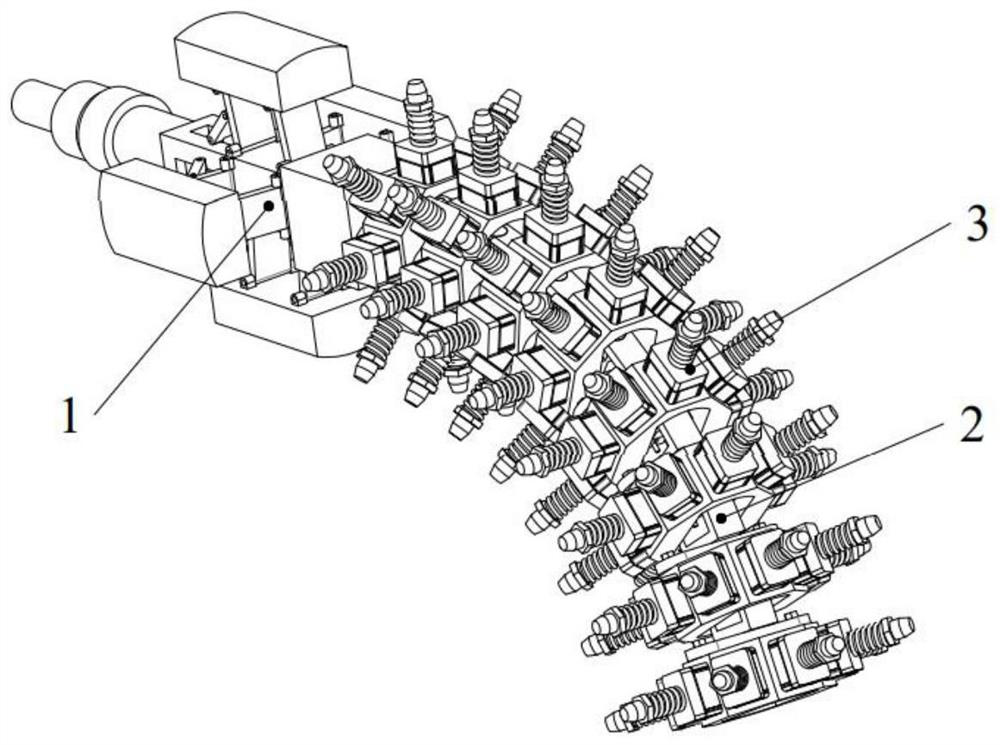

Multi-sensor fusion pipe fitting bending forming state real-time monitoring device

A multi-sensor fusion and bending forming technology, applied in the field of pipe bending and forming, to achieve the effect of intelligent detection and comprehensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

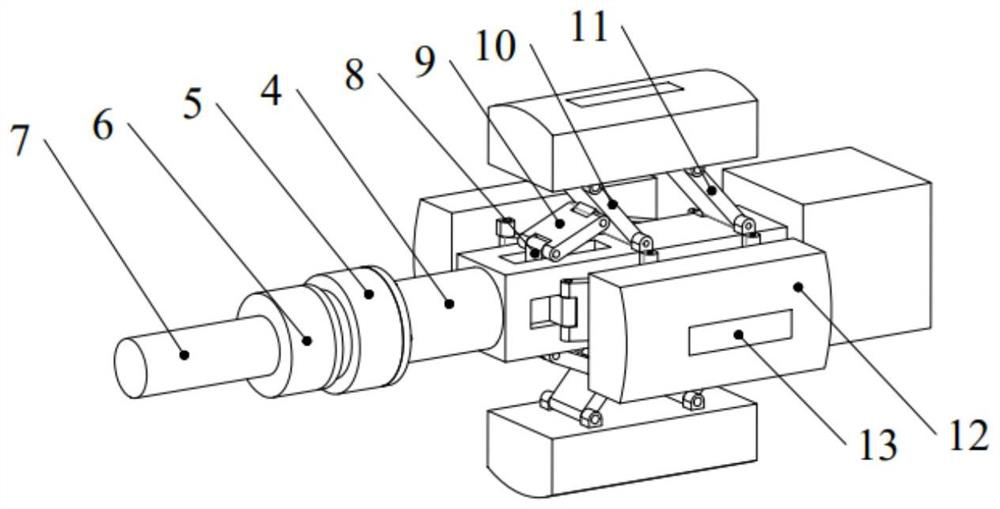

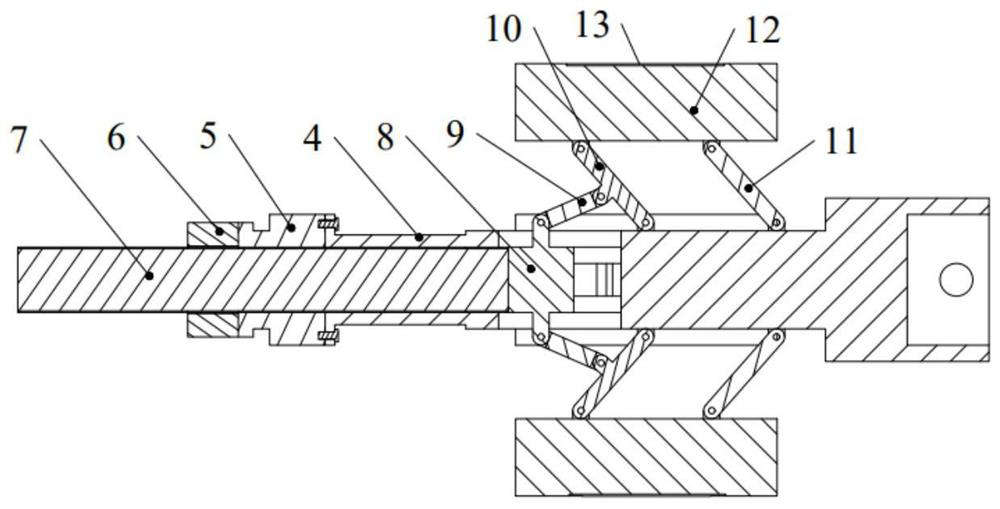

specific Embodiment approach

[0052] (1) if Figure 14 As shown, the joint yoke of the quick disassembly universal joint 2 is fixed to the support frame 14 of the bending state detection module 3 through bolts for use, and an appropriate number of bending state detection modules 3 is selected according to the length of the pipe bending section.

[0053] (2) Take one of the quick disassembly universal joints 2 installed together with one of the bending state detection modules 3, and manually or use tools to make the two toggle pins on the cross axis 18 of the quick disassembly universal joint 2 in the direction of the horizontal axis 21 to move inward, so that the slider II 19 moves inward against the force of the return spring 20 and retracts into the hole, inserts the cross shaft 18 into the groove of the support frame 14 of the bending state detection module 3, loosens the toggle pin 21, and makes Under the action of the return spring 20, the slider II19 is inserted into the limiting counterbore on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com