Welding arc striking burst detection method and system and welding method

A welding arc ignition and detection method technology, which is applied in welding equipment, arc welding equipment, continuity testing, etc., can solve the problem that it is difficult for welders to distinguish bursts, and achieve accurate burst judgments, quantifiable burst judgments, and strong adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

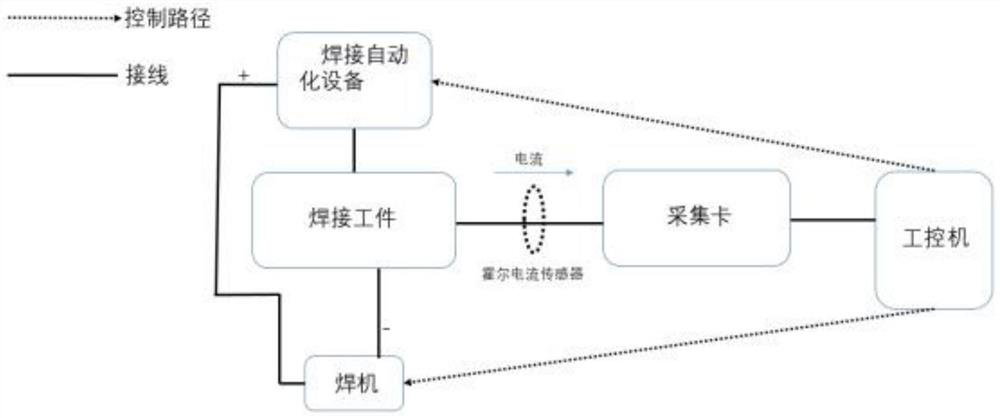

[0057] This embodiment provides a detection system for welding arc ignition explosion, including an acquisition card and an industrial computer. The acquisition card is connected to the welding workpiece and transmits the current data to the industrial computer. The industrial computer implements the method described in Embodiment 1. The detection method of welding arc burst.

Embodiment 3

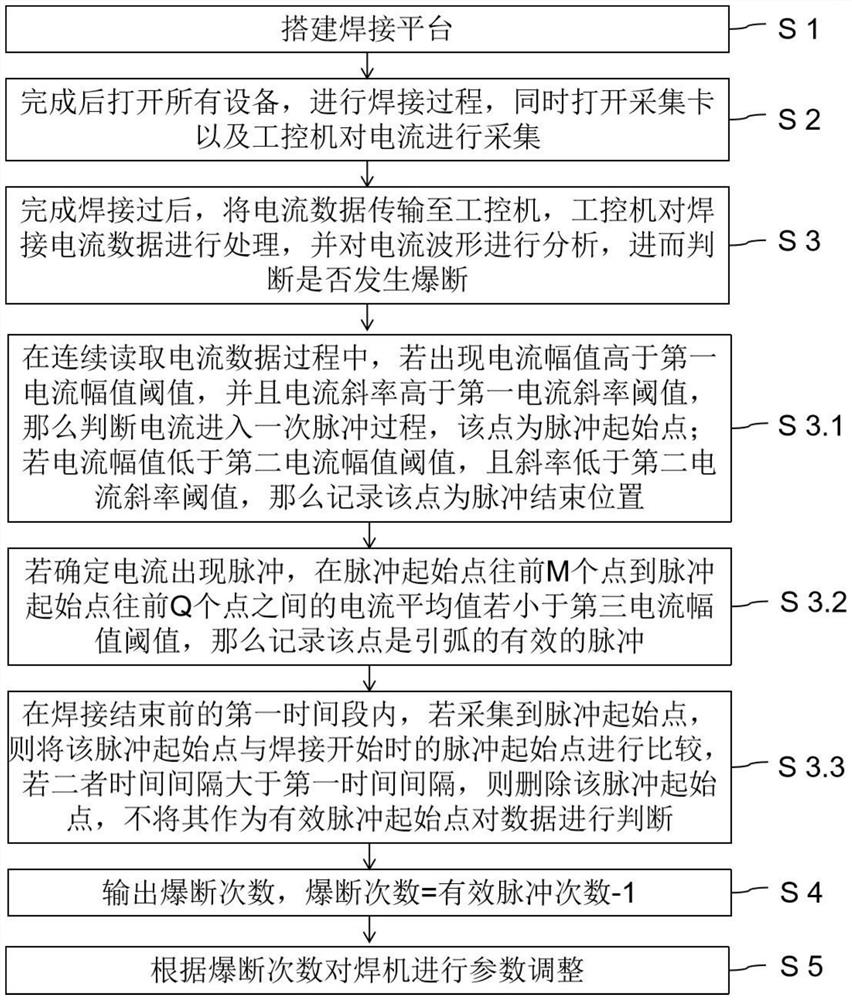

[0059] The present invention also provides a welding method, which is to perform burst detection on the arc striking process before normal welding; the burst detection method adopts the detection method of welding arc burst described in Embodiment 1;

[0060] If the result shows that there is no burst, proceed to the normal welding procedure directly;

[0061] If the result shows that there is a burst during the arc ignition process, adjust the welding process parameters and perform the burst detection during the arc ignition process again; repeat the adjustment of the welding process parameters and the burst detection during the arc ignition process until the result shows that there is no burst and then enter the normal state Welding procedure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com