Roller kiln with tail gas treatment system

A technology of tail gas treatment and roller kiln, which is applied in the direction of moving filter element filter, using liquid separation agent, filtration and separation, etc., can solve the problems of poor tail gas purification effect, achieve scraping and improve tail gas purification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

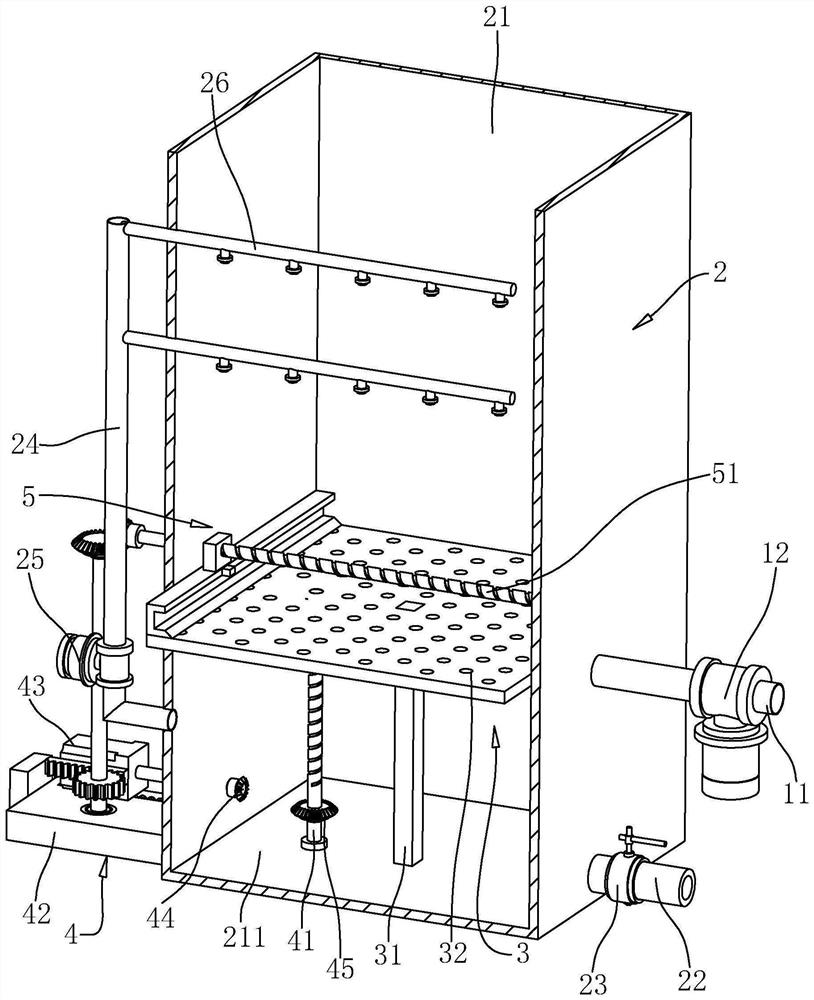

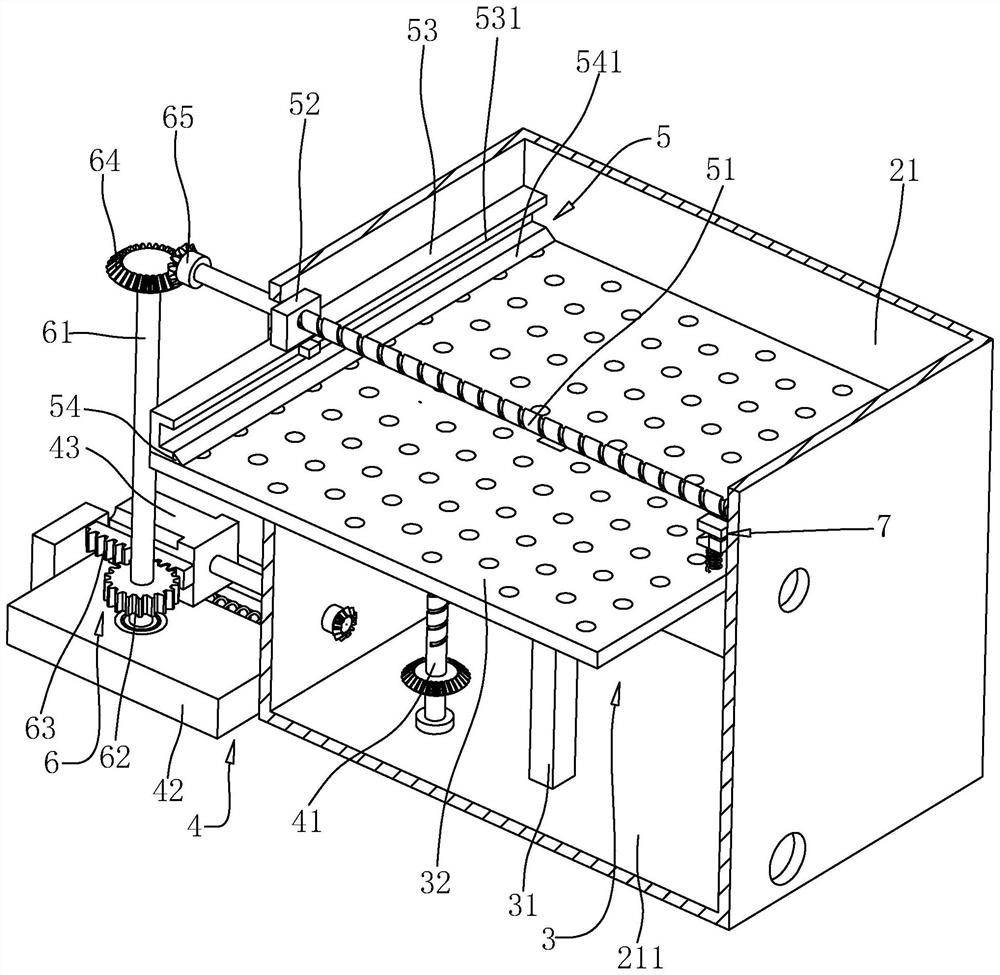

[0033] Contraction below Figure 1-5 Further detailed description of the present application.

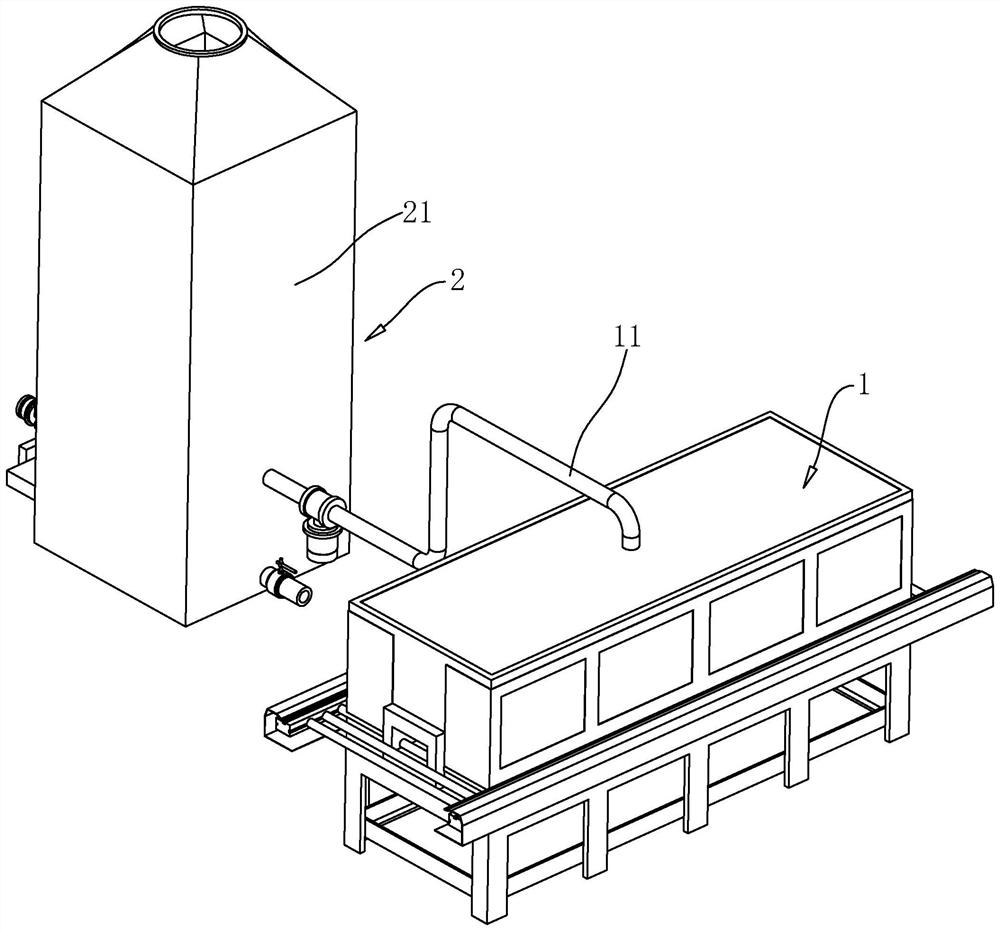

[0034]The present application discloses a roller kiln with a tail gas treatment system. Refer figure 1 and figure 2 The roller kiln of the tail gas treatment system includes a roller kiln body 1, and the tail gas pipe 11 is fixedly connected to the top of the roller kiln body 1, and the exhaust gas pipe 11 is provided with a first valve 12; one side of the roller kiln body 1 There is an exhaust gas treatment device 2, the exhaust gas treatment apparatus 2 includes a processing tower 21, a water pipe 22, a second valve 23, a pumping pipe 24, a water pump 25, and a spray tube 26; the processing column 21 is disposed on one side of the roller kiln body 1, The exhaust pipe 11 is fixed from one end of the roller kiln body 1 and the treatment tower 21 is fixed, and the bottom portion of the treatment tower 21 is provided with a water storage chamber 211, and the exhaust gas pipe 11 is in commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com