Speed reduction device

A deceleration device and main channel technology, applied in the direction of brake type, brake parts, liquid resistance brake, etc., can solve the problems of low power conversion efficiency, large noise and vibration, etc., to improve power conversion efficiency, improve efficiency, improve The effect of acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

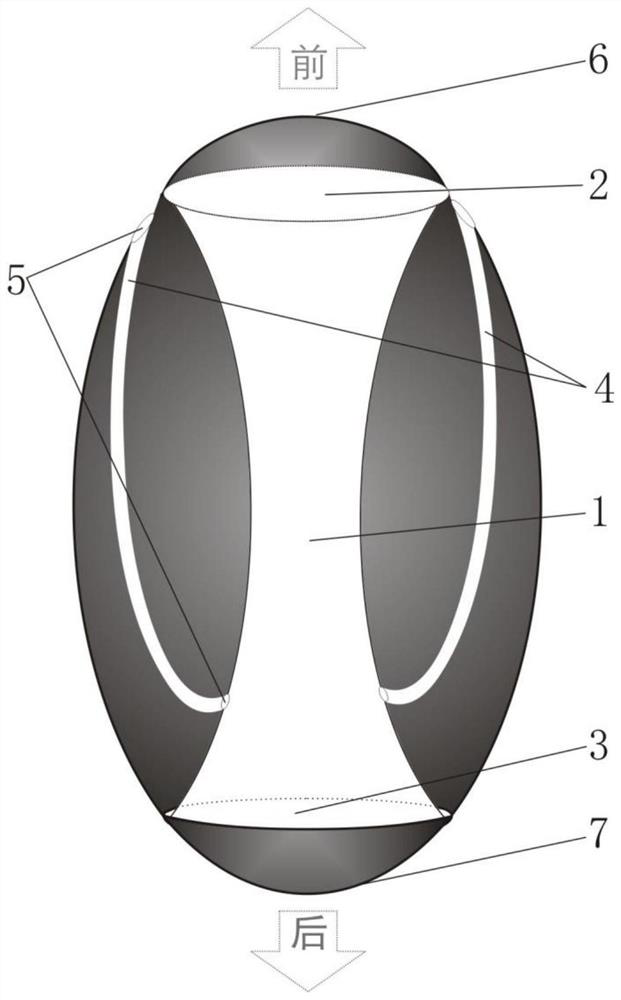

[0030] Such as figure 1 As shown, a deceleration device is the most commonly used deceleration device, including a main channel 1, the main channel 1 forms a front port 2 of the main channel at the front end of the deceleration device, and a rear port 3 of the main channel is formed at the rear end of the deceleration device, and The front port 2 of the main channel and the rear port 3 of the main channel are respectively provided with a controllable open front cover 6 and a rear cover 7. There are also two or more front return channels 4 in the reduction gear, and one port of the front return channel 4 It is connected to the inner wall of the main passage 1 by obliquely cutting towards the front mouth 2 of the main passage, and a valve 5 is provided at the connection. 1 The front openings have the same or similar orientation.

[0031] When the forward-moving deceleration device needs to decelerate, open the front cover 6, close the rear cover 7, open the valve 5, and the flu...

