Processing method of tea raw material for tea beverage, tea leaves and application of tea leaves

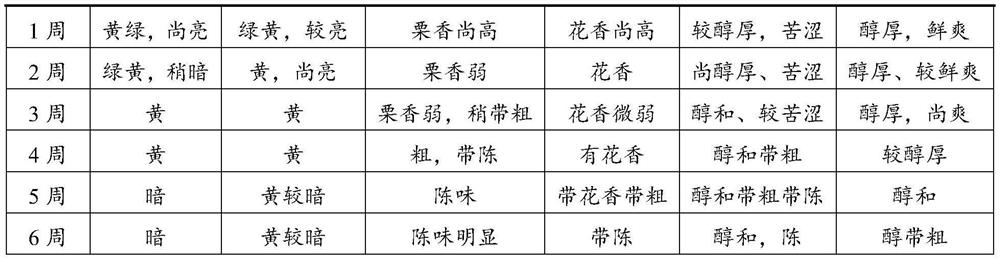

A processing method and technology for tea beverages, which are applied in the field of processing tea raw materials for tea beverages, can solve the problems of weak aroma, bitter taste, waste of tea in summer and autumn, and achieve the effects of green-yellow soup color, mellow taste and full floral fragrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The method for processing tea raw materials for tea beverages in this example includes sequentially low-temperature stimulating fresh tea leaves, calling green to lock freshness, activating and imparting aroma, killing greens, kneading and drying to obtain tea raw materials for tea beverages. Each step is as follows:

[0045] 1. Picking fresh tea leaves

[0046] The fresh tea leaves in this example are preferably high-flavored tea varieties, specifically the variety of Shilixiang tea tree. The picking time is the machine-picked fresh leaf raw materials in summer and autumn. host.

[0047] 2. Low temperature stimulation

[0048] Pile the picked fresh tea leaves in a low-temperature environment to promote the low-temperature stress stimulation treatment of the active ingredients in the fresh tea leaves. Specifically in this example, with a stacking thickness of 20 cm, they were stimulated at low temperature for 30 hours in a cold storage at 8°C.

[0049] 3. Huan Qing ...

Embodiment 2

[0060] The tea raw material processing method for the tea beverage of this example is the same as in Example 1, except that the specific parameters of each step are changed, as follows:

[0061] 1. Picking fresh tea leaves

[0062] The fresh tea leaf of this example is identical with embodiment 1.

[0063] 2. Low temperature stimulation

[0064] Specifically in this example, with a stacking thickness of 10 cm, low-temperature stimulation was performed in a cold storage at 12°C for 8 hours.

[0065] 3. Huan Qing Suo Xian

[0066] Specifically in this example, the green leaves are placed in a closed environment with a humidity of 75% at 30° C., placed to make the tea leaves soft, and the temperature of the green leaves rises to the ambient temperature. Huanqing Suoxian can accelerate the biochemical reactions inside the green leaves, making the green leaves soft and ready for the next step.

[0067] Further in this example, after being placed in a temperature-controllable an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com