Oscillation control and optimization method of SOFC system caused by water vapor flow oscillation

An optimization method, water vapor technology, applied in fuel cell control, electrical components, electrochemical generators, etc., can solve problems such as long experimental period, SOFC power generation system can not work normally, inappropriate oscillation control, etc., to achieve optimal performance performance , Improve the control effect, prevent the spread of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

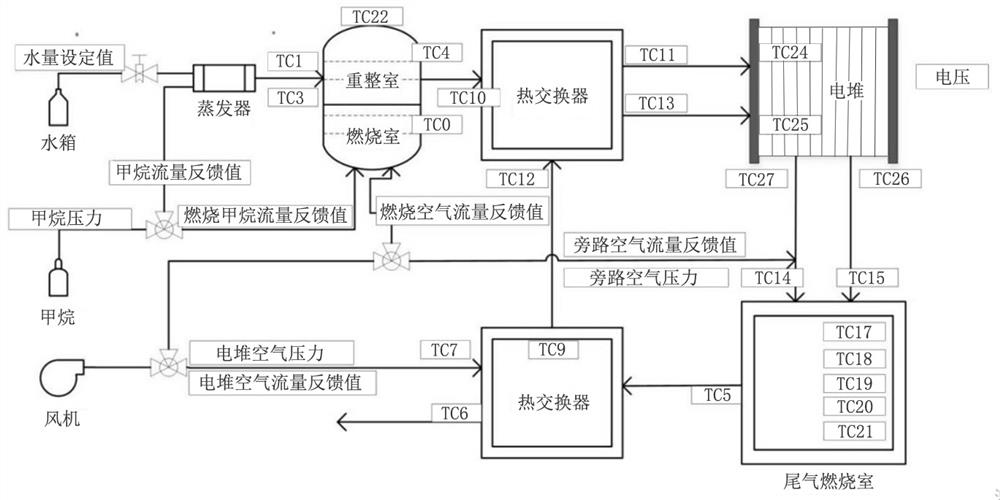

[0096] Such as Figure 1-Figure 42 As shown, this embodiment provides a SOFC system oscillation control and optimization method caused by water vapor flow oscillation, including the following steps:

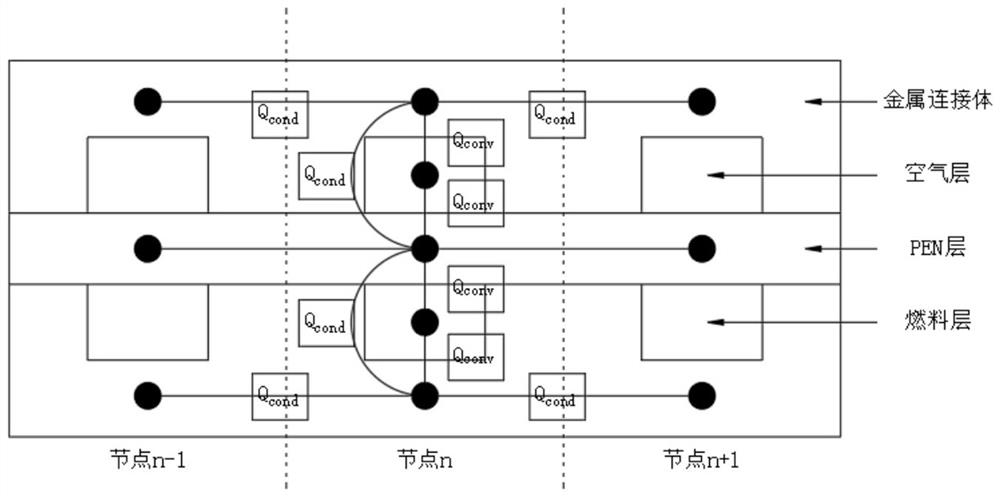

[0097] S1. Carry out modeling of SOFC system for external steam reforming as the basic support for subsequent control and optimization methods;

[0098] S2. Assuming that the irregular oscillation change of the methane flow rate other than the specified input is only affected by the change of the water vapor flow rate, simulate and analyze the situation of the water vapor flow rate oscillation;

[0099] S3. Introduce an oscillation control algorithm based on fuzzy control, and propose corresponding control and optimization strategies for the root cause of SOFC system oscillation caused by water vapor oscillation;

[0100] S4. Based on the simulation experiment results of the two fuzzy controllers, respectively analyze the optimization effects of the two strategies, and apply the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com