Multifunctional combustion test furnace

A combustion test and test furnace technology, applied in the direction of chemical analysis using combustion, can solve the problems of complex construction, inconvenient transportation, and many restrictions on site conditions, and achieve the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

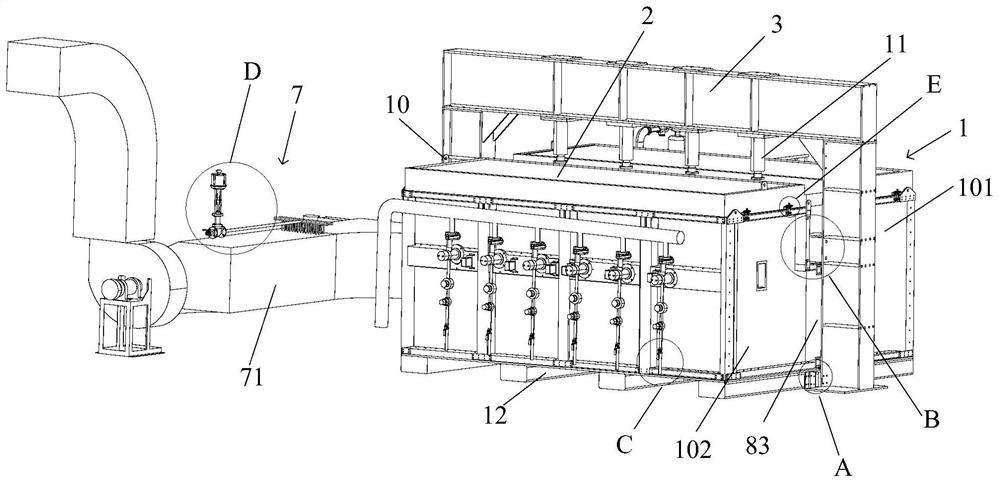

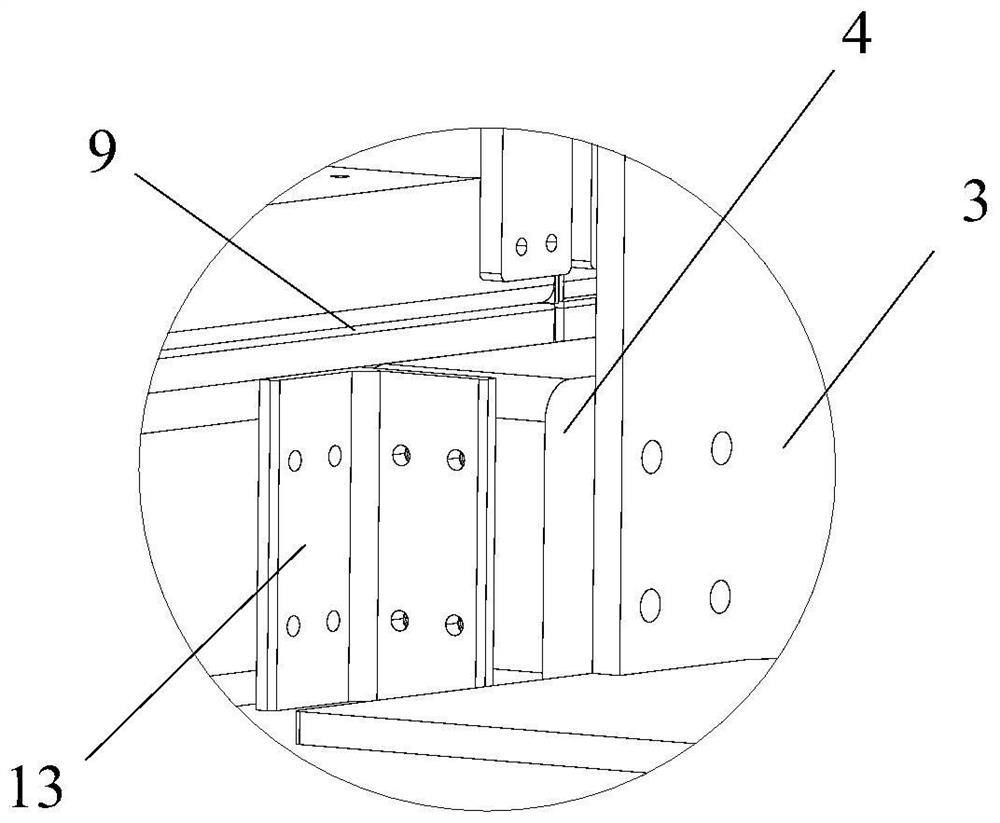

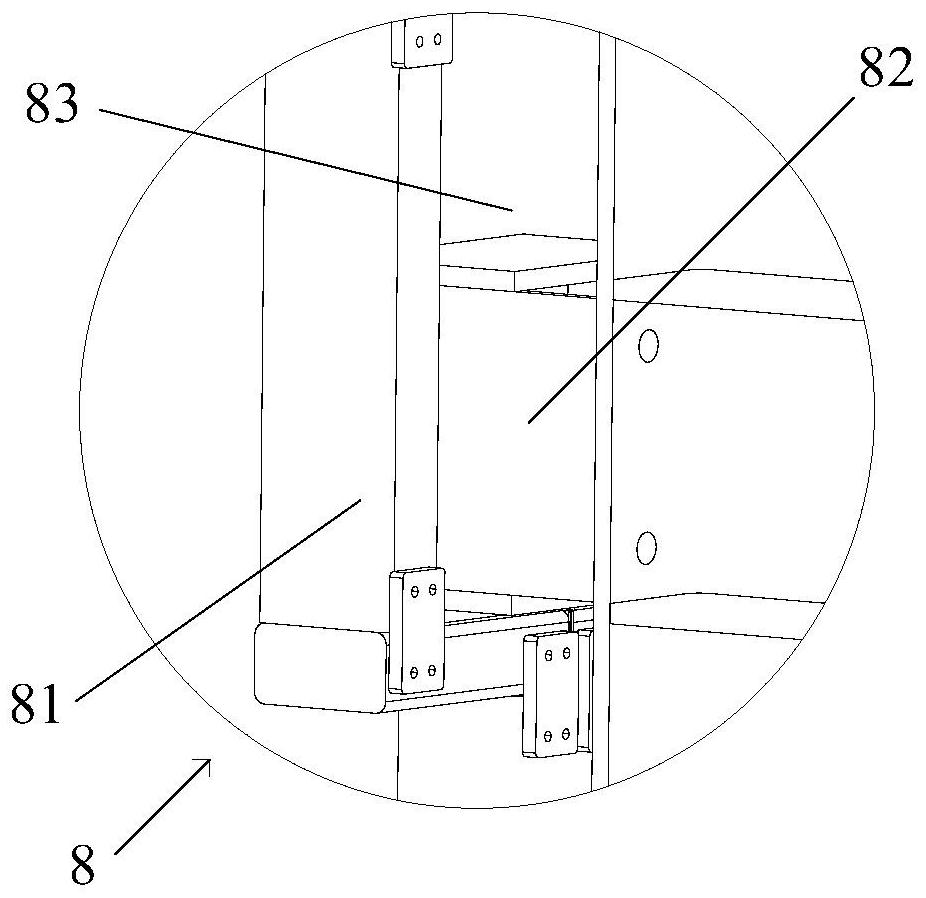

[0031] Such as Figure 1-7 As shown, a multi-functional combustion test furnace shown in this embodiment includes a test furnace body 1, a cover plate 2, a gantry frame 3, two connecting pieces 4 and is used to fix the cover plate 2 on the test furnace body 1 A fixed assembly 5, one end of the two connectors 4 are respectively connected to the two inner sides of the gantry frame 3, and the other ends of the two connectors 4 are respectively slidably connected to the two outer sides of the test furnace body 1; The test furnace body 1 is also provided with a delivery assembly 6 for conveying air and fuel, an air outlet (not shown in the figure) for exhausting exhaust gas, and an exhaust gas treatment assembly 7 for treating exhaust gas. The test furnace body 1 is provided with several thermocouples.

[0032] Based on the above-mentioned structure, the setting of the portal frame 3 increases the overall weight of the test furnace, which leads to the problem of complicated constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com