Pipeline connecting structure and endoscope smoke circulating system

A technology for connecting structures and pipelines, which is applied in the field of medical devices and can solve the problems of complex connection methods of gas pipelines and increased operation time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

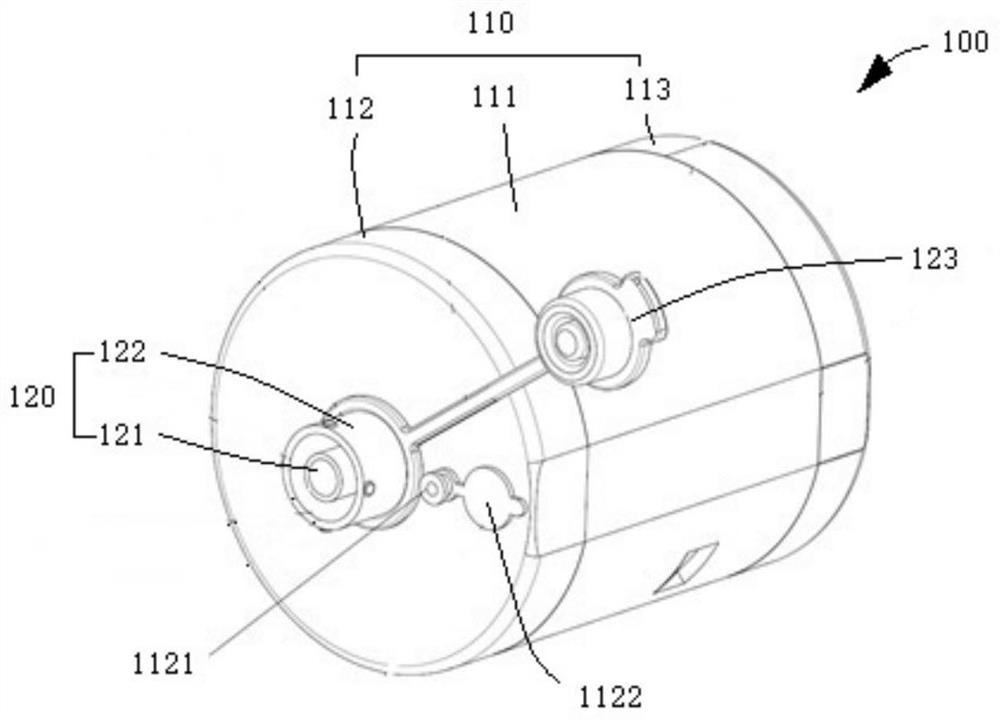

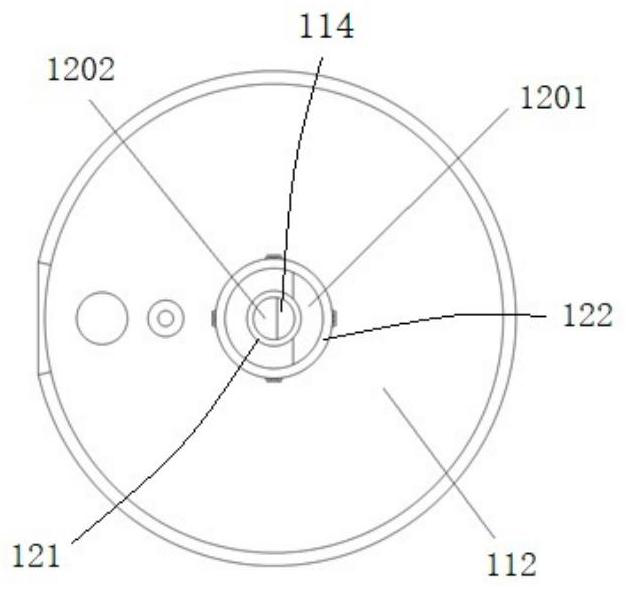

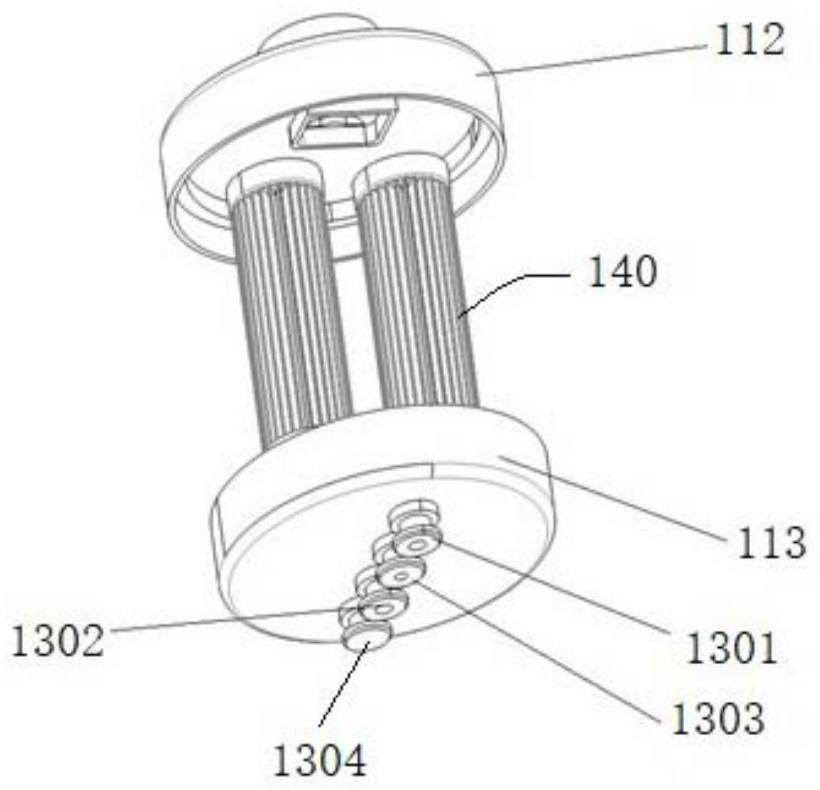

[0056] Such as Figure 1 to 4 As shown, the filtration device 100 includes:

[0057] A filter housing 110, the filter housing 110 has a filtration gas chamber 1101 and a filtration exhaust chamber 1102 with each other.

[0058] A first connecting assembly 120, the first connection assembly 120 is disposed at one end of the filter housing 110 having an air outlet portion 1201 and a plurality of exhaust portions 1202, the air supply inlet portion 1201 and The filtering gas chamber 1101 communicates with the filter exhaust line 1102;

[0059] A second connection assembly 130, the second connection assembly 130 is disposed at the other end of the filter housing 110 in such a manner that departing from the first connection assembly 120, which has an air supply inlet portion 1301 and a distant smoke. The exit portion 1302 is in communication with the filtration input unit 1101, the exhaust port portion 1302 in communication with the filter exhaust chamber 1102;

[0060] At least one filt...

no. 2 example

[0086] Such as Figure 9 As shown, the filter device 100 of the second embodiment differs from the first embodiment in that the filter device 100 further includes a plurality of adapter 160, the multi-adapter 160 being disposed in the first connection assembly 120. Up to facilitate the pipe connection.

[0087] Such as Figure 10 As shown, the plurality of adapter 160 includes a cardiac joint 161, a gas contact 162, and a row of smoke joint 163, including a joint inner tube 1611 and a joint outer tube 1612 from the inner except. The venting joint 162 is coupled to an area incorporated between the joint inner tube 1611 and the joint outer tube 1612, the exhaust joint 163 communicates into a region enclosed in the inner tube 1611. The venting joint 162 and the exhaust joint 163 are arranged in a V-type to enable the multi-adapter 160 as a y.

[0088] It can be seen that the multi-adapter 160 can be inserted to be arranged on the first connection assembly 120, reference figure 1 and Fi...

no. 3 example

[0092] Such as Figure 11 to 14 As shown, the filtration device 100 of the third embodiment differs from the first embodiment in that the filter device 100 further includes a plurality of adapter 160 and a joint cover 170, the plurality of adapter 160 through the joint The compression cover 170 is fixed to the first connection assembly 120 to connect the multipirement, and each realize the function of the pressure, exhaust, drain, and regulator.

[0093] Such as Figure 11 and Figure 13 As shown, the multi-adapter 160 includes a joint fixing plate 166, and a gas joint 162 provided on the joint fixing plate 166, a tunnel joint 163, a shunting joint 164, and two reserved connections. 165, but not limited thereto, can be selected according to the actual needs.

[0094] Such as Figure 11 As shown, the first connection assembly 120 of the third embodiment differs from the first embodiment in that a plurality of connecting tubes 124 are plugged in, and the plurality of connect tube 124 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com