Cold stamping springback control die

A technology of cold stamping and mold, which is applied in the field of cold stamping control springback mold, which can solve the problems of large friction, scratches on the second horizontal plate, difficult deflection of the vertical part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

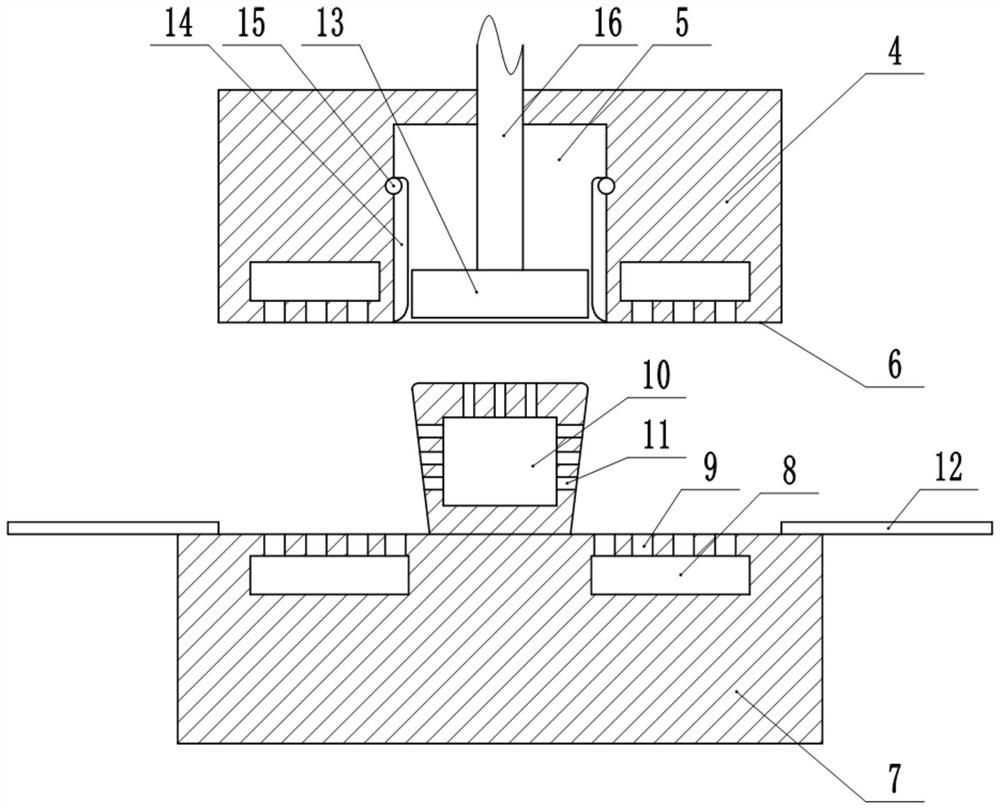

[0018] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

[0019] like image 3 As shown, the cold stamping control rebound die includes a frame, and the frame is provided with a punch 7 and a die 4 that cooperate with each other. In the present embodiment, the die 4 is located above the punch 7, and the die 4 is a dynamic The mold, that is, the punch 7 is fixedly arranged on the frame, and the die 4 is slidably connected to the top of the punch 7, and the punching is completed by sliding the die 4. Both the male mold 7 and the female mold 4 include a forming part 5 and horizontal parts 6 located on both sides of the forming part 5, and the forming part 5 includes a horizontal forming surface and side forming surfaces located on both sides of the horizontal forming surface.

[0020] The two side molding surfaces of the die 4 are rotatably connected to the side away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com