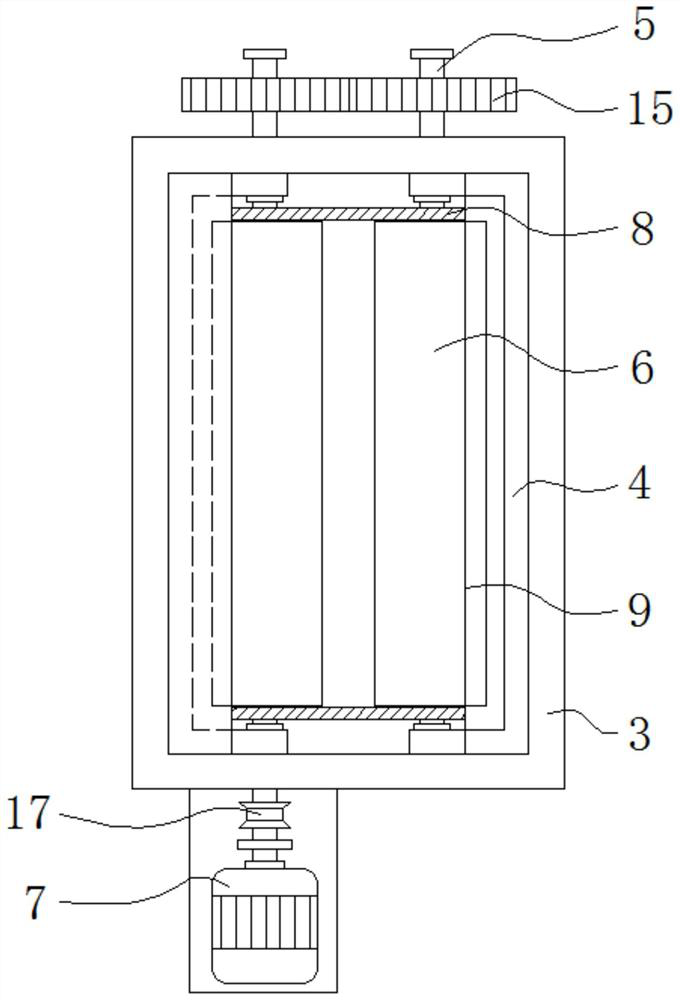

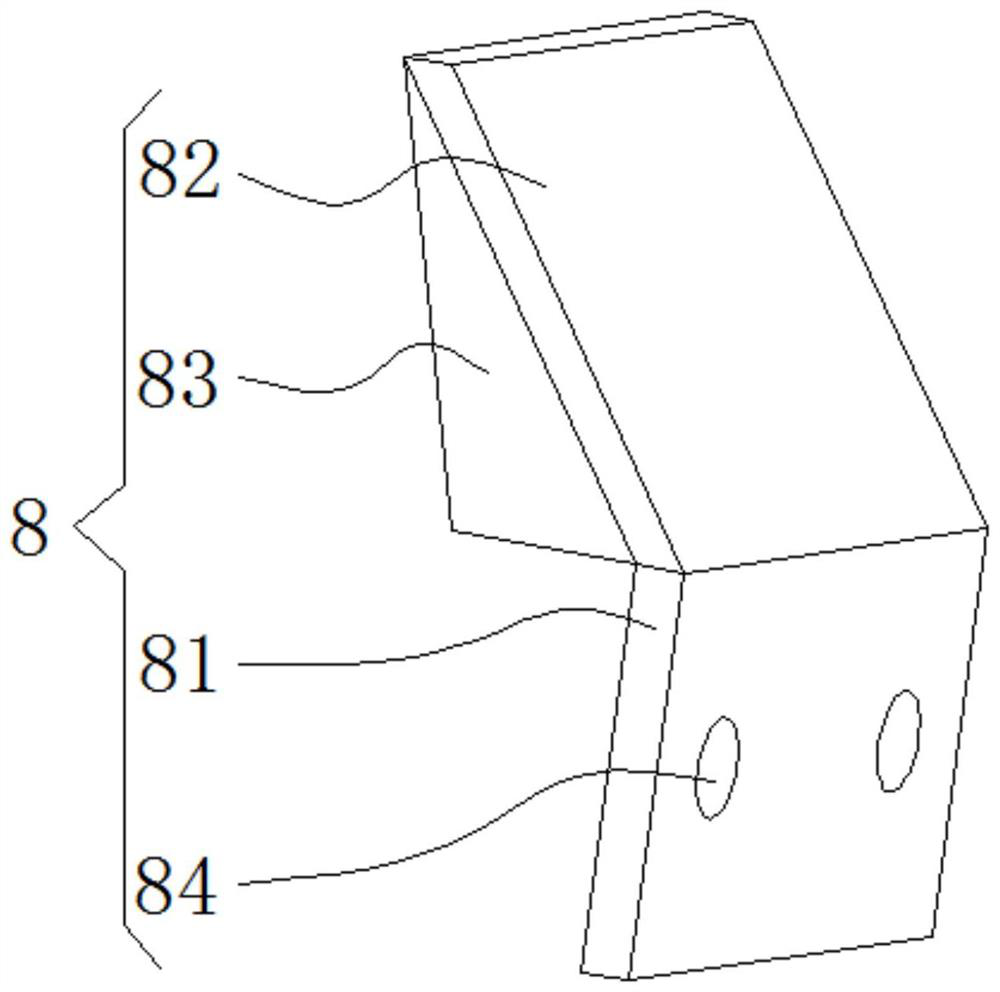

[0036] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A schematic structural diagram of a preferred embodiment of the dough leaf processing machine provided by the present invention; figure 2 for figure 1 The top view of the structure of the movable frame shown; image 3 for figure 2 The three-dimensional schematic diagram of the shielding assembly shown; Figure 4 for figure 1 structural side view of the conversion assembly shown; Figure 5 for figure 1 Structural side view of the cropped assembly shown. The face leaf processing machine includes:

[0037] base 1;

[0038] U-shaped bracket 2, the U-shaped bracket 2 is fixed on one side of the top of the base 1;

[0039] The movable frame 3, the two sides of the movable frame 3 are fixed on both sides of the inner wall of the U-shaped bracket 2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com