Electric drive unit for motor vehicle

A technology for electric drive units and motor vehicles, which is applied to the arrangement of cooling combination of power devices, mechanical equipment, power devices, etc. It can solve problems such as difficulties in the lubrication process, achieve smooth flow, and improve the effect of oil extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

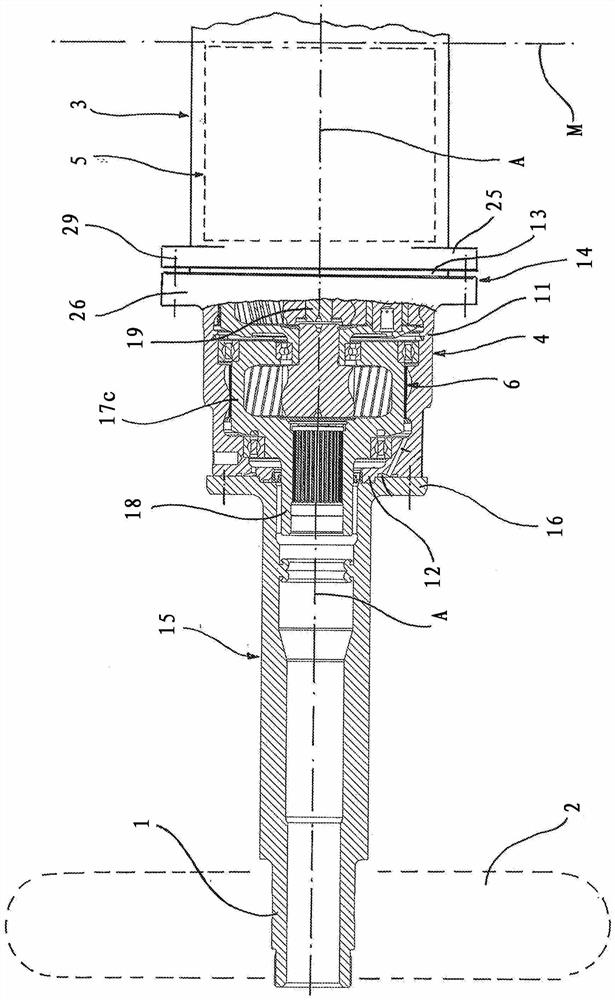

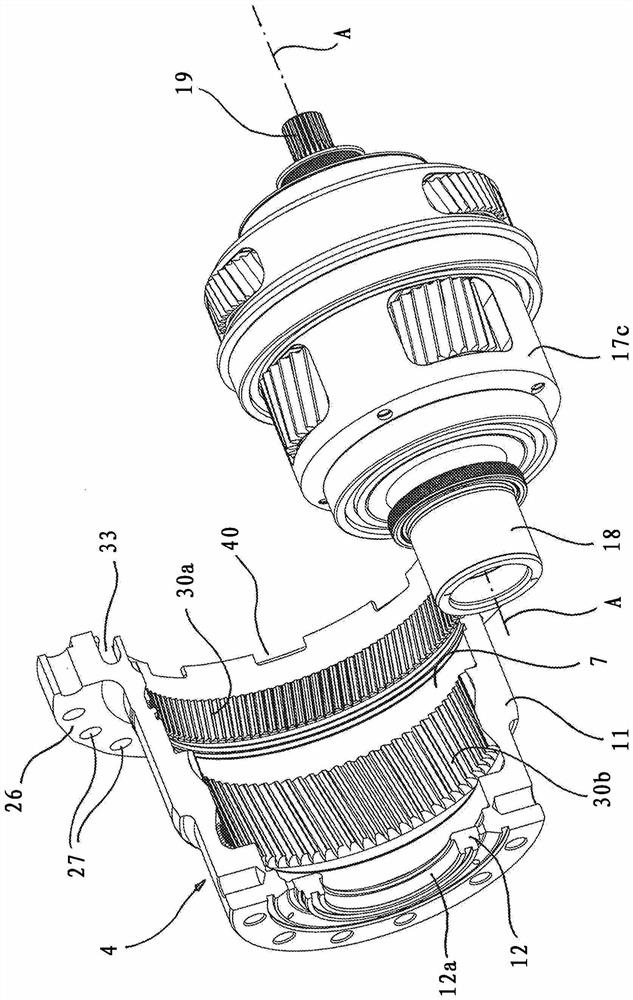

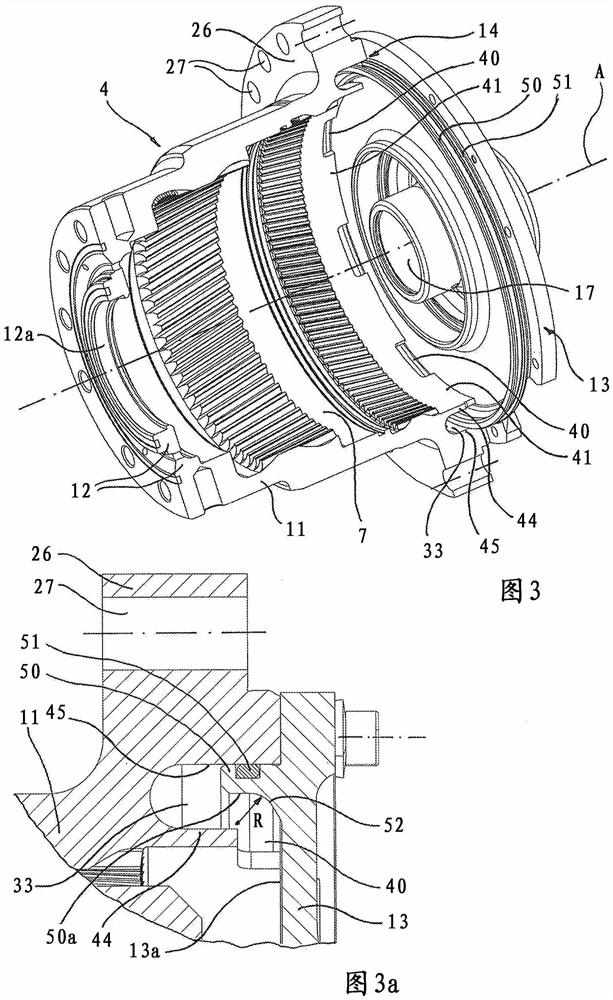

[0031] figure 1 A schematic illustration shows half of an electric drive shaft for a motor vehicle. The shown half of the drive shaft is used to drive the figure 1 Wheel 2 is shown with a dotted line on the left edge. The second half of the same design of the drive shaft is located symmetrically on the figure 1 The other side of the mid-plane M of the vehicle drawn in and supports the corresponding wheel on the other side of the vehicle. The electric drive shaft is in its entirety a continuous rigid shaft from one vehicle side to the other.

[0032] For each vehicle side and for driving the respective wheel 2 , an electric drive 5 , in particular an electric motor, is arranged in the vicinity of the mid-plane M of the vehicle. Downstream of each electric motor toward the exterior of the vehicle is a transmission 6 , here in the form of a two-stage planetary transmission.

[0033] The two electric drives are located in a common motor housing 3 , which can be one-piece or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com