Construction pipe jacking process of new pipe roofing method

A technology of jacking and new pipes, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of surrounding soil disturbance, easy encounter with obstacles, easy top deviation of construction pipes, etc., to achieve reasonable force and reduce Fatigue damage, the effect of maintaining strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

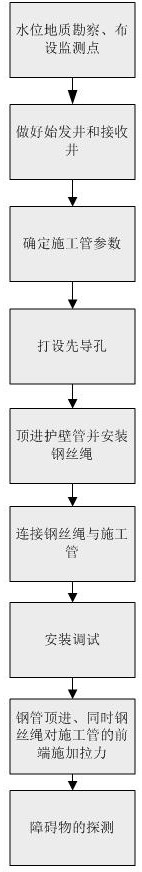

[0027] The invention provides a technical solution: a construction pipe jacking process of a new pipe curtain method, comprising the following steps:

[0028] Step 1: Carry out a detailed survey of the water level geology within the influence range of the pipe curtain, make monitoring points for the ground surface and buildings within the influence range, and establish a complete monitoring system;

[0029] Step 2: Prepare the originating well and the receiving well. The receiving well needs to be equipped with a reaction wall, and the wellhead should be reinforced by grouting;

[0030] Step 3, determining the size, spacing, position and jacking sequence of the construction pipes;

[0031] Step 4: Drill a pilot hole at the center of the design position of the construction pipe;

[0032] Step five, jacking into the retaining pipe and installing the wire rope;

[0033] Step 6, placing a connecting device inside the construction pipe along the axis of the construction pipe to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com