Method for electrical coupling of battery cells of battery module, and battery module

An electrical coupling, battery module technology, applied in electrical components, battery pack components, circuits, etc., can solve the problems of reducing heat dissipation power loss on electrical contact surfaces, reducing manufacturing costs, increasing electrical contact surfaces, and simplifying device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

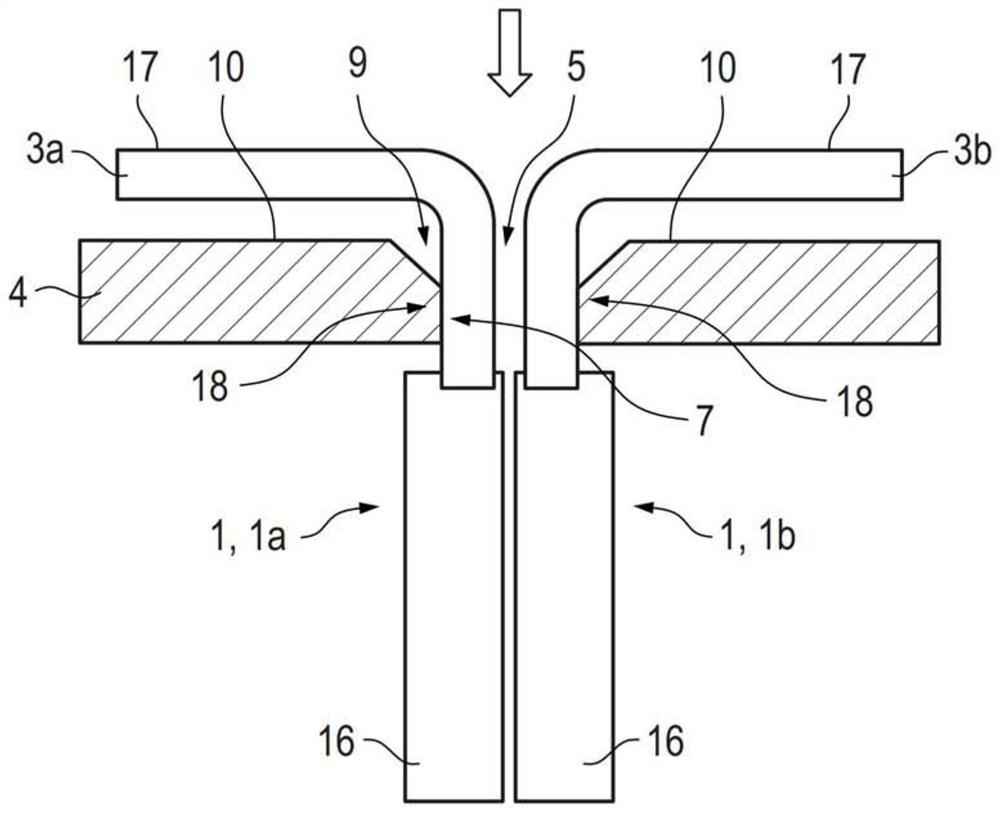

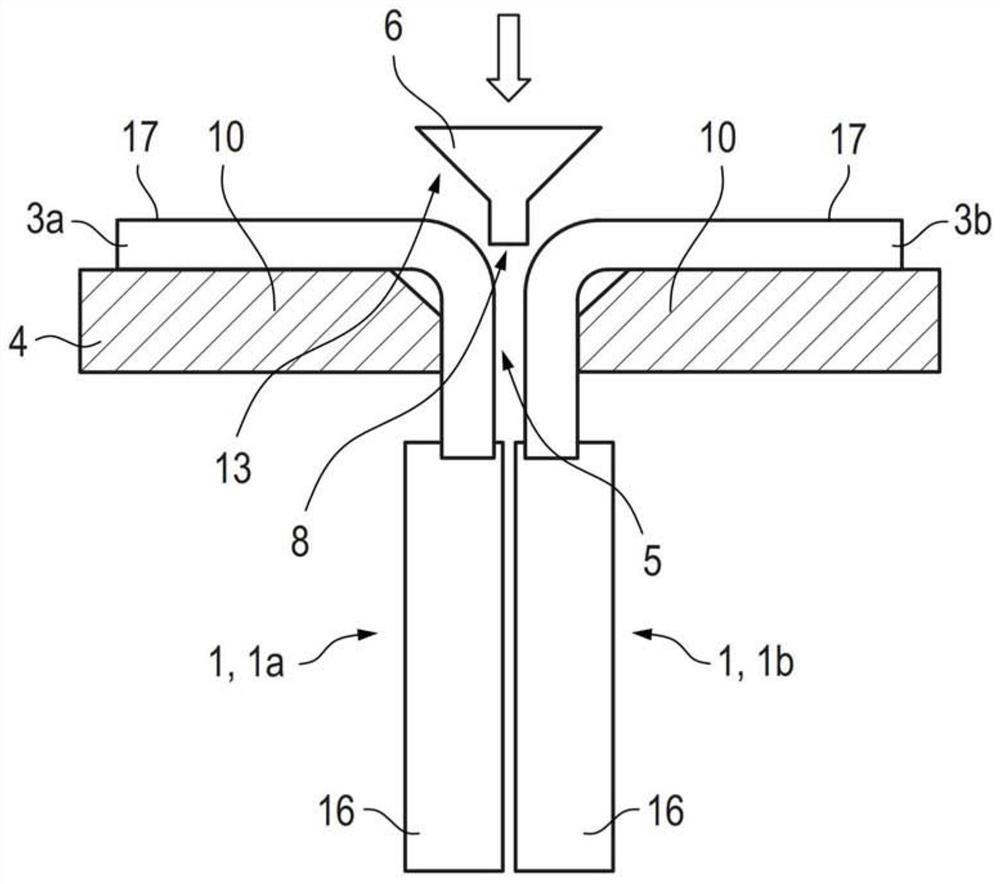

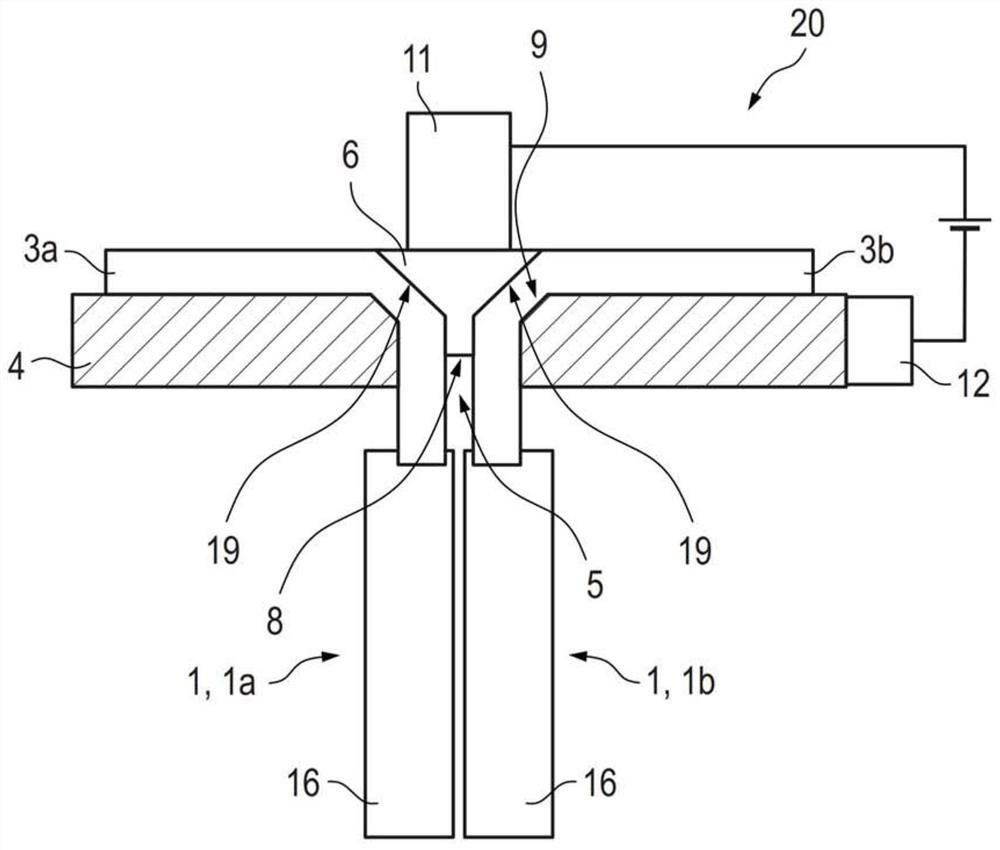

[0039] exist figure 1 A first state during the implementation of a preferred embodiment of the method according to the invention is shown schematically in a side view. In the first state, the two battery cells 1 , namely the first battery cell 1 a and the second battery cell 1 b are arranged on the conductor rail 4 in such a way that the first cell lugs 3 a of the first battery cell 1 a are and the second cell tabs 3b of the second battery cell 1b protrude through the perforations 5 of the conductor busbar 4 . Furthermore, the battery cells 1 each have active components 16 , wherein the active components 16 are all arranged on the same side of the conductor rail 4 . The first cell tab 3a and the second cell tab 3b each have a first end region 17 pointing away from the active component 16 and a second end region 18 leading into the active component 16, wherein the The one end region 17 and the second end region 18 are basically arranged on different sides of the conductor rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com