Focused ion beam sample cleaning method and device

A technology of focusing ion beam and cleaning device, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to effectively clean focused ion beam samples, and achieve the effect of improving cleaning effect and improving picture quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

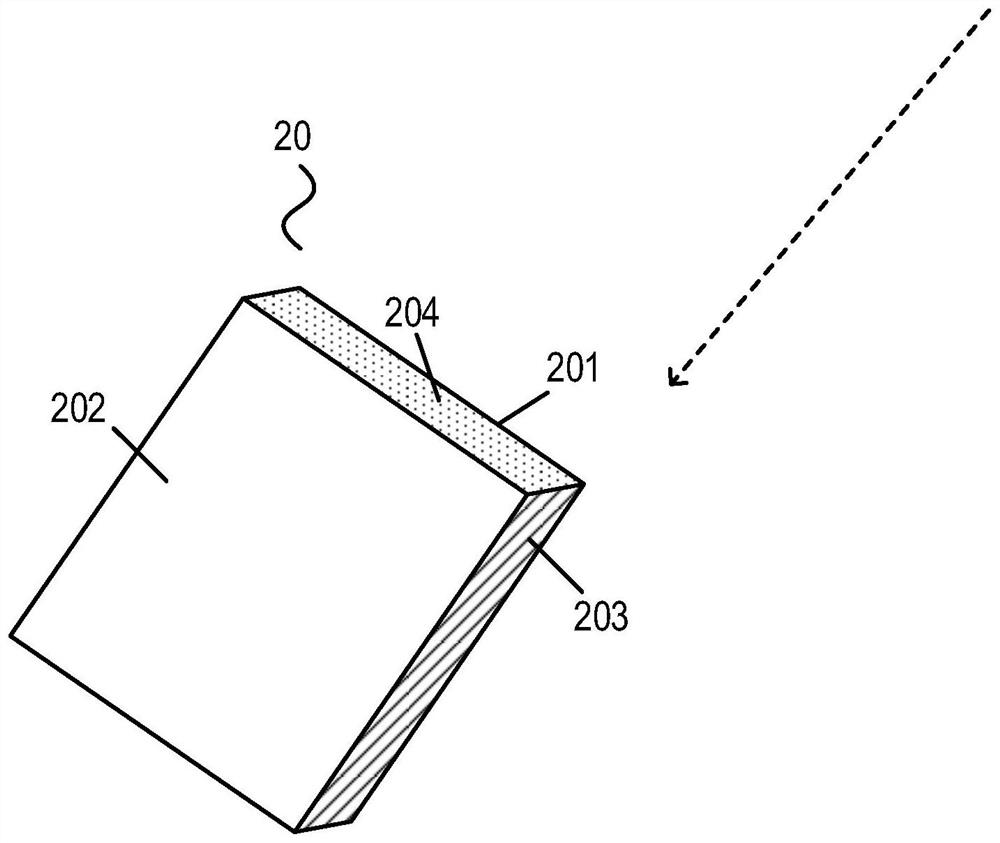

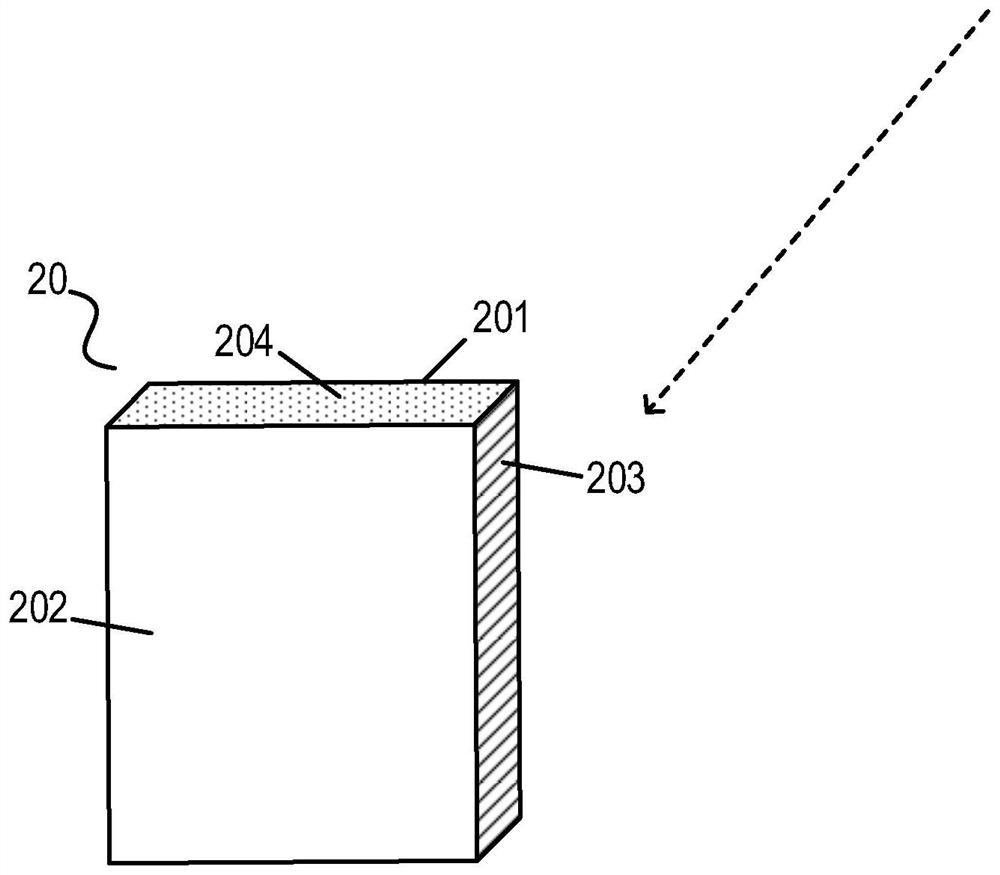

[0048] The specific implementation of the focused ion beam sample cleaning method and device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] At present, when low-voltage ion beams are used to clean impurities such as redeposits and amorphous layers on the surface of the focused ion beam, the angle caused by the sticky sample during the focused ion beam sample preparation process, such as the prepared focused ion beam sample and the grid The relationship between the grid fingers is not parallel or perpendicular to each other, so that part of the surface of the focused ion beam sample cannot be in contact with the ion beam during the cleaning process, so that it cannot be cleaned, which reduces the cleaning effect of the focused ion beam sample.

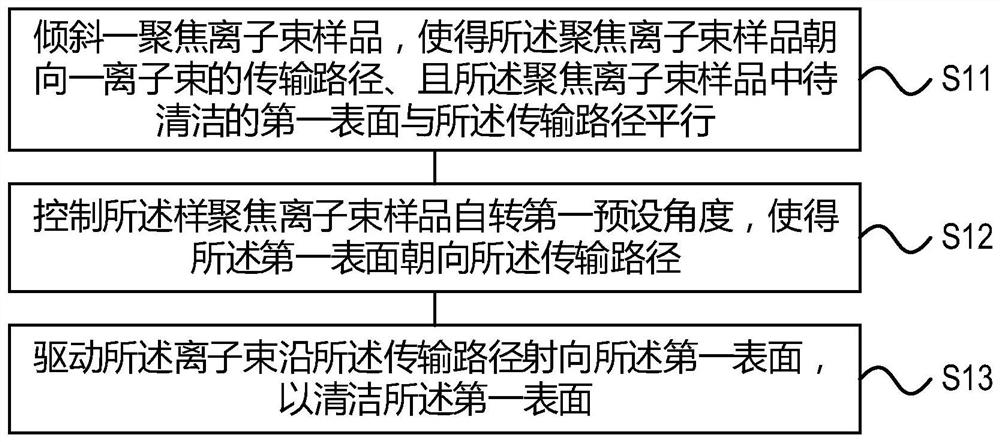

[0050] In order to improve the cleaning effect of focused ion beam samples, this specific embodiment provides a focused ion beam sample cleaning method, with f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap