A cost-optimized in-plant logistics distribution method

A logistics distribution and cost technology, applied in the field of logistics, can solve problems such as increased distribution costs, small quantity of single-product products, and subjective payment order of users that cannot reflect objective needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

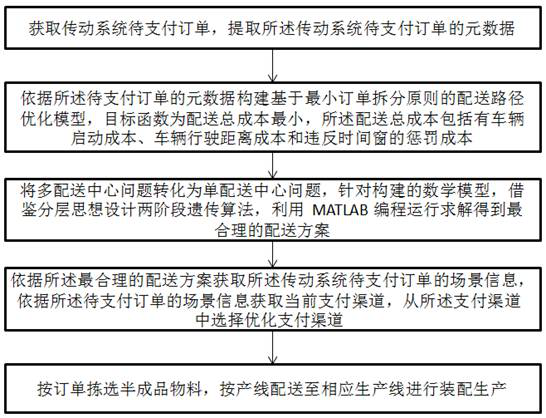

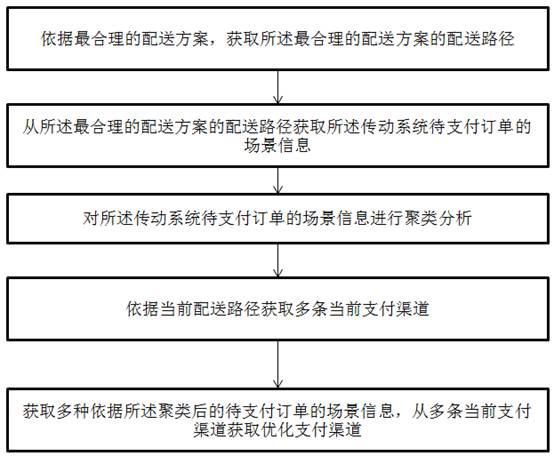

[0034] Illustrative embodiments of the present application include, but are not limited to, a cost-optimized in-plant logistics distribution method.

[0035] It is to be understood that, as used herein, terms; modules; units; may refer to or include application specific integrated circuits (ASICs), electronic circuits, processors (shared, dedicated, or group) executing one or more software or firmware programs ) and / or memory, combinatorial logic, and / or other suitable hardware components that provide the described functionality, or may be part of such hardware components.

[0036] It can be understood that, in various embodiments of the present application, the processor may be a microprocessor, a digital signal processor, a microcontroller, etc., and / or any combination thereof. According to another aspect, the processor may be a single-core processor, a multi-core processor, etc., and / or any combination thereof.

[0037] It can be understood that a cost-optimized in-plant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com