Preparation method of high-strength piston pin hole bushing

A piston pin hole and high-strength technology is applied in the field of preparation of piston pin hole bushings, which can solve the problems of low material utilization rate, high production cost and high price, and achieve high material utilization rate, low cost and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] ① Ingredients: Silicon brass is selected as the bushing material; 33% Zn, 2.5% Mn, 1.5% Al, 1.2% Ni, 1.3% Si, and the rest are Cu for weight percentage. Copper, zinc, aluminum and silicon are added in the form of pure copper, pure zinc, pure aluminum and pure silicon, and manganese and nickel are added in the form of CuMn30 copper-manganese master alloy and CuNi15 copper-nickel master alloy.

[0025] ②Smelting: Add pure copper, pure zinc, pure aluminum, pure silicon, copper-manganese alloy and copper-nickel alloy into the melting furnace to melt, and fully stir evenly to prevent uneven temperature of copper liquid and local overheating and oxidation.

[0026] ③Horizontal continuous casting: The smelted copper liquid is subjected to horizontal continuous casting to obtain a copper tube ingot with an outer diameter of 60 mm, an inner diameter of 50 mm and a length of 1000 mm.

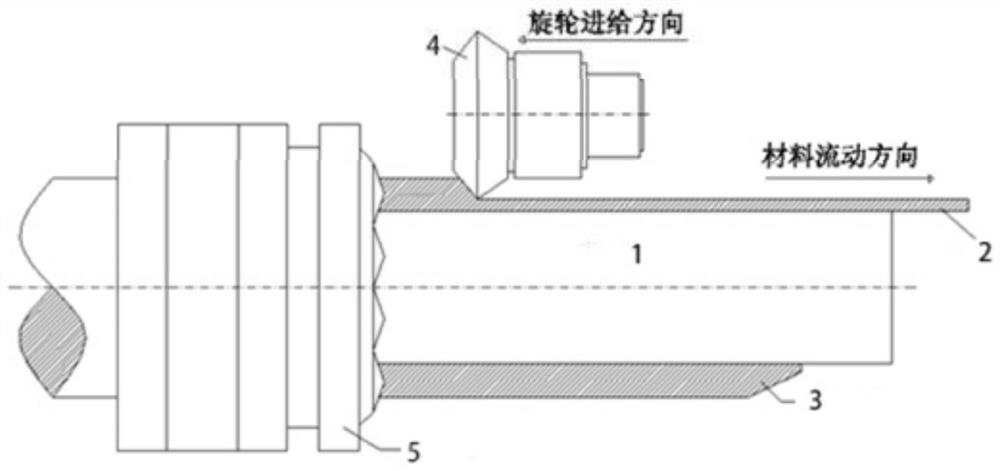

[0027] ④ Spinning: The copper tube ingot obtained after horizontal continuous casting is used a...

Embodiment 2

[0031] ① Batching: 29% Zn, 1.5% Mn, 0.8% Al, 0.6% Ni, 0.8% Si, and the rest are Cu in weight percentage. Copper, zinc, aluminum and silicon are added in the form of pure copper, pure zinc, pure aluminum and pure silicon, and manganese and nickel are added in the form of CuMn30 copper-manganese master alloy and CuNi15 copper-nickel master alloy.

[0032] ②Smelting: Add pure copper, pure zinc, pure aluminum, pure silicon, copper-manganese alloy and copper-nickel alloy into the melting furnace to melt, stir well and evenly to prevent uneven temperature of copper liquid and local overheating and oxidation.

[0033] ③Horizontal continuous casting: The smelted copper liquid is subjected to horizontal continuous casting to obtain a copper tube ingot with an outer diameter of 50 mm, an inner diameter of 40 mm and a length of 1000 mm.

[0034] ④ Spinning: The copper tube ingot obtained after horizontal continuous casting is used as a spinning blank, and the spinning is performed by rev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap