Stamping die applied to motor shell production and machining method

A technology for stamping dies and motor casings, which is applied in the field of motor casing processing, can solve the problems of unfavorable promotion and use, difficult maintenance and maintenance, and high enterprise use costs, achieve excellent user experience, easy maintenance and maintenance, and reduce processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

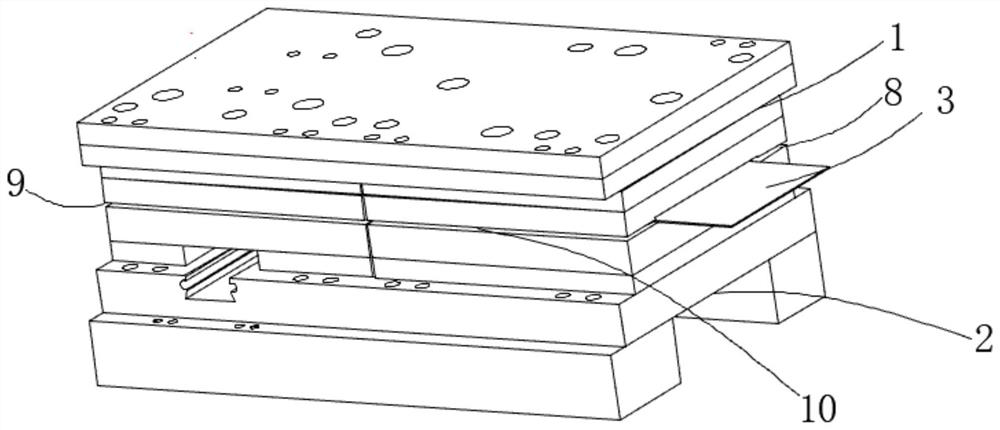

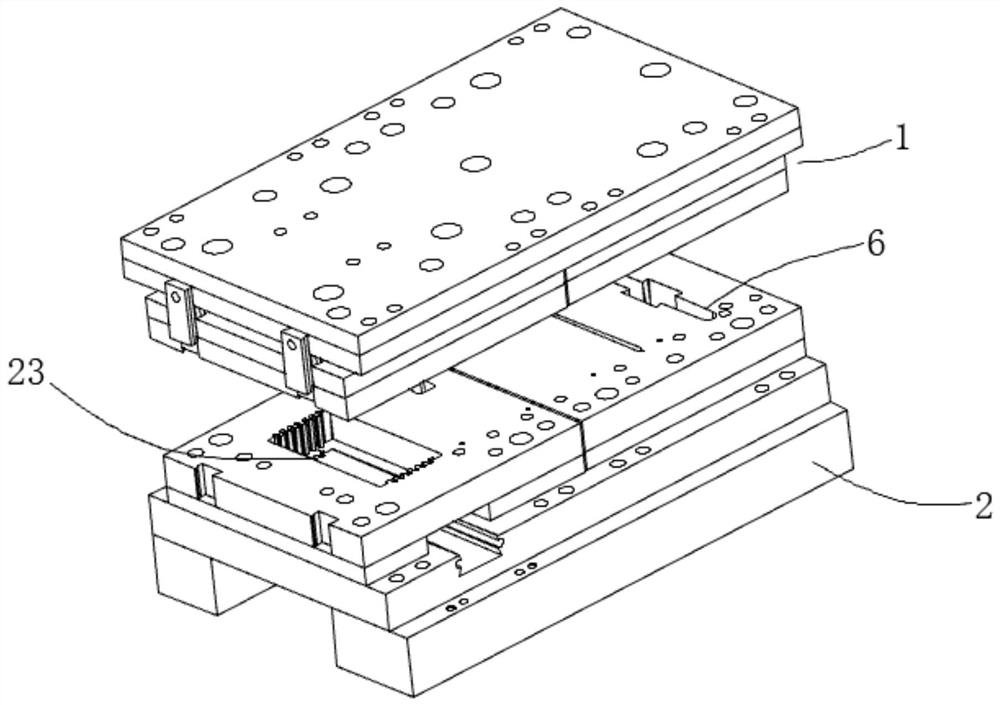

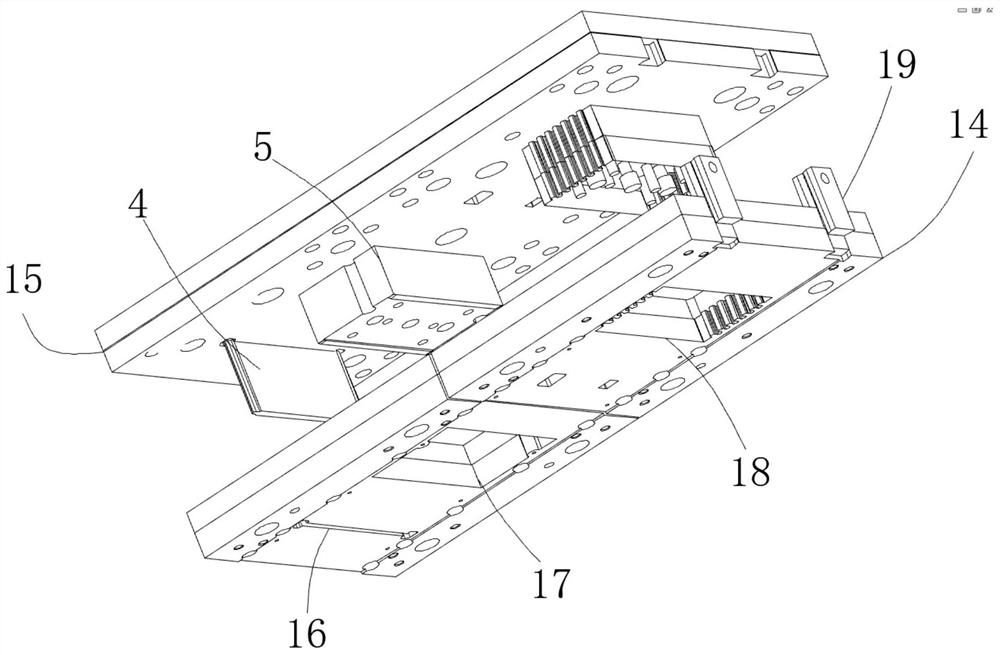

[0033] A stamping die and processing method applied to the production of motor casings according to the present invention will be described in conjunction with the accompanying drawings.

[0034] Such as Figure 1-Figure 6 Shown, as a kind of preferred embodiment of the present invention:

[0035] A stamping die applied to the production of motor casings, comprising an upper die 1 and a lower die 2 arranged up and down, a stamping area 10 is formed between the upper die 1 and the lower die 2, and a feeding material is arranged on the stamping area 10 port 8 and discharge port 9, the upper die 1 is provided with a first punching head 4 and a second punching head 5 in sequence along the direction from the feed inlet 8 to the discharge port 9, and the first punching head 4 is used for A strip-shaped opening is punched out on the material 3, the second punching head 5 is used to punch out a step at a position close to the opening, the lower die 2 is provided with a blanking groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com