Thelephora ganbajun Zang distilled liquor and preparation process thereof

A production process and drying bacteria technology, which is applied in the field of wine making, can solve the problems of poor taste of wine, and achieve the effect of improving taste, ensuring quality and safety, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In order to solve the problems existing in the existing Ganba bacteria brewed wine, the embodiment of the present invention provides a production process of Ganba bacteria distilled wine, which includes the following steps:

[0028] 1. Production of base liquor: blend the solid-state liquor base liquor into a base liquor with an alcohol content of 50% vol;

[0029] 2. Soaking: Soak the cleaned and dried dried bacteria in the base wine prepared above for 15 days to form a soaking solution containing dried bacteria. The mass ratio of dried bacteria to base wine is 1:100;

[0030] 3. Distillation: After soaking, put the soaking liquid (including soaked dried bacteria) into the still for distillation. The feeding should be uniform around, so that the speed of steaming in the whole still can be kept consistent, and dead ends can be prevented. Gassing, so as not to affect the yield and quality of the wine; after the feeding is completed, cover the lid of the still, and carefu...

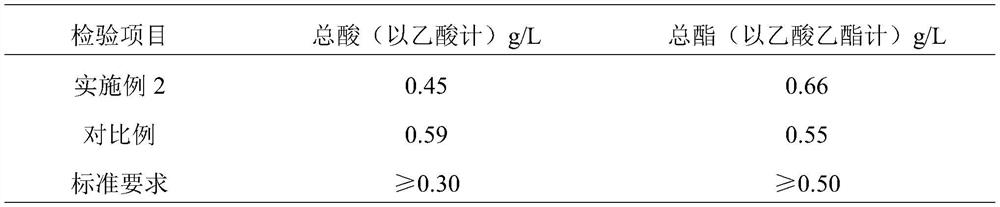

Embodiment 2

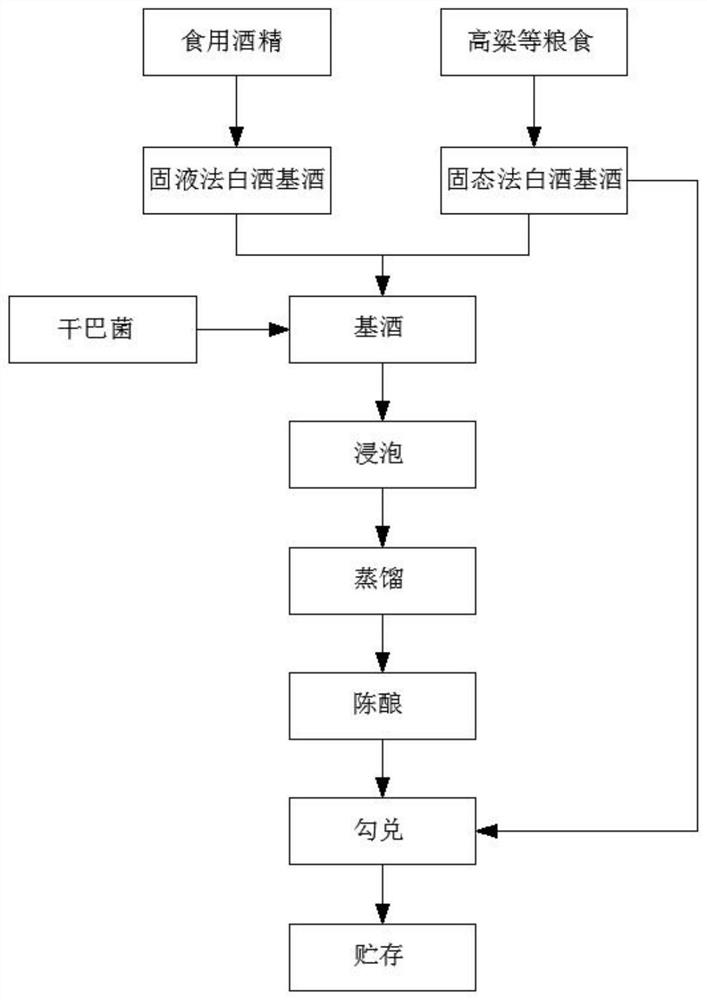

[0036] The production process of Ganba bacteria distilled wine, the process flow chart is as follows figure 1 shown, including the following steps:

[0037] 1. Production of base wine: blending the solid-liquid method liquor base liquor and the solid-state method liquor base liquor at a mass ratio of 2:1 to make a base liquor with an alcohol content of 70% vol;

[0038] 2. Soaking: Soak the cleaned and dried dried bacteria in the base wine prepared above for 200 days to form a soaking solution containing dried bacteria. The mass ratio of dried bacteria to base wine is 2:100;

[0039] 3. Distillation: After soaking, put the soaking liquid into the distiller for distillation. The feeding should be uniform all around, so as to keep the speed of steaming in the whole distiller consistent, prevent dead ends, no gas, and avoid affecting the yield of alcohol The quality of the wine; after the feeding is completed, cover the lid of the distiller, and carefully observe whether there i...

Embodiment 3

[0045] The manufacturing process of Ganba bacteria distilled liquor comprises the following steps:

[0046] 1. Production of the base liquor: blend the solid-liquid method liquor base liquor into a base liquor with an alcohol content of 80% vol;

[0047] 2. Soaking: Soak the cleaned and dried dried bacteria in the base wine prepared above for 365 days to form a soaking solution containing dried bacteria. The mass ratio of dried bacteria to base wine is 3:100;

[0048] 3. Distillation: After soaking, put the soaking liquid into the distiller for distillation. The feeding should be uniform all around, so as to keep the speed of steaming in the whole distiller consistent, prevent dead ends, no gas, and avoid affecting the yield of alcohol The quality of the wine; after the feeding is completed, cover the lid of the distiller, and carefully observe whether there is air leakage around the distiller, the trachea, the sealing ring, etc.;

[0049] Start distillation after checking th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com