40.5 kV vertical open-type disconnecting switch

An isolating switch and open-type technology, which is applied in the direction of electric switches, air switch parts, high-voltage air circuit breakers, etc., can solve the problems of difficult material selection and increased strength requirements of transmission parts, and achieve stable and reliable transmission, flexible and controllable operation And the effect of stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

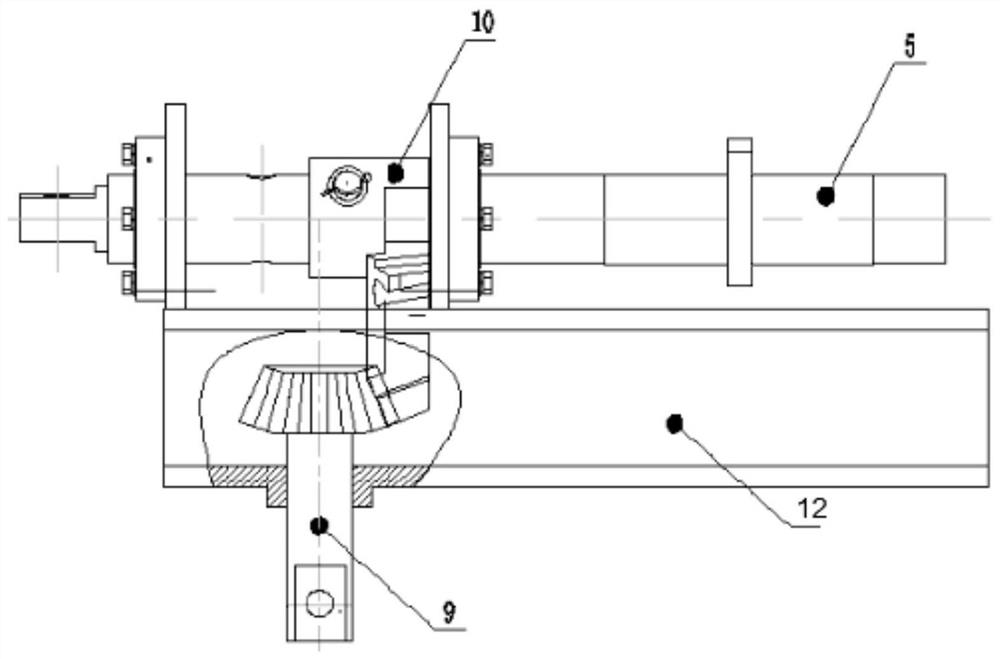

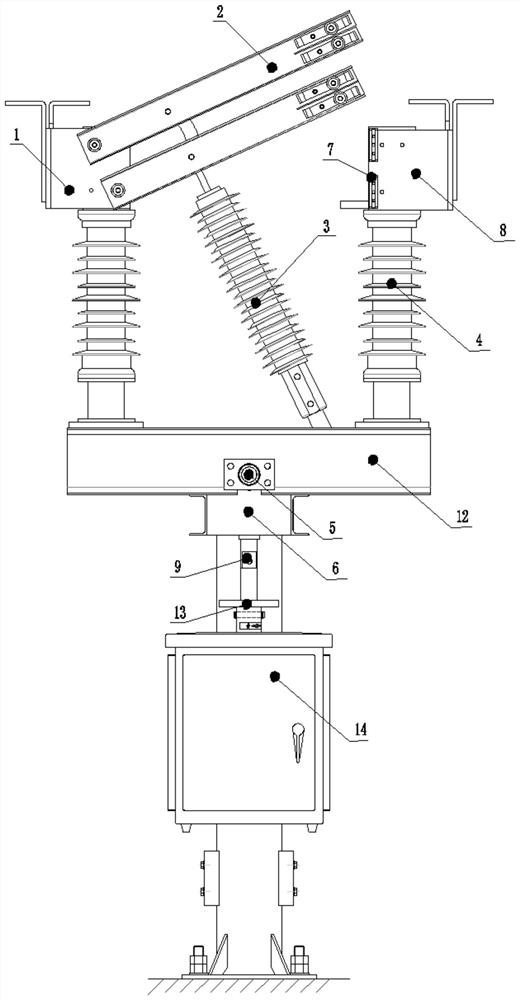

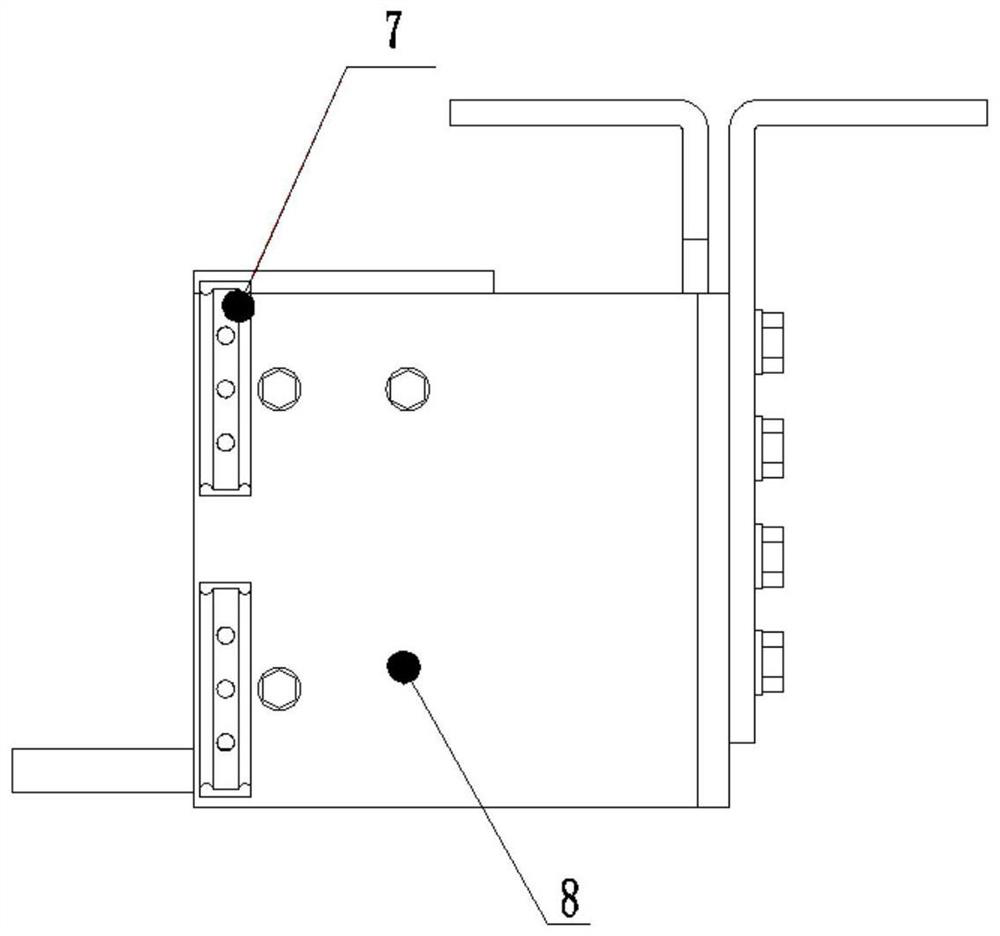

[0025] refer to Figure 1-Figure 4 As shown, the present invention provides a 40.5kV vertical opening type isolating switch, including a base frame 12, on which a plurality of pairs of support insulators 4 and a main conductive base 1 are installed side by side, and a static side base is fixedly installed on the support insulator 4 8. It also includes a transmission box 6, a double-layer conductive arm 2, a transmission insulator 3 and a driving mechanism. One end is articulated, and the drive mechanism includes a plurality of transmission crank arms 5, which are fixedly connected to each other. The other end of the transmission crank arm 5 is hinged to the transmission insulator 3, and the transmission crank arm 5 is used to control the transmission insulator 3. Turn to control the double-layer conductive arm 2 and the static side base 8 to open and close in the vertical direction. When the double-layer conductive arm 2 contacts the static side base 8, it is in the closing st...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the drive mechanism is a horizontal transmission structure, which includes a bidirectional cylindrical motor 11, two drive shafts are provided at both ends of the bidirectional cylindrical motor 11, and the bidirectional cylindrical motor 11 is fixedly installed on the chassis 12 , the two drive shafts of the two-way cylindrical motor 11 are fixedly connected to the transmission crank arms 5 on both sides respectively. Compared with the vertical transmission structure, this structure uses fewer structures, so it reduces the floor space and is suitable for installation It is used underground in places with high area requirements, but compared with the vertical transmission structure in Embodiment 1, the service life of this structure is not as high as that of the vertical transmission structure, and regular maintenance is required. Therefore, the transmission structure can be selected according to the actual s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com