Meat grinder with good safety

A safety and meat grinder technology, applied in the meat grinder field, can solve the problems of permanent wounds, no setting, brought into the meat grinder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

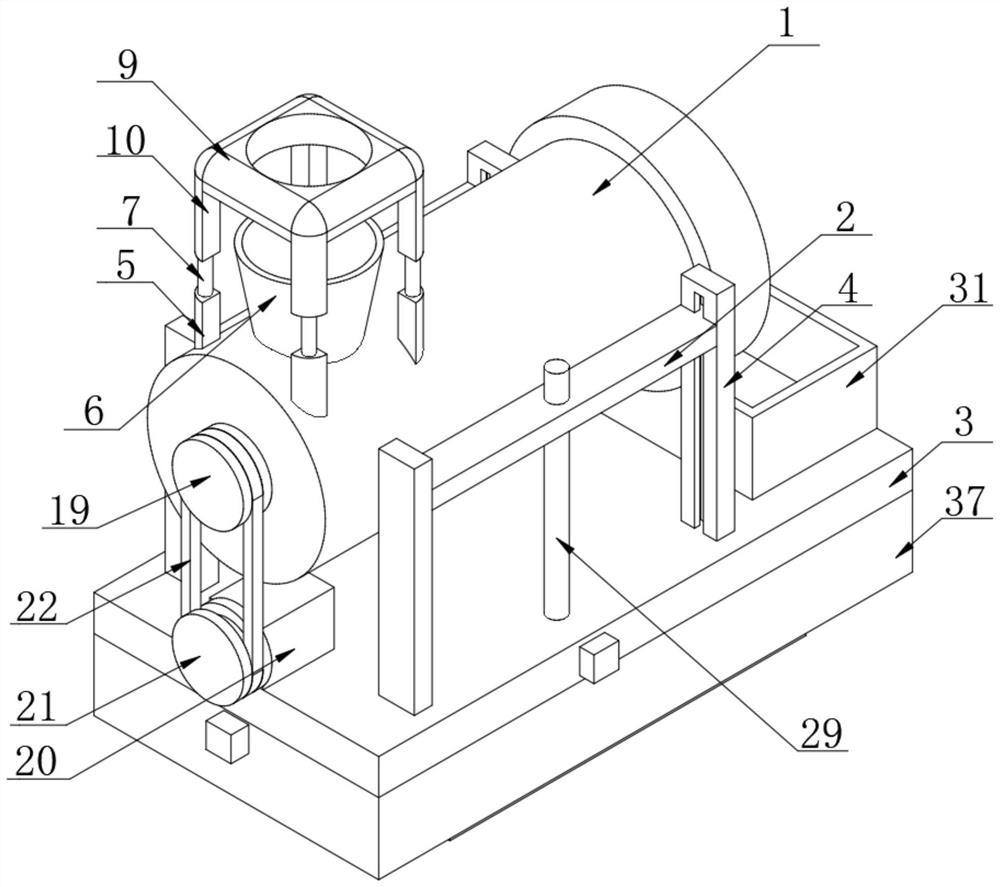

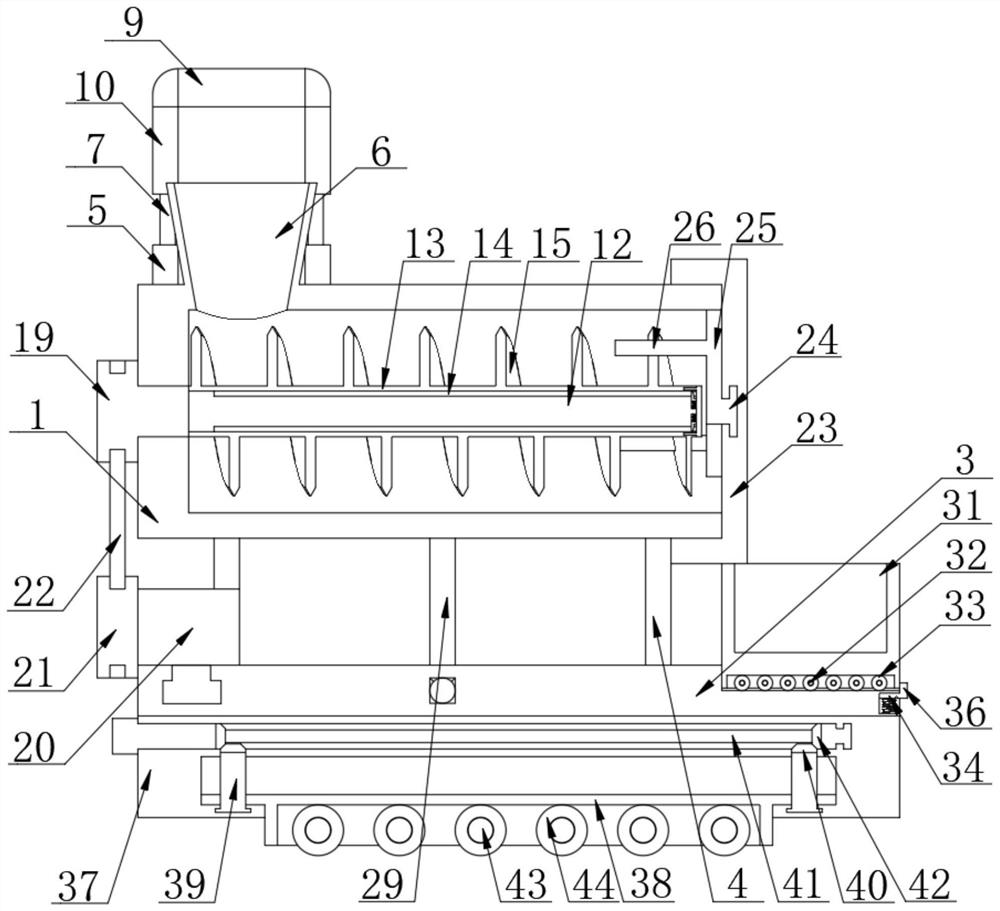

[0033] Refer to attached Figure 1-6, a kind of meat grinder with better safety provided by the present invention comprises machine barrel 1, and both sides of described machine barrel 1 are fixedly connected with support plates 2, and the top of described machine barrel 1 is provided with protective mechanism, and described machine barrel 1 A base 3 is provided at the bottom of the cylinder 1, and support rods 4 are fixedly connected to both sides of the top of the base 3, and a first slide groove is provided on one side of the support plate 2, and the support plate 2 is arranged inside the first slide groove and Slidingly connected with the support rod 4, the top of the base 3 is provided with a support mechanism;

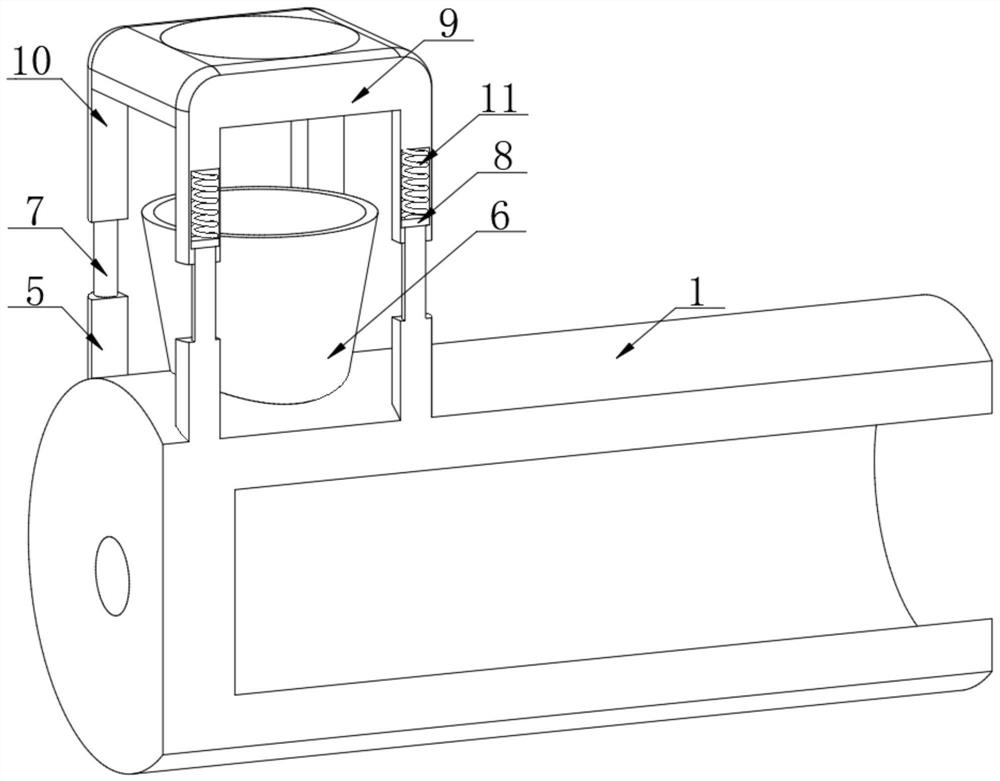

[0034] The protection mechanism includes a plurality of fixed rods 5, which are distributed in a circular array, and the bottom of the fixed rods 5 is fixedly connected with the outer top of the machine barrel 1, and the outer top of the machine barrel 1 is provi...

Embodiment 2

[0041] Refer to attached Figure 7-10 , a meat grinder with better safety provided by the present invention, the support mechanism includes a first rotating rod 27, a first internal groove is opened on one side of the base 3, and the first rotating rod 27 is arranged on the second The inside of an inner groove is rotatably connected with the base 3, one side of the base 3 is fixedly connected with a second motor, one end of the first rotating rod 27 is fixedly connected with the output end of the second motor, and the two outer sides of the first rotating rod 27 are Both ends are fixedly connected with the first bevel gear 28, the top of the base 3 is provided with a rotating hole, the inside of the rotating hole is provided with a first threaded rod 29, and the first threaded rod 29 is located inside the rotating hole and is connected to the base 3 Rotationally connected, the bottom of the first threaded rod 29 is fixedly connected with a second bevel gear 30, the second beve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com