Automatic screwdriver with adjustable operation station

A pneumatic screwdriver, adjustable technology, used in screwdrivers, power tools, manufacturing tools and other directions, can solve problems such as difficulty in manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

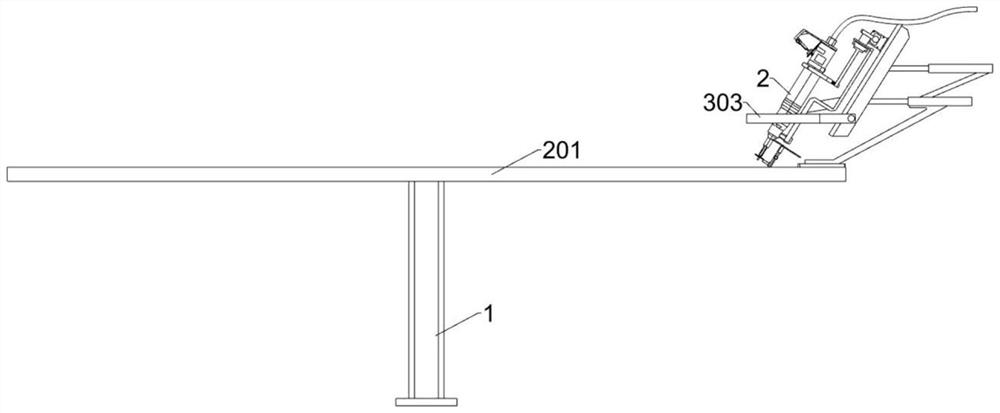

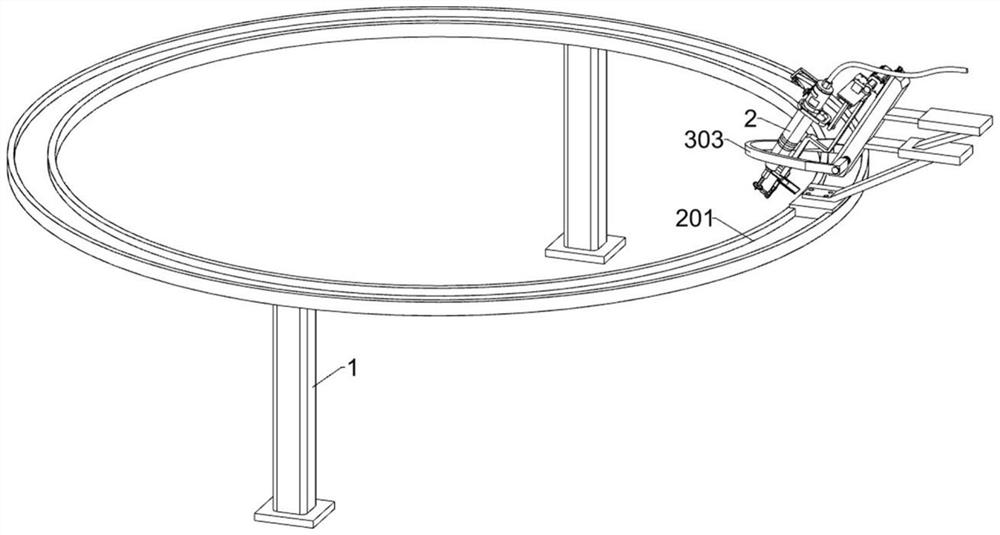

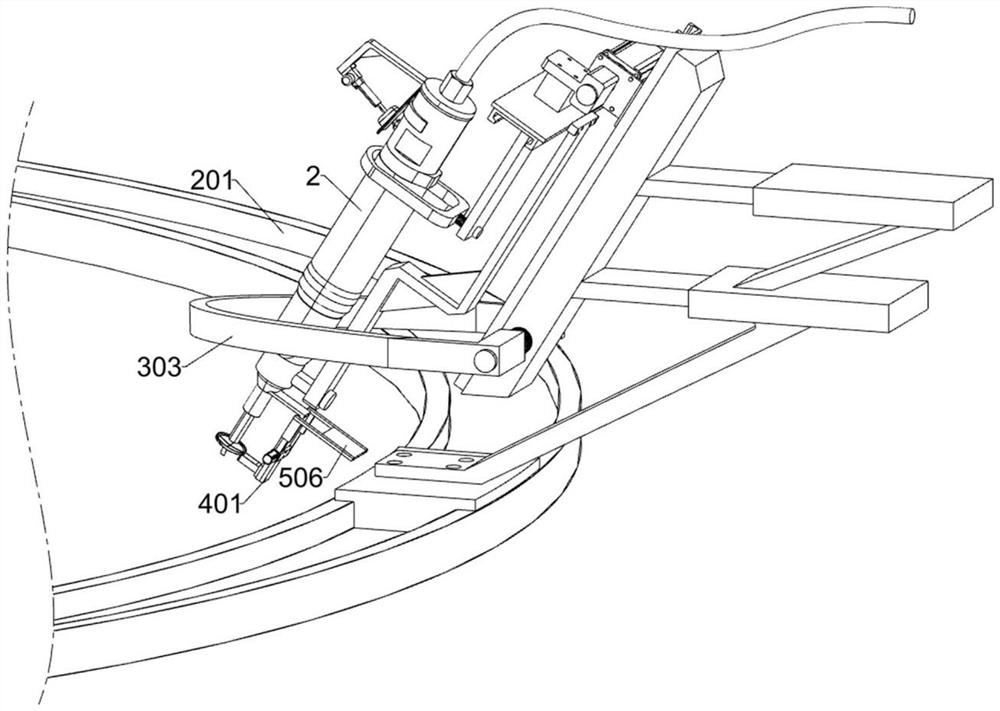

[0031] An operational station adjustable automatic screwdriver, such as Figure 1-8 As shown, including a fixed base 1, a pneumatic screwdriver 2, an angle adjustment assembly, an obstacle avoidance assembly; the fixed base 1 is provided with two, and the upper surface of the two fixed base 1 is mounted an angle adjustment assembly; angle adjustment component right side There is a pneumatic screwdriver 2; an obstacle avoidance assembly is installed on the right side of the angle adjustment assembly, and the barrier avoidance assembly is located outside the pneumatic screwdriver 2.

[0032] The angle adjustment assembly includes a first slip rail 201, a first driving member 202, a first connecting plate 203, a first elastic member 204, a second connecting plate 205, a second elastic member 206, mounting plate 207, a second sliding rail 208 , The second drive member 209, the first electric rotary shaft 2010, the first T-plate 2011, the second T-plate 2012, the third slide rail 2013, ...

Embodiment 2

[0042] On the basis of Example 1, if figure 1 , Figure 9-10 The cleaning assembly is further included, and the lower side of the pneumatic screwdriver 2 is mounted, and the cleaning assembly includes a third L-shaped plate 401, a fourth slide rail 402, a fifth drive member 403, a collection frame 404, a ring block 405, The cleaning device 406 and the limit panel 407; the lower side of the pneumatic screwdriver 2 is fixed to the third L-shaped plate 401; the third L-shaped plate 401 is welded with the fourth slide rail 402; the fourth slide rail 402 slides A fifth drive member 403 is connected; the left side surface of the fifth drive member 403 is welded to collect box 404; the left side of the collecting frame 404 has a ring block 405; the inner side of the annular block 405 is provided with an annular array of cleanup 406; The lower side of the block 405 is welded to two front and rear symmetrical limit panels 407.

[0043] The ring block 405 has an gap corresponding to the posi...

Embodiment 3

[0047] On the basis of Example 2, if figure 1 , Figure 11-12 As shown, a silicid wire processing assembly is also included, and a silicone processing assembly is mounted on the right side of the third L-shaped plate 401, and the wire processing assembly includes a fourth L-shaped plate 501, a second electric rotary shaft 502, a transmission shaft 503, and the first Three elastic parts 504, fourth connecting plate 505 and auxiliary device 506; the third L-shaped plate 401 is connected to the fourth L-shaped plate 501; the middle of the third L-plate 401 is rotated connected to the drive shaft 503; fourth The second electric rotary shaft 502 is mounted on the front side of the L-shaped plate 501; the second electric rotary shaft 502 outputs two third elastic members 504, the exterior surface of the drive shaft 503; two third elastic parts 504 The upper end faces are fixed with a fourth connecting plate 505; the two fourth connecting plates 505 are mounted with auxiliary device 506. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com