Automatic wine bottle cap assembling device

An automatic assembly and wine bottle cap technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low safety, time-consuming and labor-intensive manual assembly, and affect the accuracy and efficiency of assembly, so as to ensure accuracy, Effects that improve stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] As a preferred embodiment of the present invention, vent holes 41 are opened on both sides of the fixing seat 30 .

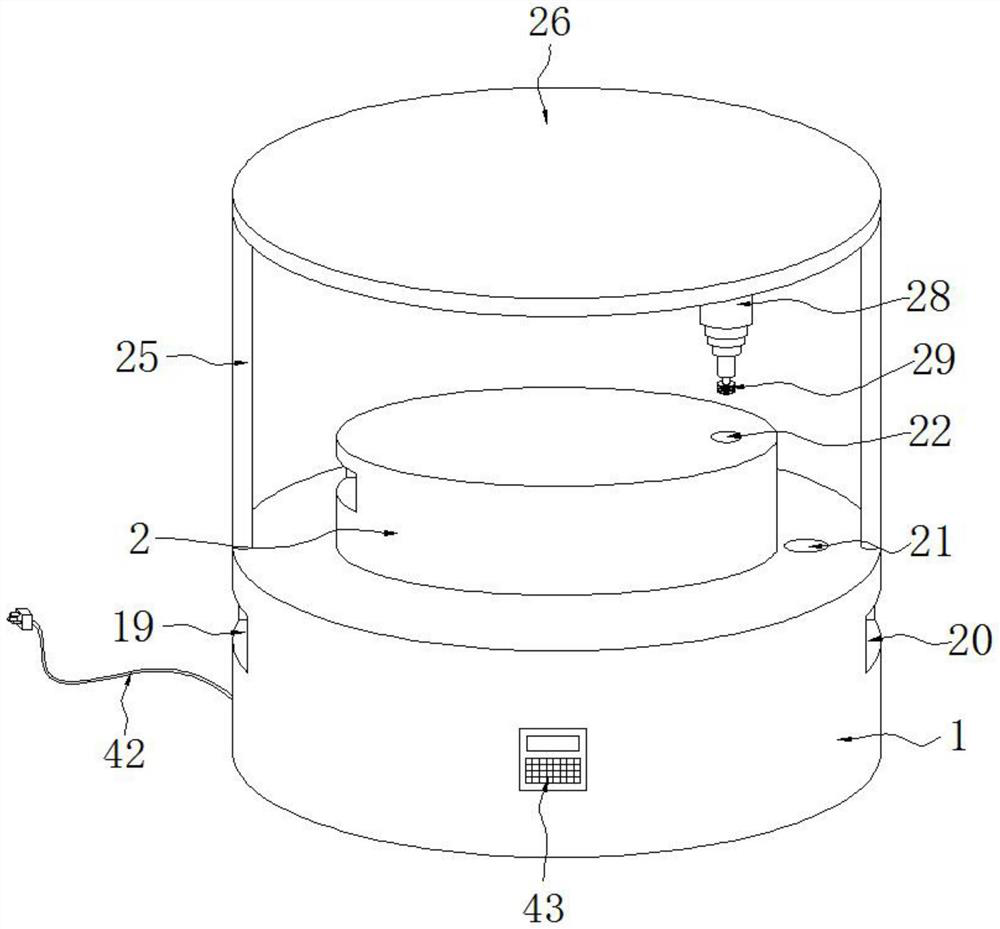

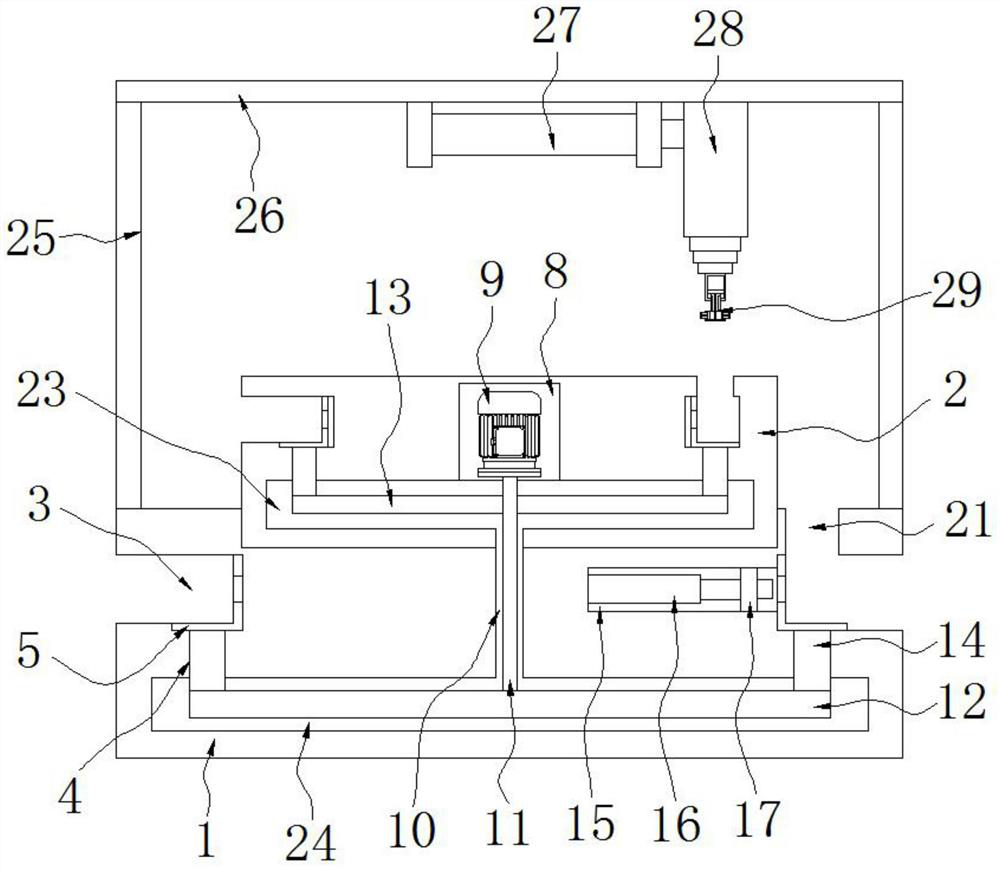

[0028] As a preferred embodiment of the present invention, a control panel 43 is installed on the front side of the cover delivery base 1, a power cord 42 is connected to one side of the cover delivery base 1, and one end of the power cord 42 is connected to There is a plug, and the power cord 42 is electrically connected with the control board 43, the stepper motor 9, the ejection electric push rod 16, the horizontal electric push rod 27 and the multi-stage electric push rod 28, and the control board 43 is connected with the stepper The feed motor 9, the ejection electric push rod 16, the horizontal electric push rod 27 and the multi-stage electric push rod 28 are electrically connected.

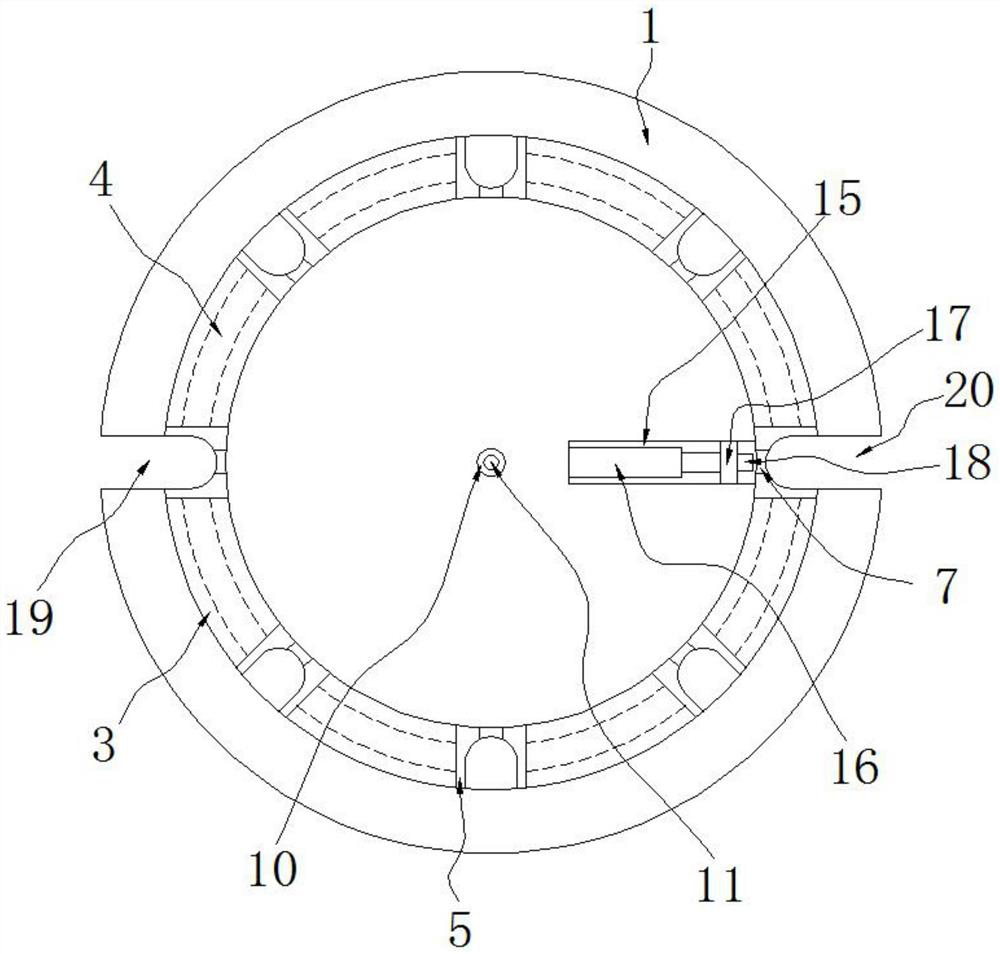

[0029] As a preferred embodiment of the present invention, the number of said curved bottle cap carrying seats 5 is eight.

[0030] As a preferred embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com