Shield tunnel model test device and method

A model test device, shield tunnel technology, applied in measuring devices, instruments, mapping and navigation, etc., can solve the problems of large difference in stiffness of each ring, unsuitable deformation, inconsistent force mechanism, etc., to facilitate disassembly and installation. , easy to shovel and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

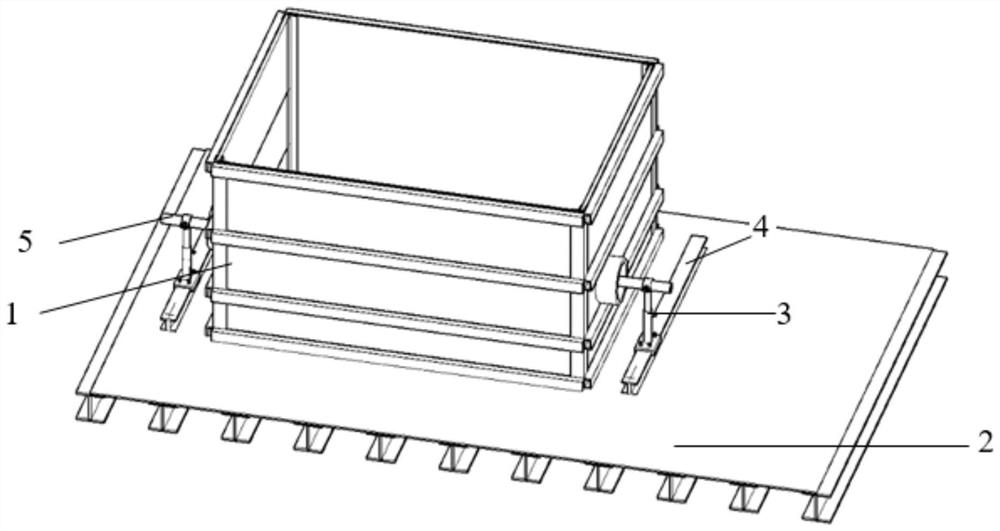

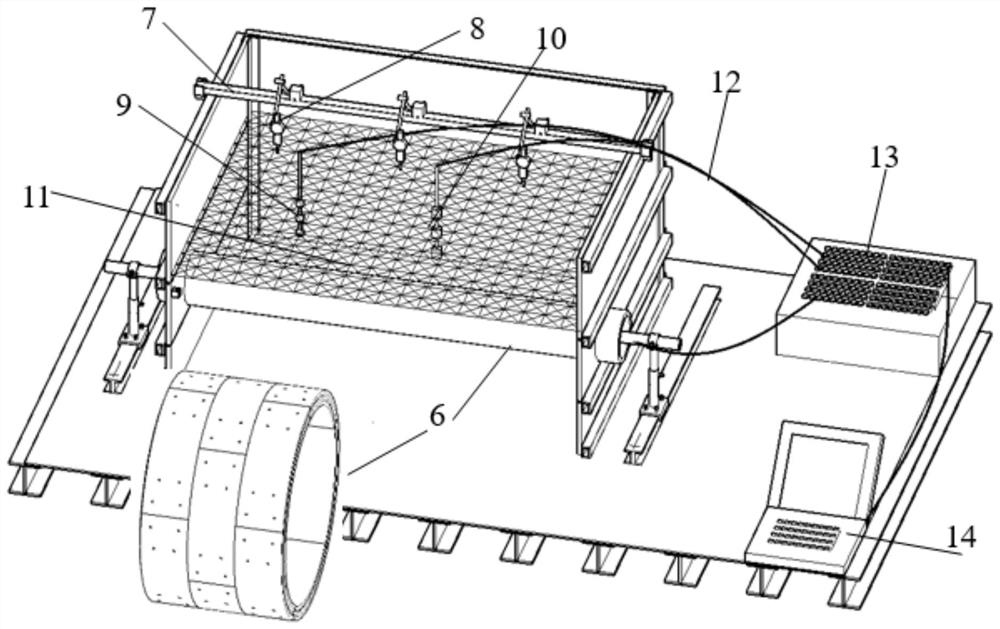

[0068] Embodiment 1 of the present application provides a shield tunnel model test device, using 3D printing technology to produce a complete set of model test devices that can truly simulate the external load of a shield tunnel under various stratum environments. The model tunnel segment The force mechanism is consistent with the actual tunnel segment, the manual assembly is relatively simple, and the displacement gauge is easy to install inside the tunnel. Its structure includes model box 1, base 2, reference rod fixed support 3, slide rail 4, tunnel displacement reference rod 5, model tunnel 6, soil top surface settlement reference rod 7, soil top surface settlement percentage indicator 8, Micro earth pressure gauge 9, micro pore water pressure gauge 10, simulated soil 11, sensor wire 12, signal acquisition instrument 13, computer 14.

