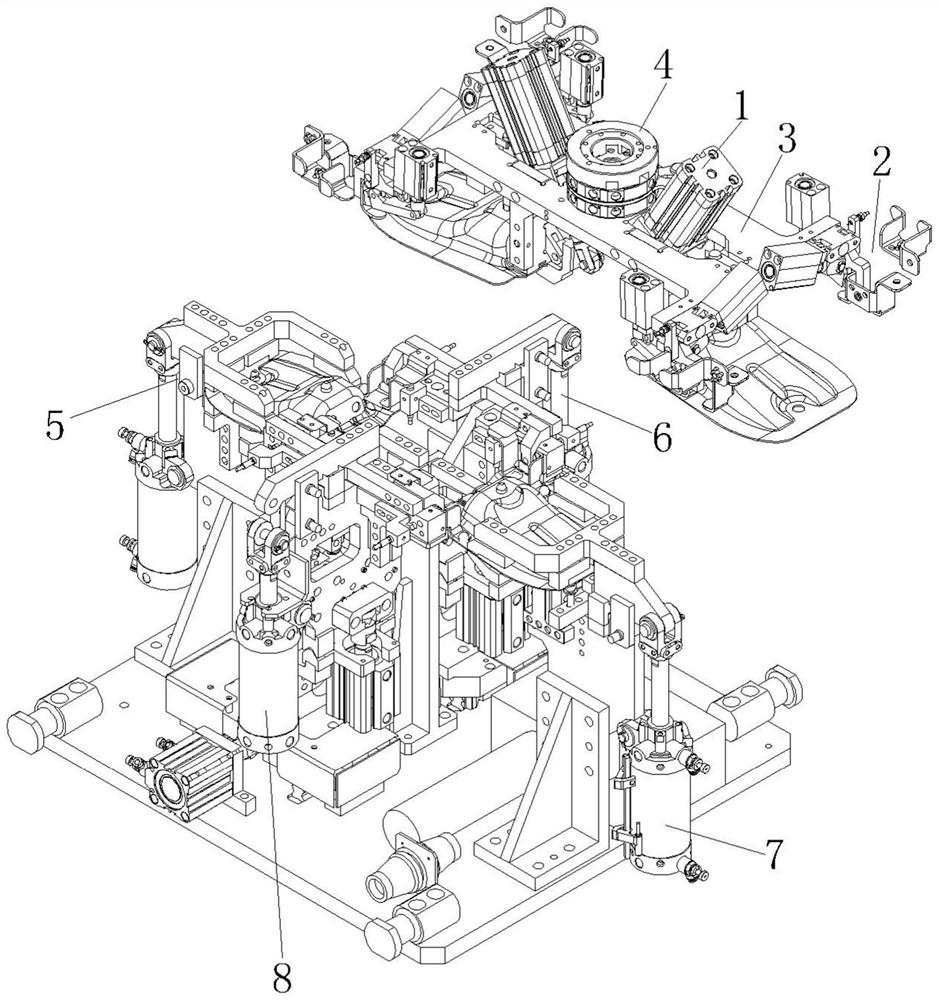

Welding clamp and matched feeding and discharging tool thereof

A welding fixture and tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, high repetitive labor intensity, limited time saving, etc., and achieve high clamping work efficiency, The effect of improving work efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] Embodiment 2. On the basis of the technical solution of Embodiment 1, the specific structure of the first clamping mechanism 5 of the welding fixture of the present invention is that the first support plate 53 is vertically arranged on the base 9, and the first support plate 53 is vertically arranged on the base 9. The plate 53 includes a vertical plate and a horizontal plate, and the first cylinder 51 is rotatably connected to the side of the first supporting plate 53 , that is, the side of the vertical plate, through the mounting seat. Further, the opening on the side of the first support plate 53, that is, the opening on the upper side of the riser, the mounting seat of the first cylinder 51 is connected to the side opening of the first support plate 53 through a pivot, that is, the mounting seat passes through Pivot to the side opening of the side panel.

[0036] Further, the telescopic shaft of the first cylinder 51 is pivotally connected to the pivot hole opened o...

Embodiment 3

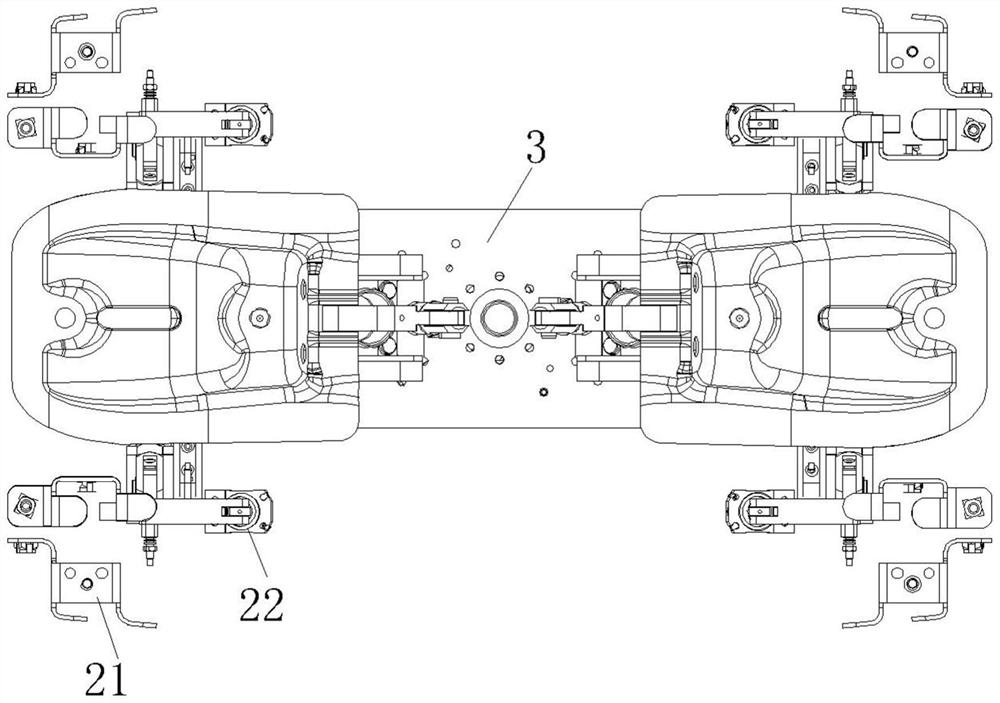

[0037] Embodiment 3, on the basis of the technical solution of Embodiment 2, the welding fixture of the present invention, the specific structure of the second clamping mechanism 6 is that the second support plate 64 is vertically arranged on the base 9, and the second cylinder 61 is pivotally connected to the side hole of the second support plate 64 . Further, the telescopic shaft of the second air cylinder 61 is pivotally connected to the pivot hole provided on the second clamping plate 63 . Further, the upper end of the second rocking plate 62 is rotatably connected to the second clamping plate 63 through a pin shaft, and the lower end of the first rocking plate 54 is rotatably connected to the top of the second support plate 64 through a pin shaft. Since the bent plate 21 is a bent plate 21 with a small structural size, the bent plate 21 can be clamped on the second clamping plate 63 by positioning pins and bolts, and the bent plate 21 is placed on the shell member 16 The...

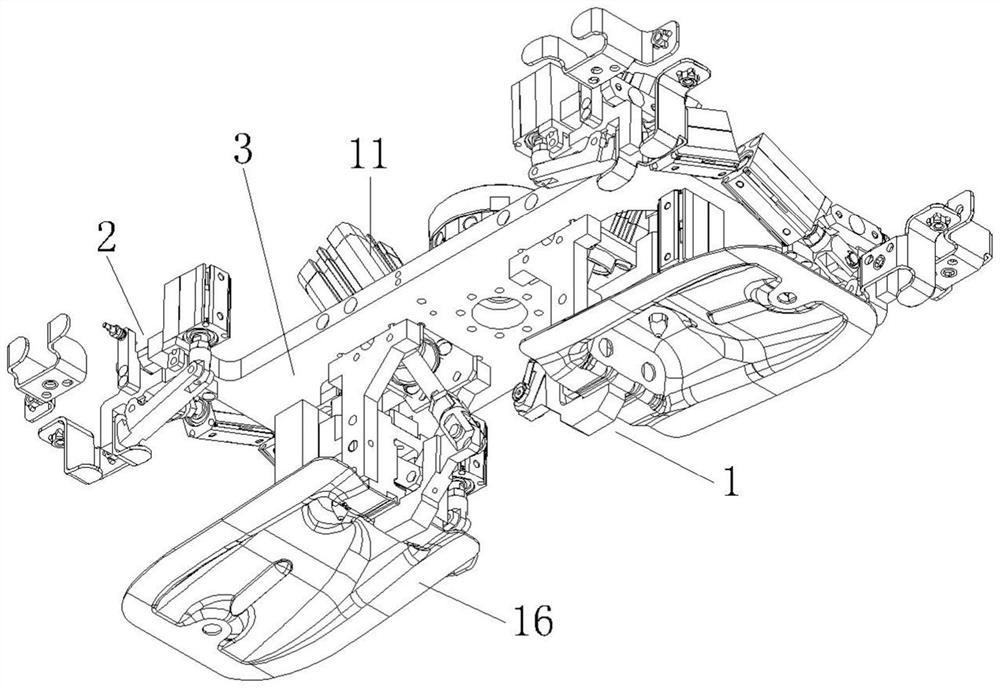

Embodiment 5

[0042] Embodiment five, such as Figure 1-4 As shown, on the basis of the technical solution of Embodiment 4, the specific structure of the first gripper 1 of the loading and unloading tooling of the present invention is that the first cylinder 11 is installed obliquely, the second cylinder 12 and the first support plate 15 are arranged perpendicular to the base plate 3 , the ejector rod 17 is arranged parallel to the first support plate 15 , and the ejector rod 17 withstands the middle part of the shell member 16 . The first cylinder 11 is hinged to the splint 13 through the telescopic shaft, and the angle between the telescopic shaft and the push rod 17 is an acute angle, and the specific angle parameters are set according to actual production needs. Both ends of the third rocking plate 14 are respectively hinged to the first supporting plate 15 and the splint 13 . The two ends of the third rocking plate 14 are hinged, and the movable plate 24 is equivalent to a lever. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com