Embodiment 2

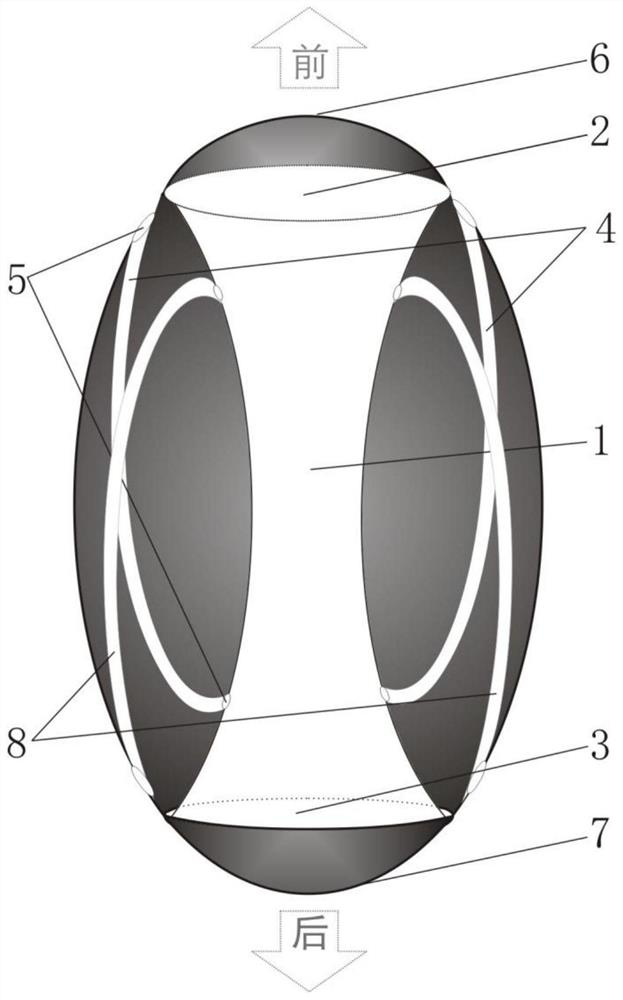

[0034] Such as figure 2 As shown, a deceleration device capable of bidirectional deceleration, on the basis of the structure of Embodiment 1, further: the deceleration device further includes a rear return passage 8, and there are two or more rear return passages 8, one port of which is directed toward The direction of the rear port 3 of the main passage is obliquely connected to the inner wall of the main passage 1, and a valve 5 is provided at the connection. The rear mouth is facing the same or similar.

[0035] When the deceleration device moving backward needs to be decelerated, the rear outer cover 7 is opened, the front outer cover 6 is closed, and the valve 5 is opened, and the fluid entering the main channel 1 is discharged in the reverse direction through the rear return channel 8, generating a backward thrust to realize rearward movement. Slow down toward a moving object.

[0036] This embodiment is a deceleration device with two-way deceleration function of a si...

Embodiment 3

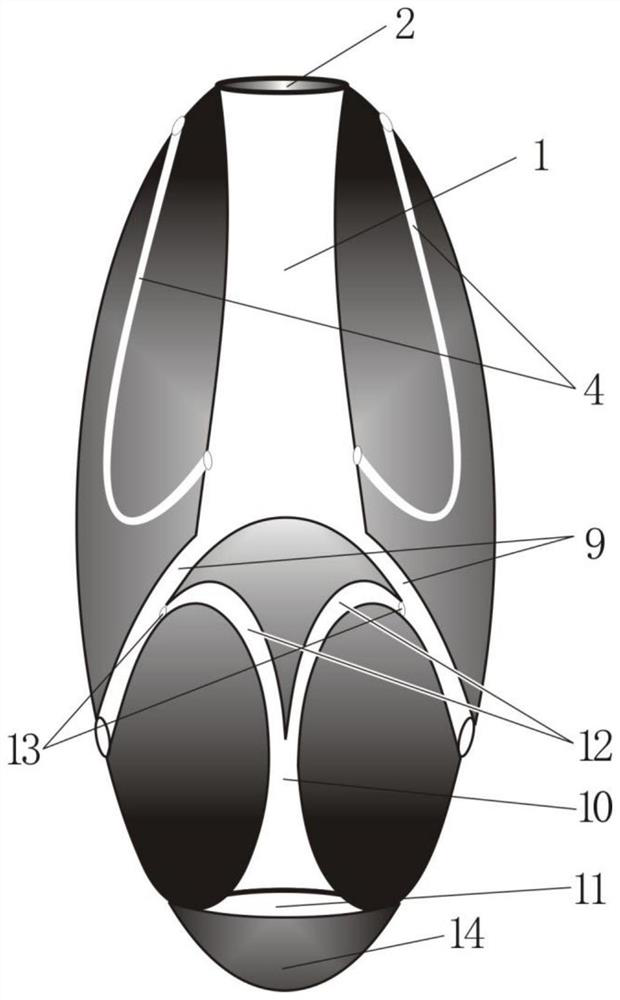

[0038] Such as image 3 As shown, a deceleration device capable of bidirectional deceleration, on the basis of the structure of Embodiment 1, further: the rear section of the main passage 1 is formed with two or more discharge passages 9, and the rear end of the discharge passage 9 is decelerating The rear side of the limit of the device forms an obliquely cut backward exhaust port; the middle position of the rear end of the deceleration device is also provided with a rear air inlet 11, and the rear air inlet is provided with a rear air inlet cover 14; 11 connected rear air intake channel 10 extends inward and divides into two or more rear air intake channel branches 12, and the rear air intake channel branch 12 communicates with the exhaust port 9 in the direction of the exhaust port of the exhaust channel 9 The inner wall, and a branch valve 13 is provided at the communication point;

[0039] When the deceleration device decelerates backwards, the rear air intake cover 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com