Precise trimming device for section of end part of spliced protective fence

A technology of end section and dressing device, which is applied to machine tools suitable for grinding workpiece edges, grinding drive devices, and parts of grinding machine tools, etc. and other problems, to achieve the effect of reducing angle error, good versatility, and improving ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

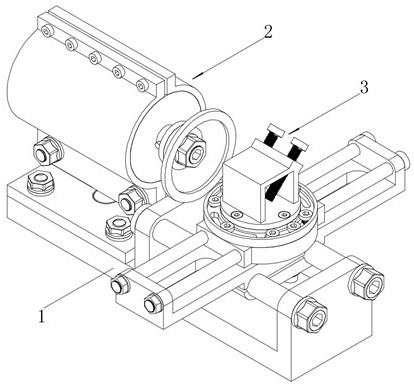

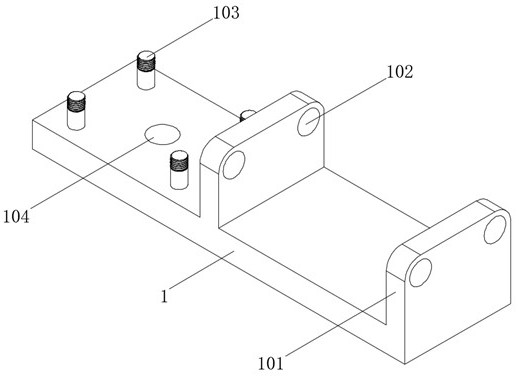

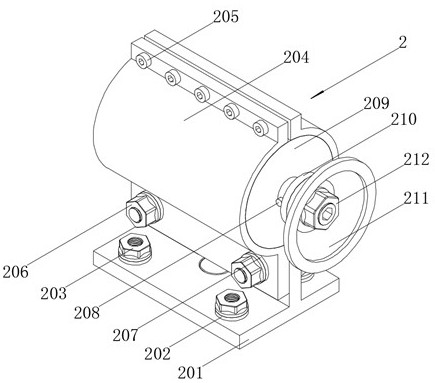

[0040] refer to Figure 1 - Figure 15 A precision trimming device for the end section of the splicing protective bar, including the support assembly 1 and the grinding assembly 2 and the clamp assembly 3 disposed thereon, and two grinding assemblies in the support assembly 1 are vertical. The bottom plate 101, the upper end of the bottom plate 101 opens a bottom plate aperture hole 102, wherein one bottom plate 101 is located at the end of the support assembly 1, and the other end of the support assembly 1 is provided with four vertical bottom bolts 103, support The assembly 1 opens the bottom plate vertical hole 104 at the midpoint of the four bottom bolts 103, the grinding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com