Submerged arc furnace electrode in-furnace depth automatic measuring system and method thereof

An automatic measurement, submerged arc furnace technology, applied in the direction of measuring devices, furnaces, furnace components, etc., can solve the problems of complex raw material production systems, mismatched adjustment ranges, restricting automation levels, etc., to prolong normal production time and improve production quality. , The effect of reducing the number of shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

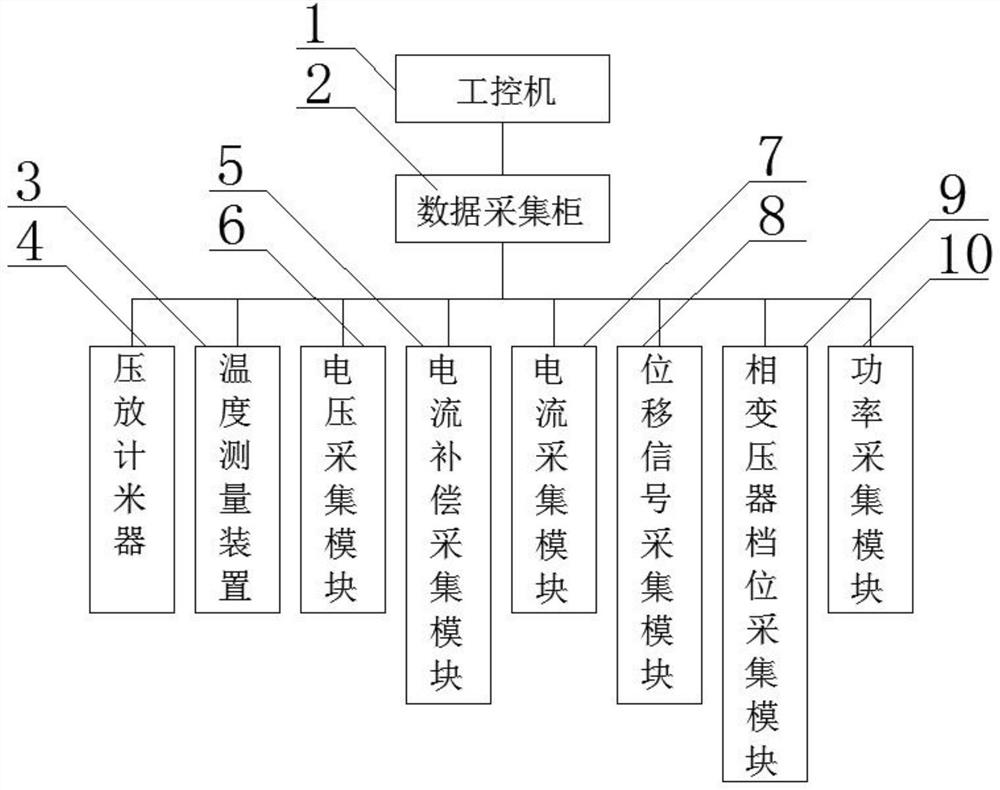

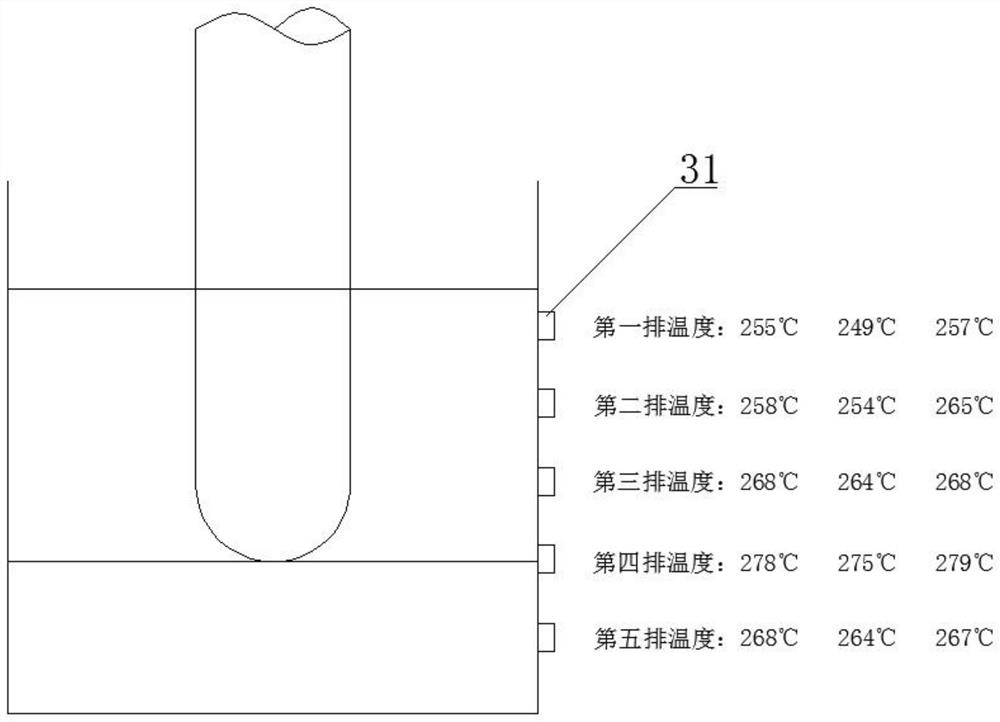

[0044] see Figure 1-2 , a submerged arc furnace electrode into the furnace depth automatic measurement system, including the submerged arc furnace electrode holder installed in the submerged arc furnace electrode holder pressure meter 4, the submerged arc furnace electrode holder 4 is installed in the fixed steel ring of the submerged arc furnace electrode holder, One electrode is installed for each phase. During installation, power outage operation is required, and it is locked and combined with protection. It is used to monitor the pressure and discharge work of the electrodes. The temperature measuring device 3 installed on the furnace wall of the submerged arc furnace is used to measure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com