Gob-side entry retaining side goaf collecting device and method

A technology of collecting device and empty lane retention, which is applied in the directions of measuring devices and instruments, can solve the problems of easy damage of the collecting device and difficulty in monitoring, and achieves the effect of being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

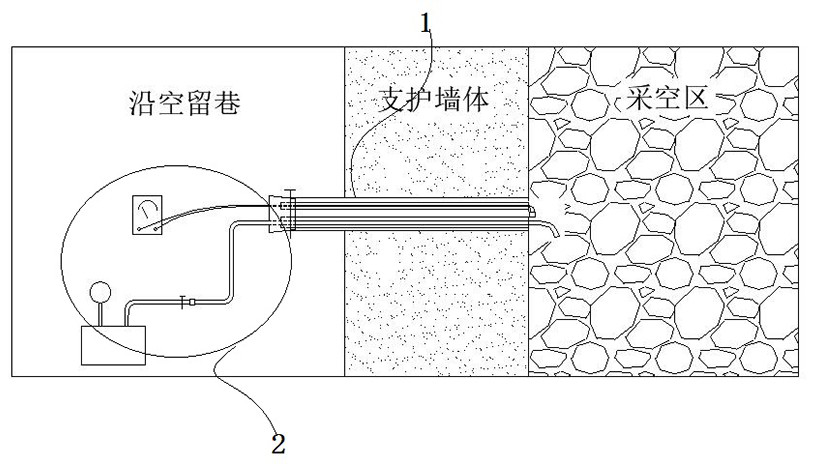

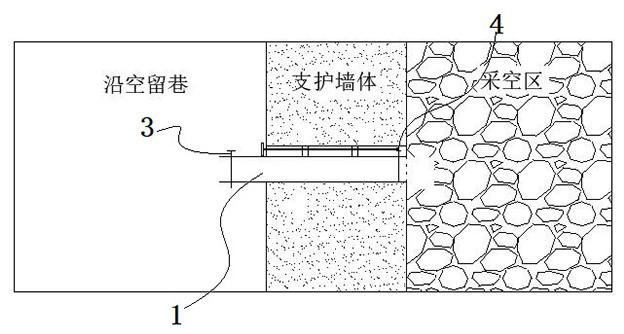

[0041] Such as figure 2 As shown, the valve body includes the first valve body 3 located on the side of the goaf retention, and the sealing and opening of the entire monitoring pipeline 1 is controlled by the first valve body 3; Open the corresponding first valve body 3, and fit the monitoring collection unit 2 into the monitoring pipeline 1; after standing still for 10-20 minutes, perform gas collection and temperature measurement operations; after completing the gas collection and temperature measurement operations, the monitoring collection unit 2 Take it out, and then quickly close the corresponding first valve body 3 .

Embodiment 2

[0043] Such as figure 2 As shown, the valve body includes a first valve body 3 arranged on the side of the gob-side entry, a second valve body 4 arranged on the side of the goaf, and the second valve body 4 passes through the control assembly arranged on the gob-side entry Control opening and closing; when performing temperature collection and gas collection in the goaf, open the corresponding first valve body 3, and extend the monitoring collection unit 2 into the monitoring pipeline 1; at this time, the second valve body is controlled by the control component 4. Open; after standing still for 10-20 minutes, perform gas extraction and temperature measurement operations; after completion of gas extraction and temperature measurement operations, control the second valve body 4 to close through the control component; after the residual gas in the monitoring pipeline 1 is processed, Take out the monitoring collection unit 2, and then close the corresponding first valve body 3; i...

Embodiment 3

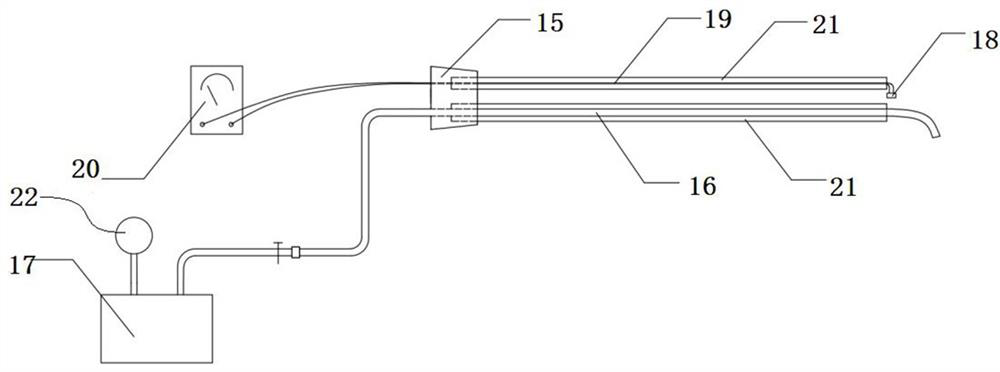

[0049] Such as Figure 3-4 As shown, the monitoring collection unit 2 includes a rubber plug 15 matched with the monitoring pipeline 1, and the rubber plug 15 can expand and shrink in the monitoring pipeline 1 for sealing and fixing; the temperature measuring wire 19 and the bundle tube 16 pass through the rubber plug 15; One end of the tube 16 close to the gob-side entry is connected to the gas automatic negative pressure sampler 17 (model: CFZ-30) through a filter, and the other end of the bundle tube 16 extends to the goaf after the rubber plug 15 is matched with the monitoring pipeline 1 One side; the end of the temperature-measuring wire 19 close to the gob-side entry is connected to an explosion-proof multimeter 20 (model METRALINE EXM 25A), the other end of the temperature-measuring wire 19 is connected to the temperature-measuring probe 18, and the explosion-proof multimeter 20 is connected to the temperature measurement through the temperature-measuring wire 19 The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com