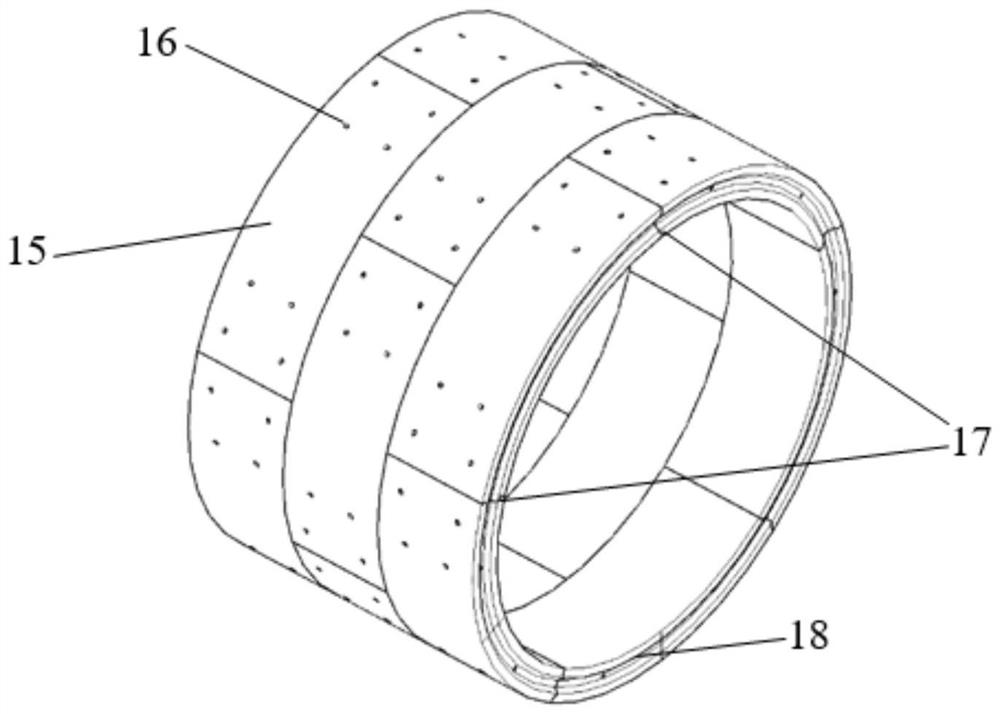

[0069] Firstly, the printing of the model tunnel segment 15 is carried out. Draw the segment model file on the computer, the inner diamete...

Embodiment 2

[0078] Embodiment 2 of the present application provides a method for installing a shield tunnel model test device, comprising the following steps:

[0079] S1. Purchasing a sufficient amount of fine sand, gypsum, fly ash, and barite powder according to the test needs to ensure that the test site is connected to water and electricity. Pour fine sand, gypsum, fly ash, barite powder and water into the mixing tank according to the proportion, and use a mixer to stir the materials in the tank. After the mixing is completed, the materials are mixed into mud water, and these mud water is poured into the large material Leave to stand in a bucket. After standing still for a week, scoop up the clear water on the inner surface of the bucket to prepare the simulated soil 11.

[0080]S2. Weld the four columns 31 to the base 2, and insert the front and rear baffles 30 of the model box into the front and rear baffle slots of the columns 31. First insert the lower plate 27 of the two plexig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com