Chemical reaction conversion rate prediction method and system based on deep learning, and medium

A technology for chemical reactions and prediction methods, applied in the field of chemical reactions, can solve the problems of weak model versatility, insufficient use of reactant information, insufficient consideration of the influence of reaction formula and conversion rate, etc., to achieve the effect of improving prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

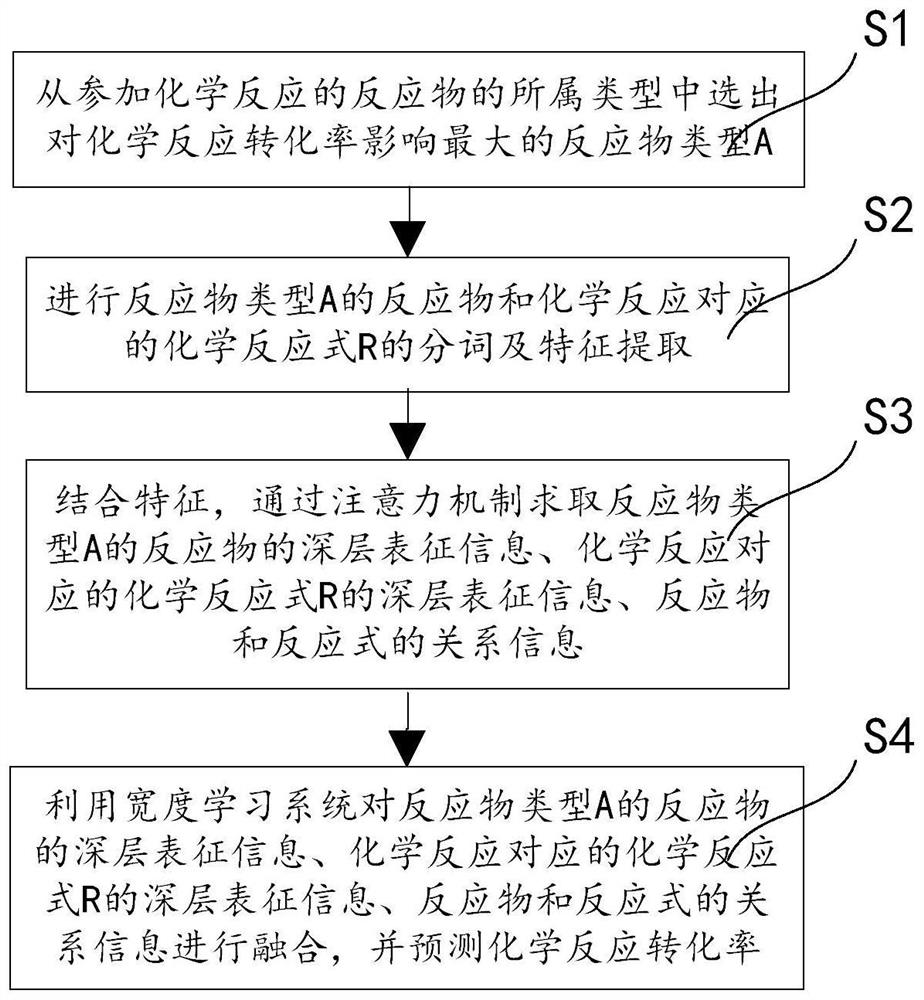

[0058] Such as figure 1 As shown, the chemical reaction conversion rate prediction method described in this embodiment comprises the following steps:

[0059] S1. From the types of reactants participating in the chemical reaction, select the reactant type A that has the greatest impact on the conversion rate of the chemical reaction;

[0060] Specifically, according to the number of different molecules of each reactant type, the reactant type with the largest number of different molecules is taken as the reactant type that has the greatest impact on the conversion rate of the chemical reaction.

[0061] S2. Carry out the word segmentation and feature extraction of the chemical reaction formula R corresponding to the reactant of the reactant type A and the chemical reaction, and obtain the corresponding feature X r and x a ;

[0062] Specifically, this step specifically includes:

[0063] S2-1. Convert the reactant of reactant type A and the chemical reaction formula R corr...

Embodiment 2

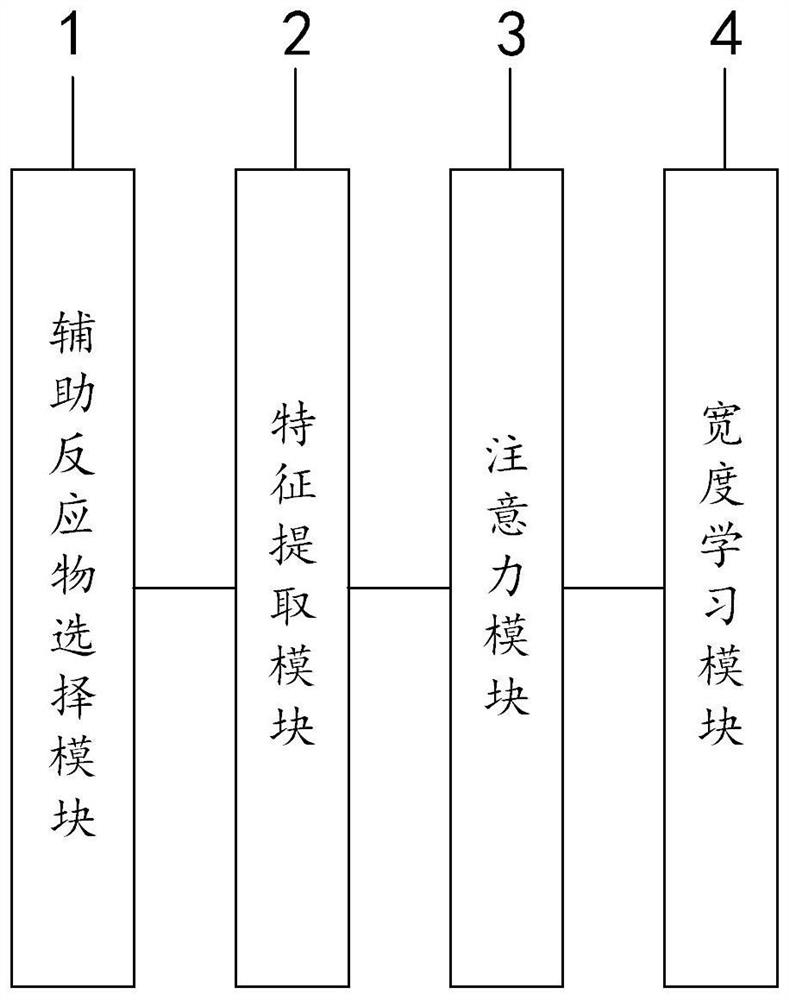

[0098] Such as figure 2 As shown, the chemical reaction conversion rate prediction system described in this embodiment is used to realize the above-mentioned chemical reaction conversion rate prediction method, which includes an auxiliary reactant selection module 1, a feature extraction module 2, an attention module 3, and a width learning module 4;

[0099] in,

[0100] The auxiliary reactant selection module 1 is used to select the reactant type A that has the greatest influence on the conversion rate of the chemical reaction from the types of reactants participating in the chemical reaction;

[0101] The feature extraction module 2 is used for the word segmentation and feature extraction of the chemical reaction formula R corresponding to the reactant of the reactant type A and the chemical reaction, and obtains the corresponding feature X r and x a ;

[0102] The attention module 3 is used to obtain the deep representation information T of the reactants of the reactan...

Embodiment 3

[0105] This embodiment is a computer-readable storage medium, where a computer program is stored in the computer-readable storage medium, and the computer program is configured to realize the steps of the above method for predicting the conversion rate of a chemical reaction when invoked by a processor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com